If I understand what you are asking about here, it’s the normal result of the shape of the cut profile with a surface focal point.

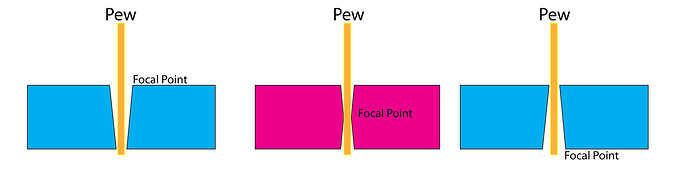

A laser that is focused at the surface of the material does not cut (or burn in this case) straight up and down because it burns a little bit less farther away from the focal point, than it does right at the focal point. It’s an intensity and focus thing. So a side view of the cut edge looks like this at different focal points inside the material:

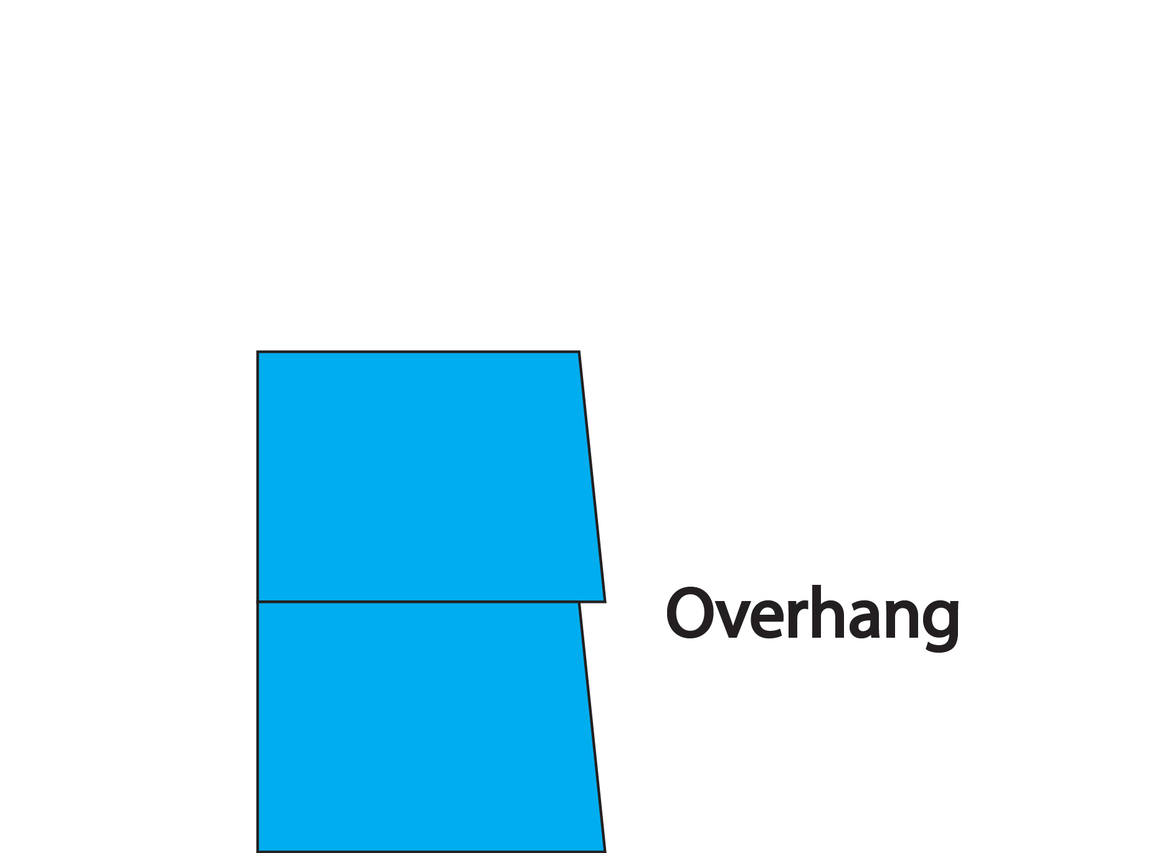

And if you stack two surface cut shapes on top of each other you get this:

The thicker the material, the more exaggerated the effect will be. If you flip the top one, yes they will line up perfectly, they were both cut at the same angle.

I’ve done some experimenting with using a center of material focal point - you still need to sand it down, it creates ripples in side stacked material.

Just the nature of the beast…might be worth experimenting with flipping it over in the hole and cutting a second time at a lower power to just burn off that edge. Haven’t tried it yet myself, but it seems like it would work in theory. ![]()

(Just looked at your file - the circles are fine. If you are actually experiencing a distorted shape, the issue might be mechanical. If the circles are rotating smoothly in the holes they were cut out of, it’s not mechanical, and you might be experiencing some degree of overhang, depending on whether you are trying to line the circles up at one side…the effect will be doubled.)