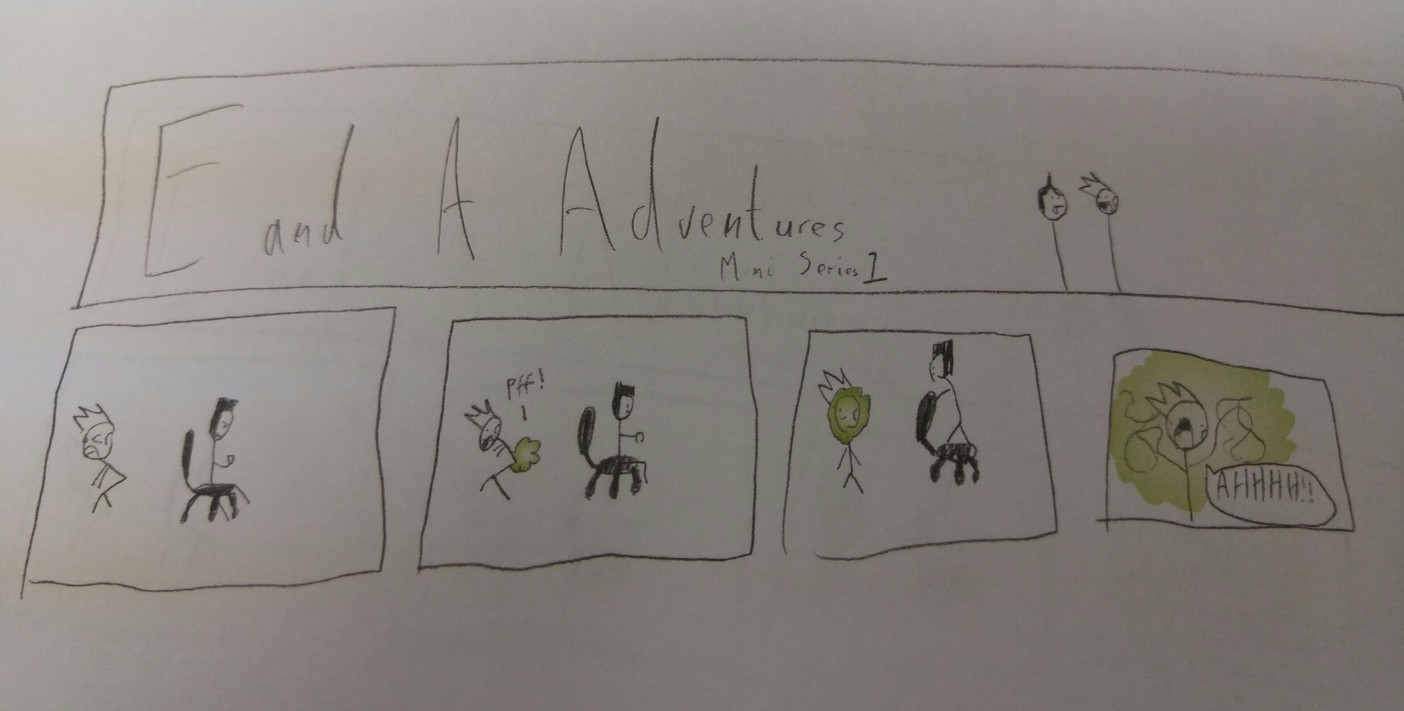

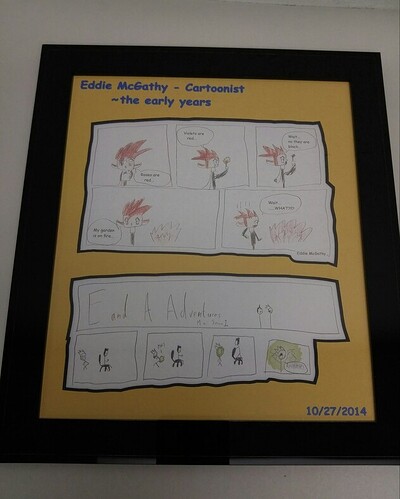

Had some time to play this evening…been wanting to frame my youngest son’s artwork he did a few years ago and got inspired…

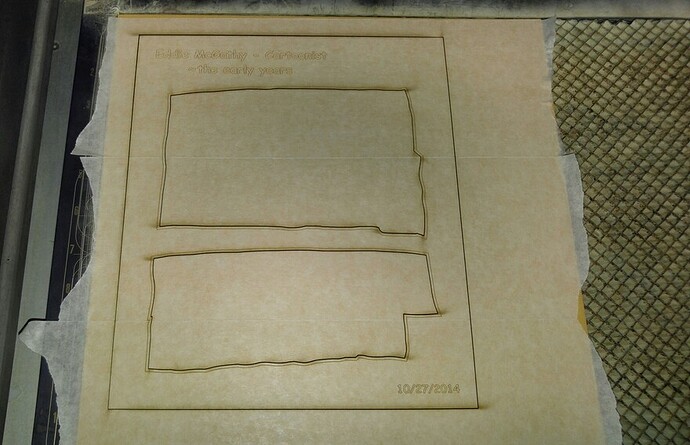

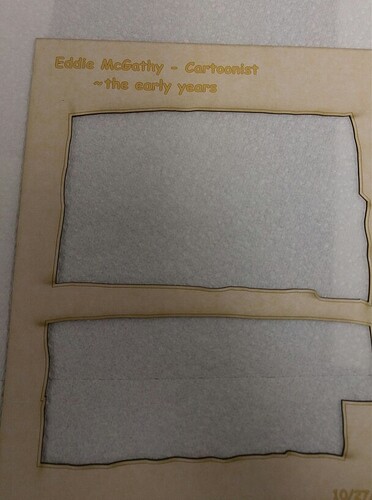

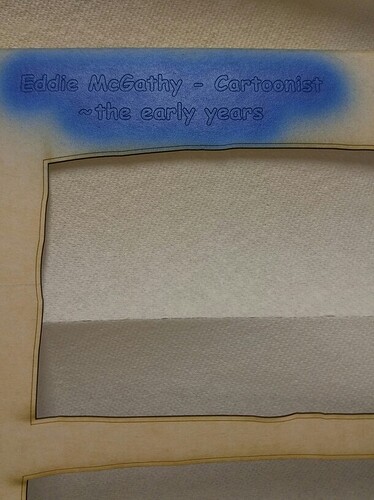

Masked and cut the mat board to fit, as well as vector engraved the words and border around the cuts and just removed the letters and thin strip of masking around the inside cuts so I could color them with the airbrush.

Removed the masking and laid over a piece of clear mylar.

And taking the cue from @dan I made a black acrylic frame to fit. Backed with MDF