During the Q&A video Dan showed a louvered lamp. How are those louvers cut?

Everything is cut flat at 90 degrees to the wood. Notches are cut at an angle to allow the flat louvers to slip in.

The cut would look sort of like the below: (for the edges)

__

/

/

/

/

OR

___

The slats are then fit into the notches and possibly glued into place.

Bingo. Not glued, though, it’s pretty much all just tabs in slots.

I have a neat video of the lamp in sketchup I can share… it was one of the first things I made where I said to myself, “Self, this could actually be useful.”

How do you get the angled notches for the louvers to slide into? I would love to see the video. I’m trying to picture the structure in my head, and I just can’t figure a way for it to work without a known-depth partial cut or making the laser run at an angle, and I didn’t think either of those were available features yet.

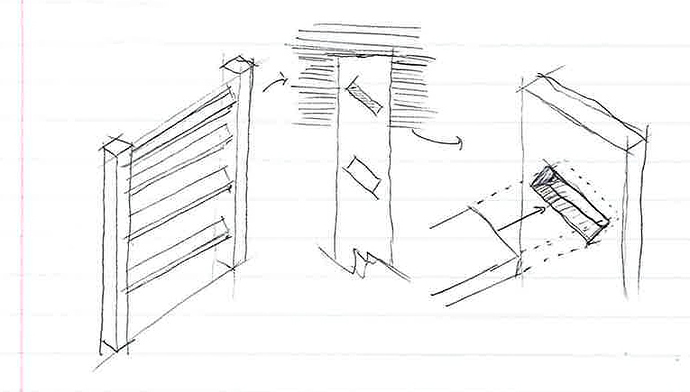

Quick sketch reply- here was my very first thought on how the louvers were achieved. Just cut rotated rectangles out of the frame of the lamp and then the louvers slot right in  I suppose you could play around with rastering the cuts instead to try for half-depth notches?

I suppose you could play around with rastering the cuts instead to try for half-depth notches?

Yes video please.

This is how I pictured the slots. But as you can see, the laser can’t do that!

@steph_ must be close but that requires the slot to go all the way through. The video was back lit so I couldn’t tell if it did that.

Rotate the piece 90 degrees. Engrave (not cut) the notches. Solved.

It’s about thinking in all the dimensions the work can be done in, and finding the ways of doing so that best fit the tool at hand.

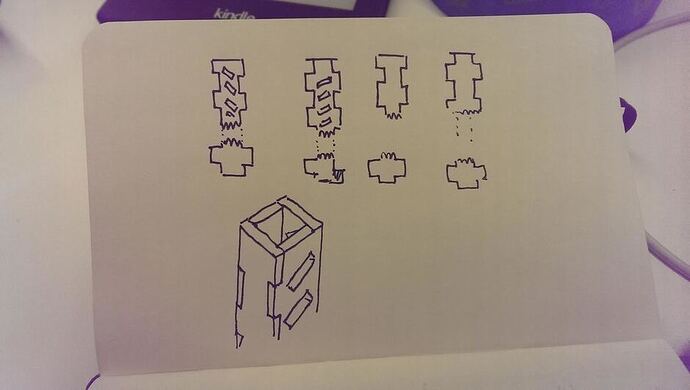

The handdrawn sketch is closer to what I did, except the tabs are shorter than the louvres so they don’t slide through the holes, and the tabs have diagonal corners to make it easier to get them in.

@dan Not sure if this was the desired result of this uploaded video … https://www.youtube.com/watch?v=E9I6jpHwJ6I

It shows 5 secs of the design process then about 5mins of B-Roll of what looks to be unedited dolly shots of the lamp?

If you pause at 1 second you can see the “dados”. As stated above the trick was engrave not cut.

I think the video was just ment to be a neat transition from a digital 3D model to a physical object.

I think I trimmed out the extra 5 min. This was a video I shot as an internal concept piece of what we might be able to build. The lamp was shot with a skateboard in my living room. It’s all very low-fi, but I thought you might enjoy the quick peek at how the lamp went together.

From the video, you can tell that @steph_

was pretty much right (though I I’m not sure if etching the grooves would work). As the vertical members on the four corners of the lamp are hollow and held together with a box joint, the grooves for the slats can be cut all the way through with the piece lying on its side. The outside pieces hide the backside of the grooves, no etching necessary.

forgive the crudeness of my drafting:

@dan, do you think etching the grooves would be a possibility? How controllable do you expect etch depth to be? Also, can a contiguous etching space be expected to be cut without starting a small fire?

Your sketch is spot on. I don’t foresee a problem with engraving.