Hi all. I searched for this issue but didn’t find it. My GF alerted me to clean my air assist fan. So I took that off, but of course, broke a carriage wheel (the wheel that holds the right-hand side of the belt) and luckily had a replacement. I replaced and it’s not been working correctly since. Mostly the circles aren’t perfectly circly. They are off by a tad. They seem flat on the left side and right side mostly. I have adjusted the tension and looked to ensure the wheels look correct and the belt has all the teeth. What I notice when playing with the motion when it’s turned off is that it glides no problem to the right but it’s much more stiff and jumpy going to the left, which to me seems to be the issue. But I can’t figure out how to correct it. Anyone?

Make sure that the carriage plate belt is properly installed - teeth facing in and no twists. You can visualize the belt with a mirror on the floor of the Glowforge and inspect the movement as you glide the printhead left and right. Also, consider adjusting the belt tension: https://support.glowforge.com/hc/en-us/articles/4401913883547-Print-is-Distorted

Yep, this is all correct. Have made about a dozen adjustments. None of them make a smoother movement to the left. Its still tight and jumpy. Thanks for the article. Will take a look.

It’s a pain, but I would suggest going back to the new wheel and see if it’s catching on its rotation. If yes, some lubrication might be needed.

I detect a clue there. Did you get the new wheel from Glowforge? Is the belt properly tightened?

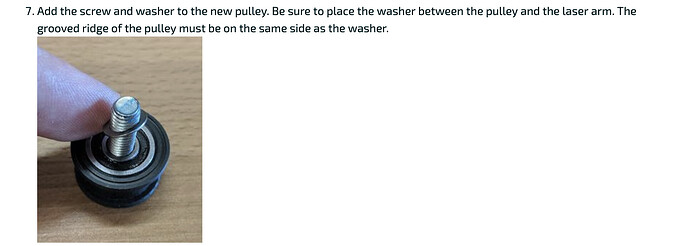

It is a GF wheel. Tightened yes. Yes in the sense that the other side of the belt moves very little when I push the opposite side. But it would be nice if there was a better way to know if it was the correct tension. The only thing I can think of is the wheel seems to have a slightly bigger lip on one side of it. Does it matter where that lip is?

I have never lubricated my GF. What brand/type is recommended?

To my knowledge, lubrication is not recommended by Glowforge in any of their support documents.

Are you certain that you properly replaced the washer at the time that you replaced the pulley wheel?

Sluggish movement of the carriage plate, in one direction, suggests an issue with carriage plate alignment, possibly a cracked or dirty wheel allowing the carriage plate to shift slightly to one direction as it travels, causing it to bind and slow movement. Inspect the four wheels on the carriage plate assembly, clean all of the interior surfaces of the ‘V’ surface of the wheels, and make sure that none of them are cracked.

I know nothing of a washer. There isn’t one there. Could that be the issue?

I’ve replaced this wheel a few times with no knowledge of a washer. So that must mean if it existed on my machine it hasn’t been around for many many months. Could this still be the issue?

Yes, this could certainly be the issue. The washer and the fact that the wheel must face a certain way. The Glowforge instructions are pretty clear on this matter.

The wheel has the skinnier end down, smaller lip. I just cleaned everything and it still cuts the same. Washer is getting narrowed down. Think this is something a hardware store would have?

Maybe.

Worth a try.

I would think that ought to work. just make sure it isn’t “binding” up. you want the washer to be pressing on the part of the bearing in the wheel that is closest to the shaft, in other words the inner race of the bearing. that washer might rub against the outer race, or the cover. hard to say.

at any rate that would be my concern. you might need to get a smaller washer the thickness of the washer could e an issue too!

Looking at the two photos I would expect the larger washer not to work as the regular one is much narrower and affects only that inner shaft. I would contact support to get the details of that washer or iuf they can send you some.

That washer didn’t do anything to help things. The sounds were different but still not right. I’m in contact with a GF staffer on the discord side.

The washer in your picture wouldn’t work because the outside diameter is too large. The washer needs only to contact the exposed surface of the inner bearing race. ACE Hardware typically stocks washers of the correct size and thickness (0.75-1.0mm). I would suggest that you take the screw with you and ask for help locating one in their specialty hardware selection.

A washer that size presents conditions similar to not having a washer at all.

This topic was automatically closed after 30 days. New replies are no longer allowed.