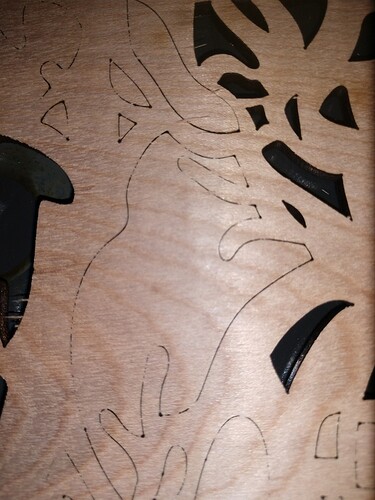

I used to cut this wood without a hitch. 1 pass at around 140/full power. Now I cannot cut it through reliably at all. There is no rhyme nor reason to it. I am trying now 2 passes at 150 and it is scorching the heck out of it. I have cleaned all the optics. Any ideas?

Check and see whether you might have put your lens in upside-down.

Is that even possible? It doesn’t attach to the “blue thingie” upside down. Does it?

When you reinsert it, it doesn’t connect to the blue thingy at all. It just sits on top of it, but you have been at this a long time so l’m guessing you know that.

Yes, it will fit upside down. So easy to do and it would do exactly what yours is doing. Don’t ask how I know…….

As well as position/orientation of the lens, be sure ALL are clean.

Then make sure the board is FLAT and pinned down–you shouldn’t hear any hollow or ping sound when you tap on it. But also wood is not homogeneous, and grain & knots have different density so each board, and even section of a board, can respond differently (PG minimizes that, but since their testing is only based on sampling, variation does happen).

Another user always suggests to slow down a bit (5-10) on the speed scale to avoid non-complete cuts. Or set up the job with 2 passes… (but going slower & more passes does increase chance of residue on the board, but if masked, not an issue to the piece).

And after a couple instances, I’ve learned to never move the board until I can feel the piece move to confirm it’s been cut through. If it feels like it’s still stuck, I run the cut job again. Though for designs you can’t do that, or forgot to check & find it’s not complete cut, often an exacto knife can be used to finish the cut.

Yes it is possible and happens frequently. It should not stick to the magnet on the blue tool when putting it back in.

Happens a lot here. Also check to see that there’s nothing in the head blocking the lens - some folks have lost the silver ring from the tool in there - came off the insertion tool and stayed in the head preventing the lens from focusing.

For each type of wood I run this test piece, It will show you what works and what doesn’t for that piece of wood. If you have masking on the back the marks from the fire bouncing back will be there and not on your work. Differences in grain will make differences in cut so a bit of overcut I find easier to deal with than a bit of undercut.

I have been paying attention to the head. The silver ring is the magnet isn’t it? I definitely still have it on the tool.

Thank you for your help everyone!

@jglazer I see you already emailed us about this and we’re working on it there, so I’m going to close this topic.