I’m a bit confused cuz I’ve used a different plank from the same lot and it’s burning badly. I don’t think it’s the material, I think it’s the machine cuz I’ve used a sheet from this lot few days back and it was very good. The machine is making a funny noise too now. I’m gonna try using a proofgrade and see what happens

Hi

I have tried the proofgrade just to see if it’s my machine or the material and yes your right it’s the material causing the problem however I was using 4mm plywood for which I had to put the speed setting down to 135 cuz it wasn’t cutting through. Could it be causing fire cuz of the slow speed? If yes then what could the solution be as I can’t use this material otherwise.

Actually just realised it was causing a little fire over the label part, that’s all I had left to try on. And the cuz was quite dark

Yes, the slower speed causes more of a flame and more charring. Be sure to check the speeds you are using every time you change material…cutting it too slowly will definitely cause flameup, and the software tends to retain our settings now. (ALWAYS check the settings when you switch between materials. You don’t want a fire to get away from you.)

Yeah, it’s likely not the material so much as the settings you’re working with. Sure, plywoods will give you mixed results, but if you’re burning sheets of things, it’s your settings. You can’t rely on proofgrade settings for non-proofgrade materials. Test your settings on a small piece of the material first. You want the right combo of speed and power that they just cut through (or etch). Also keep in mind that you sometimes it’s better to do two passes at lower power/higher speed than one pass that burns everything.

Also make sure you’re entering the exact thickness of your material.

Looks like a pretty design… hope you’re able to figure it out!

Oh right, will need to play around with the setting to get it right then

Thanks. I never thought of trying more passes on a faster speed… will have to try that. Thank you for mentioning. Will let you know how it turns out.

Check all of the mirrors and make sure they’re clean. Don’t forget the hidden one up in the left side.

Oh really, I’ve missed something out here… I didn’t know about the mirrors  . Only been cleaning the camera and glass.

. Only been cleaning the camera and glass.

Just checked for mirrors can only see 2 by the camera really

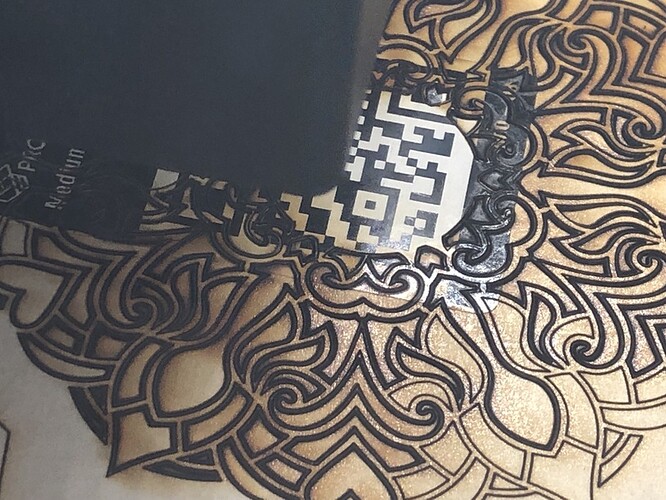

Oh no after about 2 hours of cutting I ended up with this

I had the speed much lower at 190 and I cut through twice but it hadn’t cut through so I cut again but ended up with this ![]() . The wood vinyl is just so the wood stays clean, that’s not causing the fire cuz it was happening without it too.

. The wood vinyl is just so the wood stays clean, that’s not causing the fire cuz it was happening without it too.

Ugh. It’s really important to test the settings. Just do a small set of cuts until you get them dialed in. Or try something like this:

What is “wood vinyl?”

Here are the instructions for cleaning the mirrors / lenses: https://glowforge.com/support/topic/cleaning-service-and-moving/cleaning#things-that-need-wiping

I meant the sticky paper that has that wood pattern on it was just there to peel back off to keep the actual piece clean.

I will have to run tests, can’t tell if it’s just the material, machine or both. Will have to clean and do some tests.

Thanks yes I will have to give a good clean cuz this has wasted a lot of my time. Hopefully it will get sorted after this.

I use 3 passes at 170 speed (full power) to cut through 1/4" BB plywood. 135 will definitely burn.

For this last cut I did 2 passes at 190 and a final cut at 200 but it could be that my design is too intricate although it’s only just started doing this. I’ve used this same material just last week and it was fine, it’s started doing this since the past 2-3 days.

If you haven’t followed the cleaning steps I linked to up above, now’s the time.

Yeah I was pretty shocked to see all that needs doing, hopefully will get to it tomorrow… night here. But my boy was sleeping so although I didn’t want to use the gf in that state but I just had the time to get some work done so I tried the mdf in 3mm did work pretty fine but obviously I can tell now it’s definitely cleaning time so yeah tomorrow  gn

gn

Hi, this message is to all of you, I have to say thank you very much for your help and support, it was all needed and I learnt a lot. Couldn’t have done it without you and yes it was the cleaning that was the main problem. It was taking me a good few hours just for a small print but now after the clean it’s just taking a few mins  . I can see a lot of smoke coming out from beneath but I think that’s cuz the tray needs cleaning which is a harder job. Will do that somehow later. But real problem is solved thank God.

. I can see a lot of smoke coming out from beneath but I think that’s cuz the tray needs cleaning which is a harder job. Will do that somehow later. But real problem is solved thank God.

Where would one find the Baltic birch if it’s not in a Home Depot or other box store? Do you order it from somewhere? I’m realllllly struggling to find a good plywood for my projects. I would love to use only the proofgrade… but it just so darned expensive … I would really struggle to make a profit with my projects if I used the PG.