Can we cut and engrave sign foam with our glowforge?

Do you mean the HDU (High Density Urethane) boards?

I have not tried this product specifically but something you should know is that urethane products will give off hydrogen cyanide gas when burned/lasered which is pretty nasty stuff.

I HAVE lasered other urethane plastics, like solid cast items I cast from molds. HDU being foam, I’m sure the laser can cut it easily but because it does have a cell structure, it may not produce a desired surface finish like you can get with traditional carving. (It cuts like butter with an X-acto)

I’m going to move this thread to Beyond The Manual before staff gets to it.

The expanded pvc ones are dangerous to both you and your machine.

Yes, HDU. OK… thanks for responding and moving.

There is a brand name of “Sign Foam” and their product is urethane, which is why I asked specifically about that to clarify that it wasnt something else like Sintra.

You’re welcome. I am sure it will cut and engrave but urethanes do tend to get melty so the quality might be questionable. The HCN gas is more of a concern that you don’t breathe so you want to make sure you dont have any leaks in your ventilation. Being foam, a good portion of it is air which means less volume of bad stuff.

Is this different from the foam board type stuff you can get at practically any department store (like WalMart) ? I have thought of doing some stacked model cuts from the foam board, but not at the expense of my laser.

OOOOhhhhhhhh…I missed that post. WOW!!! Beautiful!

And yes, I pretty much watch all the time with any paper-ish product, and stay in the room with wood.

I missed that too.

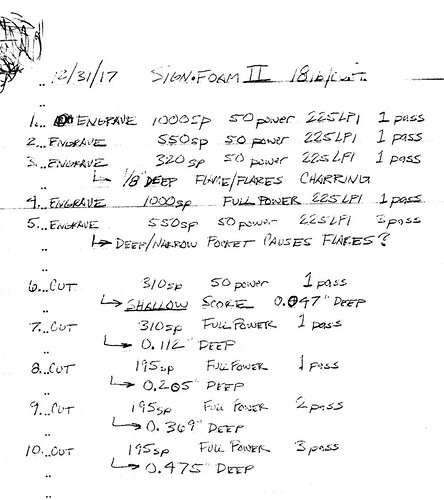

Ran some tests on a sample piece of Sign Foam that I’ve been saving for a future-yet-unknown project. ![]()

The circles are the engrave tests, in order from left to right.

The cut tests are also in order, left to right. The cutting depths that I noted below were measured as far back into the cut as I could. The cuts were semicircular paths right at the edge of the material but I had to break the insides out by hand since they obviously were not cut completely free.

If anyone has ever used a heat gun to melt/shape polystyrene foam, the texture left behind on this polyurethane foam was pretty similar.

I included a scanned copy of handwritten settings from my notebook for reference.

“saving for a future-yet-unknown project.  ”

”

…Hello, my name is Suzanne. I am a craft-a-holic…

I also save wood, fiberglass and carbon fiber sawdusts (aka: I never sweep the floors in the workshop)… you never know when you might need to scoop some up to thicken some glue.

what density was your sign foam?

18lb/cu.ft… The settings note page is labeled at the top but isnt exactly clear.