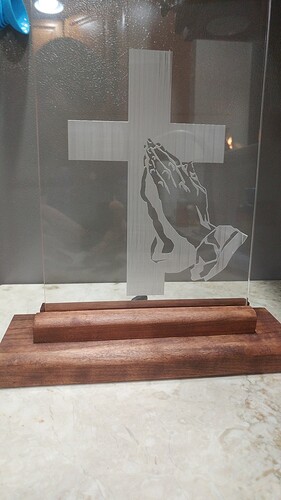

I have finally upgraded to a Glowforge Pro from a K40.

I have been making bases for edge lit acrylic with my router and table saw.

These are made from cherry, I have also done oak, walnut, cedar, and pine.

I am working on a Master’s Degree, and running a business, so I don’t have as much time to play in the shop.

I need a way to decrease production times, as these take about an hour between machine set up, calibration, and bit changes.

Any ideas are appreciated.

19 Likes

evansd2

September 13, 2020, 7:52pm

2

Hey, welcome.

Right offhand, edge lit bases are a solved problem and are very inexpensive to buy on amazon and banggood and aliexpress. If I were in your shoes, I’d be looking for commercially available bases to save that entire part of your workflow.

4 Likes

I have some of them.

These plates are 8x 10 and the pucks aren’t bright enough or stable enough for that size.

I have been reading for several days, and have yet to find what I am looking for.

I found one that was close, but needed a 3D printer.

2 Likes

Just make a box with a slot in it. (You can probably do it better than this; this was in my very early GF days!)

As promised elsewhere, here’s the box I designed to go with the USB cables and dimmable LEDs I use for edge-lit pieces.

The slot is 1.47" wide, and accommodates proofgrade medium acrylic. (It will fit the edge-lit Neil Gaiman quote I uploaded a while back.)

(Note, this was designed before I learned about kerf, so it requires gluing.)

[Small%20Light%20Box]

The small bits are to glue around the slots for the acrylic and the USB cable, to help hold them securely. The USB slot is tight and will …

2 Likes

evansd2

September 13, 2020, 10:24pm

5

“Box with a slot in it” example #2

What time is it?

[IMG_1675]

(Walnut, cast acrylic)

It’s clock time, of course.

Quick notes:

Overall base dimensions, about 14" wide, 3" deep and 1" tall.

Base sanded to 600 grit and finished with wipe on satin polyurethane.

Letters about 0.35" wide.

Overall height of the acrylic is 5.6".

Addressable WS2812B RGB LEDs (60/m) driven by an Arduino nano clone with a DS3231 clock unit.

I wanted the text to be center stage so I intentionally went simple on the base. To that end, I wanted to…

Though I will say that boxes are labor. Find a base that can work and modify your design to match it if need be.

Look for sign bases not just small pucks. They’re bright and minimal.

3 Likes

Thank you, I appreciate your assistance. Nice clock,btw.

1 Like

I really like my 3D printer for making bases, especially if you get a translucent filament. I think I had a pretty good workflow to manufacture my own with little cost. I especially like that I can print a full bed of the PLA sides overnight throughout the week and when I have time to assemble, I have plenty.

The most time is engraving the acrylic, but if you have a good design and do a score, it can work ok.

[IMG_0537]

A boy scout has chosen to put in a new playground on the church campus for his eagle scout project. It entails lots of brush clearing, digging, concrete work, mulch spreading and other physical labor. Included in the project is securing funding. I thought that we could make some edge lit acrylic signs and sell them to raise funds. We put out 100 order sheets and they were gone in two weeks, plus some more that we added on, plus a few custom designs. I have a massive supply of 1/4" ca…

2 Likes

I read that post, it is an elegant solution.

I honestly don’t have the time, money, or space to get into 3D printing.

1 Like

eflyguy

September 14, 2020, 8:33am

10

This is the widest I’ve seen.

What you’re looking for is pretty unique. If you can’t produce it yourself, you could use any of the 3D printing services.

ekla

September 14, 2020, 3:19pm

11

Are you making just one base at a time?

1 Like

I was going to recommend the same thing. Batching things out helps a ton

1 Like