It looks pretty close. I would say it actually looks really good but you’re smelling stuff so clearly something is amiss.

There are a couple of ways that smells can get into your workspace. This is all general stuff and it may be basic, so I’m sorry if this is stuff that you already know but fundamentally ventilation is a fairly simple situation.

First you need to look at places that might be under positive pressure. Generally that means things that are after a running fan and before some sort of a blockage or resistance.

So you have three fans in the system that are relevant here. One is the intake fan on the bottom of your Glowforge, two is the Glowforge internal exhaust fan in the back left, and three is your external fan.

The intake fan pulls air into the Glowforge case and if you are impinged on the way out, it can lead to a positive pressure in the Glowforge itself and smoke will escape through the cracks in the Glowforge. This is typically caused by a dirty exhaust fan, so it can’t work at full capacity.

If you have that fan turned off in the Glowforge interface, it may still be a source of resistance if it’s a dirty fan. So now your intake fan is pulling too much air and it can’t escape the glowforge quickly enough. I would take a very careful look at your exhaust fan and make sure it’s nice and clean.

The second place where you may have positive pressure is between the exhaust fan and your in-line fan. This could be caused by having a kink in your hose from a bend that is slightly too sharp or it could be caused by the internal resistance of a particularly long hose run — which I don’t think is your issue here — or it could be caused by not running your external fan at a high enough speed or a problem with your external fan in general.

For that, I would take a close look at your exhaust fans to make sure they’re both clean, take a look at the inside of your ducting to make sure that there’s nothing stuck in there or otherwise dirty, and make sure that there’s no kinks impinging airflow between the back of your Glowforge in the front of your external fan.

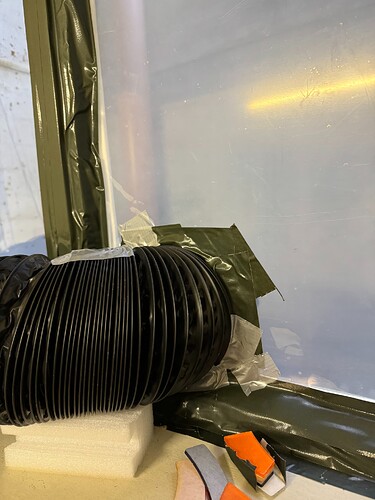

And the third place that could have positive pressure is anything after your external exhaust fan. Check very carefully to make sure that all of your seams are tightly taped and sealed, and also be wary of bends that are particularly sharp. You do have a 90° bend in that hose, but it doesn’t look like it’s kinking the hose. I think you ought to be OK but I’d check it.

If all of this checks out, your fans look like they’re functioning properly and not blocked, your hose looks like it’s running as smoothly and straight as possible without any tears or impinging… Then you have to wonder if you’re sucking fumes back in from the outside.

You’re pushing air out of your room, so more air needs to come into the room to compensate for that. It’s got to come from somewhere, and if there are any gaps in your window set up, you’ll be pulling fumes right back into the room when the Glowforge is running. Your window looks fairly well sealed with all that tape but windows are notoriously hard to seal completely.

One possibility prevent this is to extend your hose out past the window, to make your fumes further away from where they might get sucked back in through cracks. I see that you have an extension that goes out about 6 inches from the window, if you can extended a little further that might help. If you want to see the ultimate set up you should check out @dwardio ’s post. His set up is what iview as the gold standard, it uses hard pipes to reduce internal resistance and vents above his roofline. I’m still pretty jealous about that even though mine works really well.

Anyway, it looks like your set up is pretty good. I feel like you’re going to find the one thing that is a gap and you’re gonna fix it and be happy.

So, that’s a lot. How to narrow it down so you don’t have to take everything apart? For me I would work backwards and use incense to help find where the leak(s) might be happening.

First, test the window seal. Set up incense right outside the window of your workshop, then run the external fan and Glowforge at very low power while not lasering anything… And run it for a while and see if you start to smell the incense inside. You would know for sure whether or not you’re sucking in from the outside and can concentrate your efforts on the window seal.

If you run it that way and smell no incense indoors, then it’s not your window seal. Next up test the external fan. Turn off the Glowforge entirely but crank your external fan to whatever level you normally run it at. When it’s pulling air through the Glowforge, light some incense on the bed of your Glowforge. It should immediately start sucking the smoke out through your exhaust close the Glowforge up, let it run for a while and see if you smell the incense in the room. If you do, it means there’s some sort of a leak between your external fan and the window.

If you pass that test, next step depends on whether or not you’re running the internal exhaust fan in your glowforge. If you’re still running the internal fan, then the best test is actually something kind of unconventional and would require disabling your safety interlock. You want to be able to run the Glowforge with the door open… Then once it’s running, do the incense test by lighting incense on the bed of your machine. This will prevent a buildup of pressure inside the machine from your intake fan. Let the exhaust fan run with the external fan… If you have both positive pressure between your Glowforge exhaust fan and the external fan and a leak between the two, you would start to smell incense at this point.

If you pass all three of those things then you know the problem is that your internal fan is making too much pressure inside the Glowforge and you’re starting to see leakage from the cracks in your machine. At this point you have to figure out why your airflow isn’t adequate even though you have two exhaust fans running.

Anyway this seems like a fair amount of work, but if you’re very sensitive and really need to make sure this you’re set up is perfect, this is how you’d do it.