I am having to clean my lenses between each cut not to get it to cut all the way through.

Have you cleaned your air assist fan under the gantry recently? if not it may be having some issues.

I’d say either you are cutting some nasty stuff that is not being exhausted correctly, or there is something else wrong. I don’t do a lot of heavy engraving, mainly cuts, but I don’t clean my lens that often. I wonder what is wrong. @primal_healer has some good advice there.

Really. My GF is going on 2 years old. Admittedly I don’t run it every day. But still, I have cleaned it once in all that time. And I’ve done dozens and dozens of cuts of woods and plastics and foam, and engraving of woods and plastics and slate.

The laser should have enough power margin to cut well even after the optics have gotten a bit dirty. So the problem is likely either than the laser is down on power, or there is something in the beam path that you haven’t actually ever cleaned and that’s where most of the laser power is being lost.

FWIW, I clean a lot more than Randy - if the optics start getting dirty, it stops cutting through properly. But every cut is too much. Glad you asked here… hopefully someone will help you figure it out!

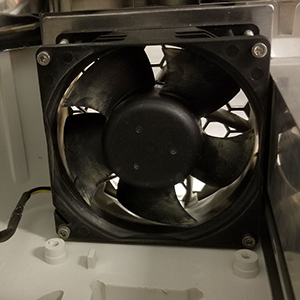

So it most likely is one of the fans somewhere:

- In the print head itself

- At the back of the print carriage

- The main exhaust fan at the back of the GF

I clean mine daily, I use a lot of draftboard/MDF which I think is particularly mucky/

For everyone I recommend checking the lens daily because muck on the lens can cause severe heating and damage to the optical coating.

I check the window under the left side on the gantry, since it is in the exhaust path of the smoke it is the first to show accumulation. When I can see any deposit I clean both windows, the lid camera, and check the lens. The lens on mine only needs cleaning about every fith time I clean the windows. The mirror even less.

After the optics I also use the wipe to clean the rails before I toss it.

Of course, your cleaning schedule will depend on what materials you use and how often you use the machine, but that window on the gantry is my guage of when I need to clean the optics.

Hmmm… that would be a good indicator. I got a new exhaust fan setup. so it might take longer for it to show accumulation. but I will certainly keep an eye on that window as a leading indicator.

I’m sorry that you’ve run into trouble with your unit needing to be cleaned more frequently. May we have a bit more information about the material that you’ve been printing on, along with photos of some of your recent prints? Also, I’d like to inspect your unit’s exhaust system to check for anything unusual.

Specifically, please include pictures of the following:

-

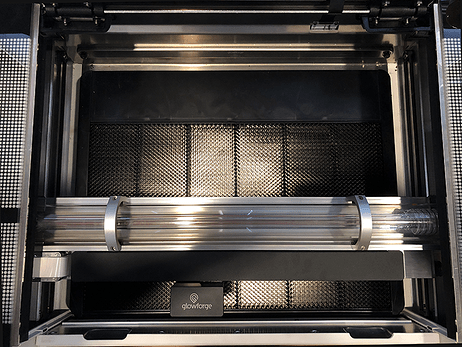

The exhaust fan from the inside of the unit. To capture this photo:

-

Turn your Glowforge off

-

Open the lid

-

Using both hands, gently pull the printer arm towards you as shown below:

-

Move your phone or camera inside the Glowforge on the left-hand side, past the metal rail, pointed away from you towards the exhaust hose, to capture a photo like the one below:

-

A photo of where your exhaust hose attaches to the Glowforge, where your exhaust hose exits the room, and the path your exhaust hose takes from your Glowforge to the exterior vent or Compact Filter

-

The exhaust connection on the back of your Glowforge, with the exhaust hose removed:

Once we have information about the material you’re using along with photos of your exhaust system, we’ll review everything and then follow up with next steps.

It’s been a little while since I’ve seen any replies on this thread so I’m going to close it. If you still need help with this please either start a new thread or email support@glowforge.com.