That looks great! Ticking away.

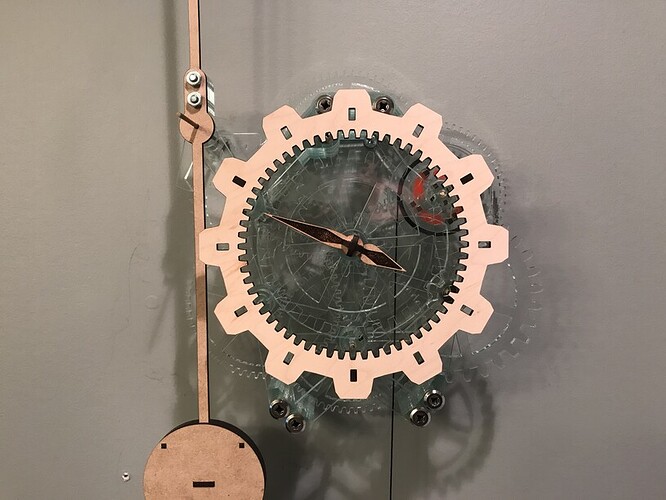

The clock has been running well, with one exception. The escapement axle has been slipping out of place. I have placed tape over the axle holes for now to prevent this. It wasn’t an issue before I cut the axles down, but when I reduced their mass it must have allowed for more shifting.

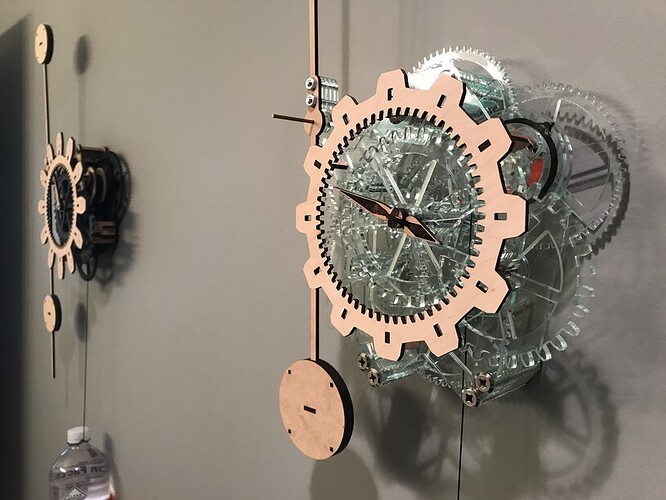

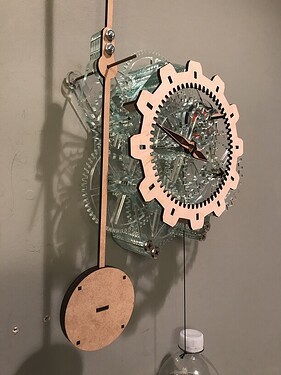

Here are some more pictures with the new face.

The old wooden version in the background. It has stopped running even for a few seconds.

I am still trying to slow it down. It is running to fast, so I might need to work on the pendulum again, but I really think I need a break and really just want to enjoy the clock.

I still need to design a proper weight; something to hold the metal balls I purchased for the weight of the clock, but the water bottle has been working so well.

Just a thought. They sell fancy Finials of iron and brass cheap enough to get several to try for the look and weight you want. You would only need to make some interface so you could hang them.

I think that could look really cool, but I also want something that won’t mark up the wall…

A little self-adhesive felt applied to the back would take care of that.

If nobody is swinging on it it should not move much and as @jamesdhatch mentioned you can add bumpers on the wall side. It should also be obvious they would all be upside down from as pictured. A clear acrylic interface could also keep it off the wall by hitting before the iron did.

I am having trouble slowing the clock down without stopping it.

If I let it run fast, it just keeps going, but I try to slow it down to make it actually keep time it will stop… This can be so frustrating. I am so close, I just want to get it over the finish line.

The period of the pendulum is determined by the length, but the mass of the bob might have to be increased to keep it running as you move the bob closer to the end of the shaft.

I am using a compound pendulum, so the rules are a little different. But I do need to adjust the weights at the top and bottom.

The clock has been running for around 6 six days (still fast), but in that time it has only stopped once (except if I am winding it). I think something (wind of kid running by?) stopped the pendulum? Not sure exactly why, but it seems stable most of the time… just to fast.

That exactly is the reason old pendulum grandfather clocks are enclosed in a wood/glass cabinet. A slight breeze running through the house very easily unbalances the pendulum.

A rectangular tube on the wall of clear acrylic that covered the path pf the pendulum could solve that and still look good,

I would love to make an enclosed mantle clock.

But to enclose the compound pendulum would be best to adjust the pendulum some more. The pendulum going up so high is a little strange, it almost seems like the clock is upside-down…

?? it could be a box open at top and bottom that could just hang on the wall and just take down while changing the pendulum.

The pendulum is the part of the clock that probably needs the most attention. I feel really good about the rest of the clock.

I think it needs to have some balance adjustments too. The swing is off-center when the “beat” is correct.

After playing with the clock for a while now I feel like the ratchet was great addition for the winding, but I think it could still be greatly improved with a counter-pull for the rewind.

If I extend the drum and add a second cord to pull just to wind the clock it should make it much easier to wind. But one concern is that the counter-torque could squeeze the drum on the axle and add resistance to the rewind. Another concern would be to make sure the added force does not shift the balance of the clock on the wall, upsetting the delicate “beat” of the clock.

The clock is stopping again, just like all the others…

I think being hung on the wall is just to much for the frame over time still…

I think it is time to go back to the drawing board and design a mantle/desk version that can support itself.

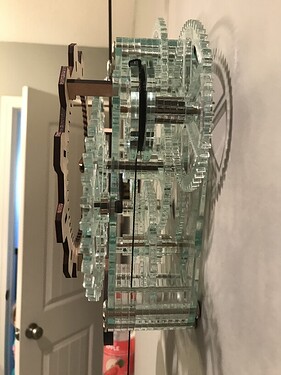

From what I learned with the ratchet (yes, it was a pain, but I learned a lot) I think I need to give a little more attention to the gears again. And if I can create a free-standing version, I should have less issues with the frame shifting.

Work has been crazy busy lately, but I still have ideas swimming around in the back of my mind…

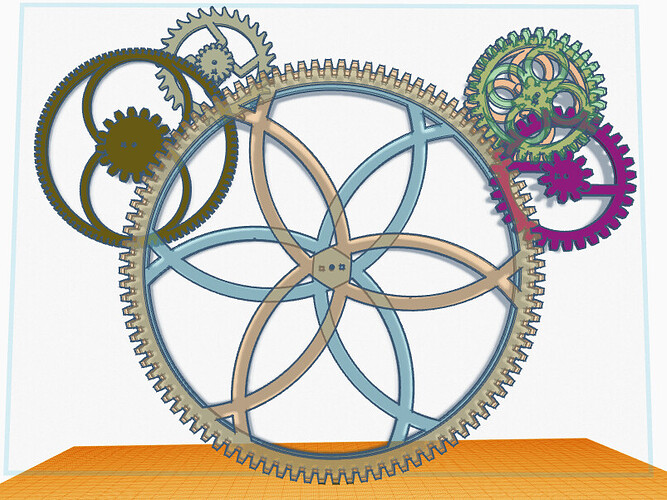

I am playing around with some new ideas…

Animated here:

I am looking to get rid of the cross axle and playing with ideas that can utilize all brass axles (non-fixed).

What I am attempting to do is find a different way gear-down the minute hand for the hour. I want to rid myself of the need of a fixed axle.

No idea what I want the frame to look like yet, but I really like the overlapping gears on the same axle. (I just hope I can get it to work.)

Currently, I plan on the ratchet and drum to be attached to the minute gear (somehow).

I can see making each gear in a different color acrylic you can see real-time how long you are mesmerized by watching the gears moving about ![]()

A new concept in second hand might also be interesting.