I could use the same SVG to gen the g-code to cut them. But if you think the 1/8 acrylic has no flex, you should try aluminum or steel. I have some 11ga stainless but I’d think they’d be good in lighter gauges. My kerf is way bigger though so I’d probably need to scale them up a bit so the end result is the same size. Might be fun to cut a sheet out though. Polished to a high sheen. Not economical but fun ![]()

This is great project I got one from a friend and I love it! keep the good work.

Was half joking. Getting an edge that would not slash instead of hold would take even more work, but bent they would bend and stay bent instead of break.

Imagining a remake of .007 and the bad boy, Oddjob, uses his stainless earsavers to kill from across the room…

Easy enough using the bead blaster to put a matte finish - with a somewhat aggressive media it will gently relieve the edges. Or tumbled with walnut shells maybe.

I have been thinking even sharp sand for the wood as well as salt has not done what I wanted. Any sand from the upper point of a river, or for construction should do better than beach sand,

Oh, nooooo!

I don’t think I have enough acrylic for 1000, but I’d be happy to do a chunk of those earsavers for you if you want me to. I can go take stock of my supplies and let you know how many I can manage, unless you think it’s better just to let them be re-matched.

I’ll let you know if I don’t hear from them to the contrary. I can send you the acrylic sheets you’d need.

I could do a few 12x24 sheets, I bought 10 in dark blue from Estreet but spending a long time in peeling.

Still waiting on GF now.

But I’ll ship the acrylic so no one is having to come up with it. I pre-peeled all the sheets. I stick them on a sheet of newspaper. I had to pull the newspaper off about half of them. They’re more electrostatic than sticky.

BTW, I got my d-i-y cable kit. The spool of 500ft of flat wire is like 12" diameter. Big box with a tiny bag with the connectors buried in the shipping paper.

Now trying to decide if I should wait to hear the latest from my log analysis or if I should just go in and do it.

I would appreciate that but have close to 1000 already cut as I wanted them done before offering rather than waiting for the sheets to be delivered and then cutting, and the place where they were supposed to go has not responded after several attempts. I think that many are like this person who has no use for them himself but a large batch for free allows him to make a great show of turning up at the Hospital and delivering them but would not lift a finger or spend a dime otherwise, and by now has forgotten he even asked for them.

Getting sheets of other colors would replace the ones I cut up while waiting for these to come in’

The ones I had outstanding needed customization for UMASS Childrens. I have the project file for that and made the customization a single line font that I scored. Turned out great for the hospital in Peoria and was looking good on the UMASS ones until my machine died. I was using 1/16" 2-color extruded acrylic. It cuts well, was pretty cheap from BF Plastics and bends a little so it conforms to heads better. The gold backed 2-tone sheets take a score (engraving) well.

The nurses I’ve been getting matched to have all been super about getting these and even patiently waiting. The one from Peoria volunteered to pay for anything I needed if that would help. I asked him to pay it forward instead. He was so patient while I worked through several thousand other ones that didn’t need custom engraving. After I told him that was the cause of the delay he said he would have had me skip the customization and wished GF had made it clearer that customized ones might take longer.

It might be a race between GF re-matching (or not) UMASS and my getting my white cable made & replaced and back in business  They’ve been radio silent on this for a week now.

They’ve been radio silent on this for a week now.

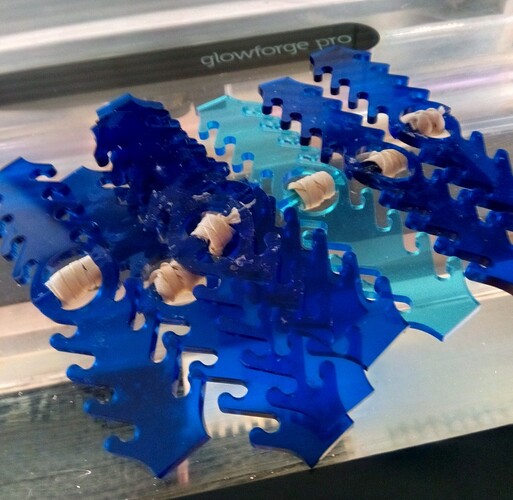

I have at least a hundred of these flexies tied with nylon lacing with a knot that finishes underneath that I added white glue as it will seal the nylon but not attach to the acrylic and so flex easily20-40 degrees from straight.

They take a while to do, but do not have enough hair ties or similar to go the easy way. All long and Flexi have no other marking as they took longer to cut, were not as strong, and a lot harder to weed (and all are weeded after cutting)

It makes me sad that we really can’t put a dent in the need with our machines and this needs a big manufacturing approach. But it’s certainly better than nothing and we’re hitting some of the people who may not otherwise get one at all.

800 done and shipping today

For perspective, going from “we should do this” to mass produced injection molded plastic parts in the US is generally a months-long process. We helped nearly a million people in the first month! A million people! That’s amazing!

The opportunity to help even more is exciting too, but doesn’t diminish the incredible accomplishment of helping one million people.

A lot more are being produced than the “official numbers” show. Many people are working directly with their community.

I saw a post about someone’s company doing 100,000 and felt bad I only did 11,000 before my Glowforge died. Up against 1M it’s a drop in the bucket.

I’ve got materials for another 10,000 so if it gets fixed before the need runs out I’ll get back to cutting otherwise I’ve got a lifetime supply of acrylic in the basement ![]()

Absolutely, it’s just the reality that we put our hand up and almost immediately had more requests than we could handle. For what we pay in health costs here in the states, millions of these basic parts are needed still? I’ve got a lot of feelings about that, sad is the most PC version.

I didn’t mean to put a negative spin on our communities impact.

I downloaded the latest file, GlowForgeEarSaversFullSheet_V3 and the cut lines are misaligned, mostly on the right side. The word ‘Glowforge’ and the accompanying pattern are completely misaligned on the right side such that they overlap with the cut lines. Many of the earsavers have to be cracked apart (which leaves a sharp corner). Is there a benefit to V3, or can I just use an earlier version that my daughter was successfully cutting with?

There is rejoicing and happiness in the nursing station today. Thank you, @rbtdanforth, for the ear savers care package!

Most welcome ![]()

What is the thoughts on the flexies?