I am having an issue, my GF Pro stops cutting through material after several cuts. It misses by less than an mm. If I push hard I can break the material along the cut line. I have tried many things, including cleaning optics, changing lens, slowing down (it does help), making sure the GF is flat and level etc. So far the only thing that works for me is to run the camera calibration tool. Once it stops cutting, I run the camera calibration tool, and then it starts cutting again. No other changes needed. Not sure how the camera calibration relates to cutting, but that’s what is working for me. It seems running the camera calibration updates some setting, that drifts after some time. My camera is pretty well calibrated. Running the camera calibration doesn’t find any improvement. The target test aligns perfectly. But just running it makes it cutting again. I have been running like this for awhile now. Either slow down the cutting speed or run the camera calibration to use proof grade cut settings. I was hoping someone here can explain why running camera calibration works. It may point to what is wrong with my unit.

I did contact support, they tried several things and then suggested to buy a refurbished unit. It seems like the unit needs some minor adjustment and I don’t want to send it back. Since it cuts after the camera calibration, the laser and the mechanical components are fine.

To my knowledge, the lid camera calibration does not affect anything except alignment - nothing whatsoever to do with cutting. You are much better off cleaning the optics and fans and adjusting the speed and power. All of those things do enter into the performance of the Glowforge.

When you run the gift of good measure file on proof grade does it work correctly?

That will tell you if the machine has a problem or not.

The camera calibration updates some numbers used in software to dewarp the fisheye camera image to produce a more accurate flattened image. It’s just a visual aid to the human operator, not an input to anything the machine does when cutting/scoring/engraving.

If it’s helping with your cutting problem, it must be through some second order effect… something like: it’s getting overly hot after doing several full power cuts, running the camera calibration gives it time to cool down, and it cuts better when cool. That’s just a guess with no evidence backing it up, but there’s no way the camera calibration can be directly fixing the problem.

How old is the machine and how often do you use it to cut things? If it’s 2+ years old you may be seeing your laser tube reaching its end of life, when power output starts to drop. If that’s the case, Glowforge Inc can buy you some time by slowing down all your Proofgrade settings, but the only long-term fix is to replace the tube (which GF currently only does by replacing the whole machine).

When it stops cutting, it won’t cut through gift of good measure on proof grade medium draft board. However after running the camera calibration, it cuts through.

Thanks dan84. I also thought the same thing. The camera calibration is giving the machine time to cool down. I tested by shutting down the machine for an hour. No luck. Then it starts cutting after I run the calibration. Based on what you are saying about camera calibration, it must be some side effect. Just don’t know what. The machine is from February 2021, so just about 2 years old.

You haven’t mentioned if you’re using ‘set focus’? The only thing I can think of the calibration is doing is improving your default focus. Both autofocus and set focus tell the machine what it it thinks the material thickness is (unless you override by inputting your own #) which affects where the focal point of the beam is and affects cut through if not set correctly. If you’re not using ‘set focus’ yet give that a try. Most of us use it every cut.

Thanks Ekla. Yes, I use set focus for every cut. I thought everyone does that, that’s why didn’t mention it separately.

You’d be surprised how many people have never heard of it ![]()

Happy Friday everyone.

Last night the GF stopped cutting through again, so I decided to run a series of tests to see If I can isolate why it starts working after running camera calibration. Documenting the results here. Hoping someone can see something I missed.

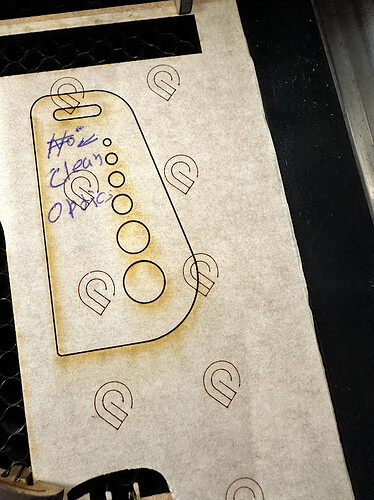

All tests are done with proof grade medium draft board, and the gift of good measure file. I ignored the score and engrave lines to make it run faster. I used set focus before all cuts and pinned down the material to keep it flat.

Test 1

Ran as it is. No adjustment or cleaning. The machine did a few more cuts before, so not a fresh restart.

It didn’t cut through. However if I had pushed harder, I could have pushed the piece out, by tearing the masking.

Test 2

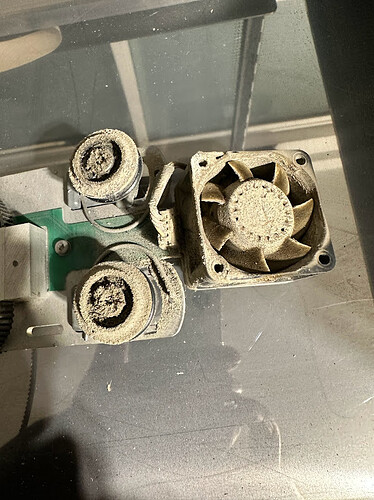

Shutdown the GF. Cleaned lens, cleaned the camera and focus windows at the laser head bottom, cleaned camera and the window/mirror on the left side. Cleaned mirror. Most of it was clean anyway. There were minor dust on the lens. The machine was off for 5 min. or so, before I turned it on for the cut.

It didn’t cut through. Can’t push the piece out without significant force. Seems it was worse than the last test.

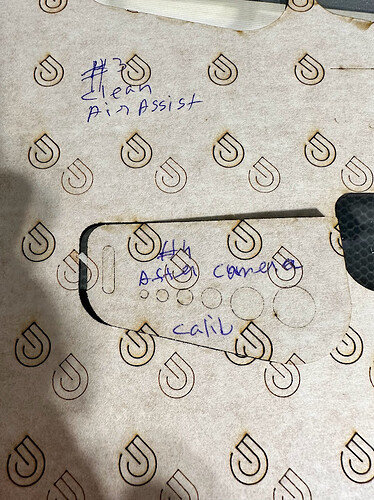

Test 3

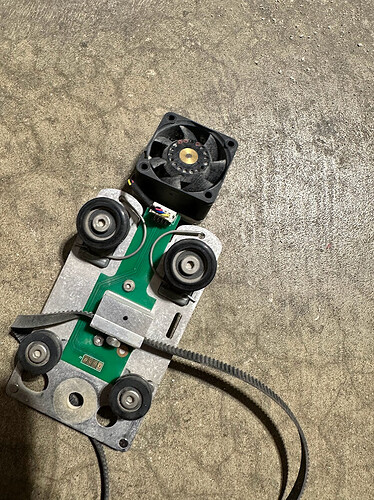

Shutdown the GF. Decided to clean the air assist fan to see if it helps. I came across the procedure recently in GF support pages, and realized I never cleaned it. Removed the belt and carriage plate, and followed the process documented at - https://support.glowforge.com/hc/en-us/articles/360034142513-Cleaning-Your-Air-Assist-Fan

It took me 30 plus minutes to clean the fan. It was quite satisfying.

Turned on the unit and did the test cut. Didn’t cut through at all. This is the worst result so far. Seems it is progressively getting bad.

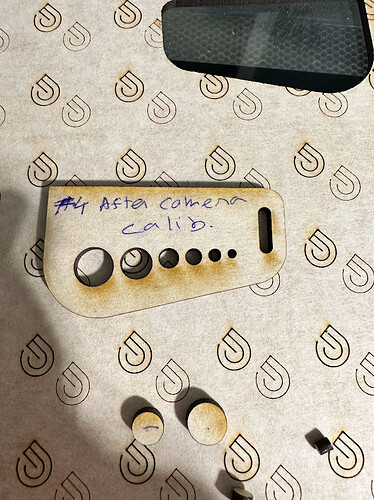

Test 4

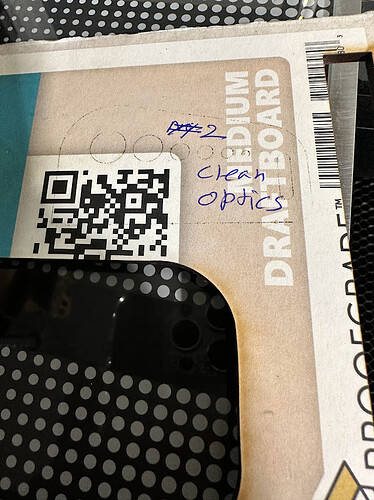

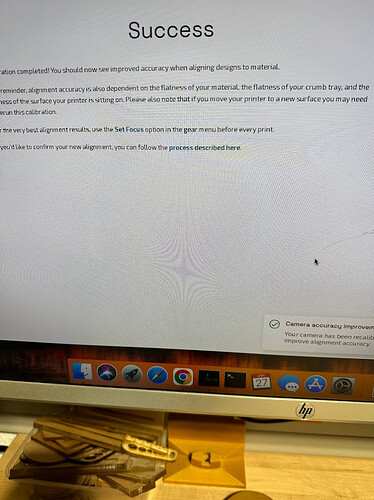

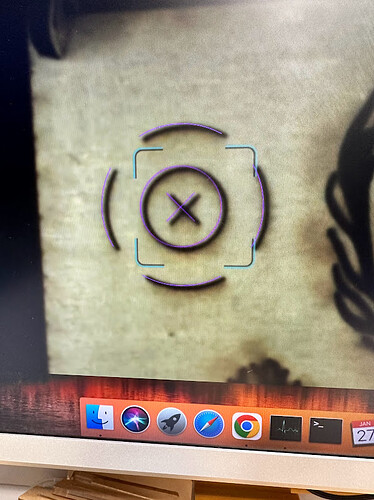

Ran the camera calibration with a blank board. This time it found some improvement. Once the calibration completed, did the alignment test. It’s pretty good, may be 1 mm or less off, but good enough. I have had better alignment test result before.

Did another test cut. It did cut through this time. Running the camera calibration process made it cut again. The mystery remains!

I did two more cuts with 3mm and 6mm acrylic. No issues. I am sure it will drift again and will stop cutting.

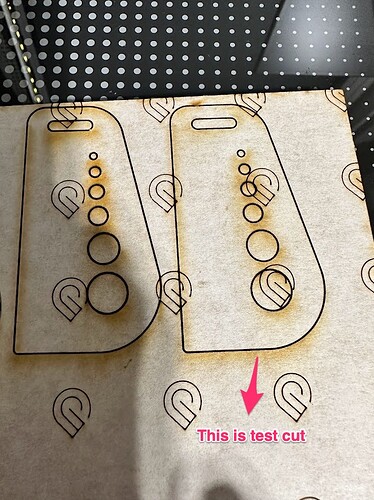

One more test last night.

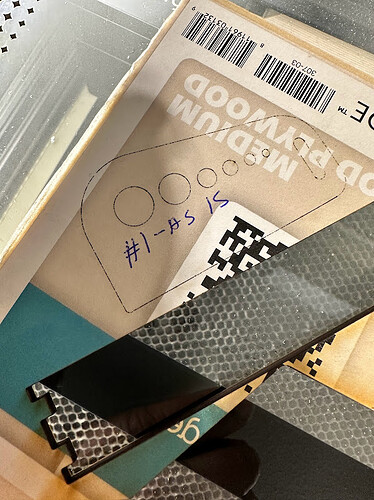

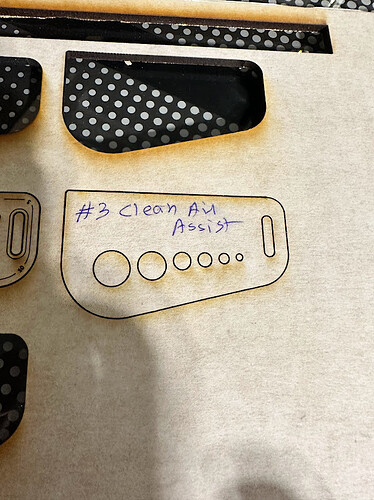

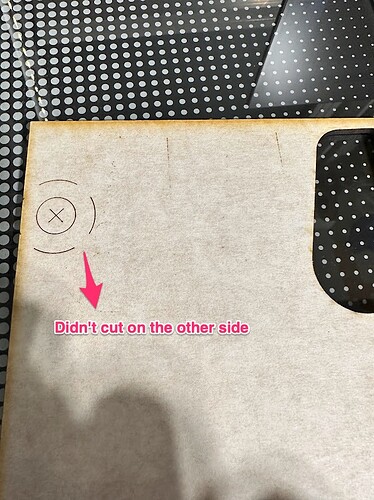

This is before running camera calibration. Didn’t even get to the other side.

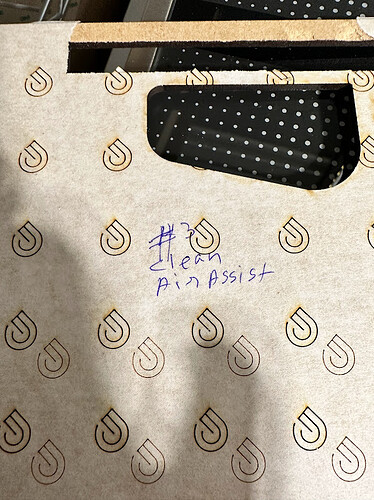

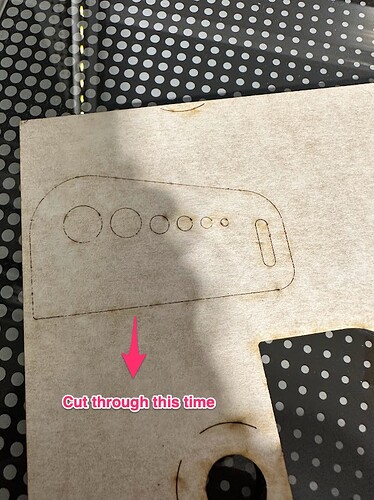

This is after running camera calibration. It cut through, and I could easily push out the piece.

Definitley running camera calibration does something that makes the GF cut through.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.