I’m making a living hinge glasses case using Proofgrade maple plywood. It will be lined with felt to keep from scratching the eyeglasses.

Easy cutting the PG, but what settings do I use on felt? I’m using a self-adhesive craft felt from Michael’s. The stuff is 0.075" thick with a peel off liner on the back.

Into the 'forge, load up my cut line test file and start testing. My cut line test file is simply a set of 2 lines, one vertical and one horizontal. If I want to cut a piece off material I can set the GFUI to ignore one of the lines, set the length and place it where I want the cut.

In this case I used both lines as that gave me two tests for each run. I started with 100/100 (power/speed) and 100/197. 3 seconds later I knew those were too hot/slow.

Since I can’t go faster with a cut than 197 in/min, I had to start dialing down the power. I approached it with a binary search for the right setting. Each change was half the prior one. If you go too low, the next one goes back up by 50%. It makes zeroing in on the right settings pretty fast.

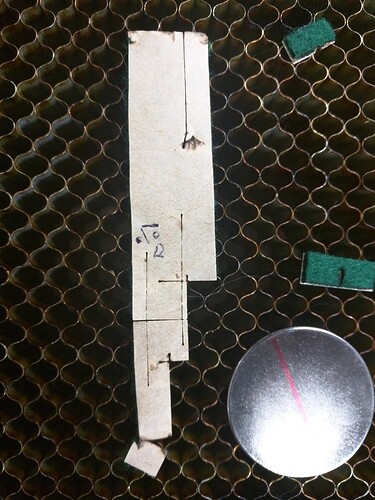

Since 100/197 cut right through and I was trying to get it to just cut the lining paper, I tried 50/197 & 25/197 next. Worked my way to 1%/197. This cuts the felt through and almost entirely through the lining paper - enough that it’s almost like the paper is perforated. At 3%/197 it’s clean through both.

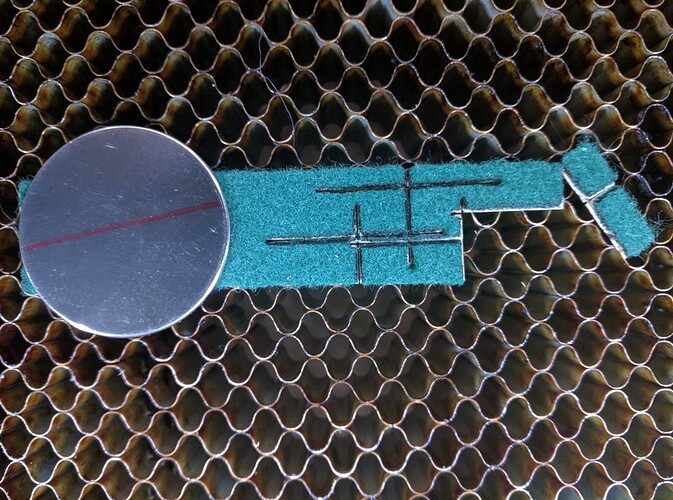

Here’s my little test piece:

The silver disk is a quarter sized 1.5mm thick neodymium magnet. A little piece of felt like this will blow away from the air assist ![]()

Here’s the back side of the last test:

Now I could cut my lining felt and work on finishing the eyeglass case. Of course I could have cut it out with an X-acto knife faster but only because I needed to find the right settings. From now on, especially for intricate cuts, the razor knife doesn’t have a chance.