I noticed that relatively recently, my engraves have started to get a kind of double-vision effect happening on the X. Any help would be appreciated…

Closely inspect your belts for proper tension. Also look for any cracks in your wheels.

I checked the belt tension and it looks ok. I placed my phone’s front facing camera underneath and when I press either side of the belt in, the other side doesn’t show signs of slack.

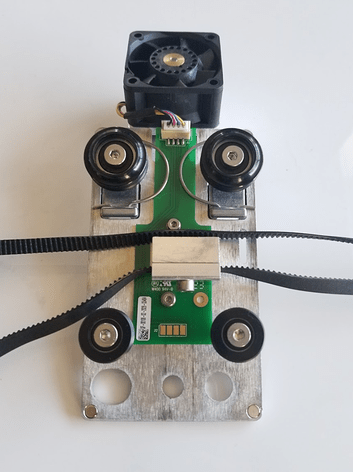

I’ve checked the wheels on the front part of the carriage under the laser head, but there are no cracks. The carriage and belt are actually new since I replaced them maybe a year ago… this new belt is thicker than my old one so when I created tension and screwed it back into place, the belt can’t come off track like it used to before… so I really hope I don’t have to take the carriage and belt off again, because it’s a HUGE headache to do so…

Here you can see the spindle on the right side… I had to push it ALL the way to the side to get the tension right.

so now there’s no room to get the belt off the spindle without loosening it again.

If this jittery engrave is new, then something changed to cause it. Check for debris on the rails and in the belts.

Well I’ve checked what belts I could before and didn’t find anything. It’s not that it’s jittery, it’s just doubled and only on the X-axis. I can’t say when it started, but it is relatively new since I’ve been laser cutting stuff for the holidays all month.

Have you looked carefully that you did not copy the file? It looks like it is doing the same thing twice.

It’s the “Gift of Good Measure”… pretty sure the artwork isn’t duplicated. =) But other stuff that I cut regularly was getting the double-vision treatment too where they were totally fine before and I’m positive those aren’t duplicated.

This is the official troubleshooting guide for this issue:

It’s almost assuredly going to be a belt, wheel or tensioner pulley at fault.

The guides also contain an animated GIF that shows what tension to target:

Taking the carriage plate off to clean the air assist fan is something that needs doing semi-regularly, so it’s best to become comfortable with doing it.

No good. There’s no debris in the belts I can find, the tension when pushing on the belts matches the GIFs, and to be absolutely sure, I grabbed a single vertical stroke, outlined it into a shape and brought it in for a test engrave…

This was the result… clearly double.

I know you checked for debris and I trust that if you didn’t find any then there likely isn’t any. From your pictures it looks like you do a lot of cutting and there is a bit of residue. Have you tried cleaning your belts? You might have buildup as opposed to debris.

It goes into detail on that towards the bottom of that ‘Print is Distorted’ page.

Hi @pauljima My name is Mercedes and I’m part of the Technical team here at Glowforge.

The forum folks seem to be on the right path here with this one. Can I get a couple more photos of your belts though?

In order to take a closer look at this for you, would you please send me the following photos?

First, power off your Glowforge and remove the crumb tray.

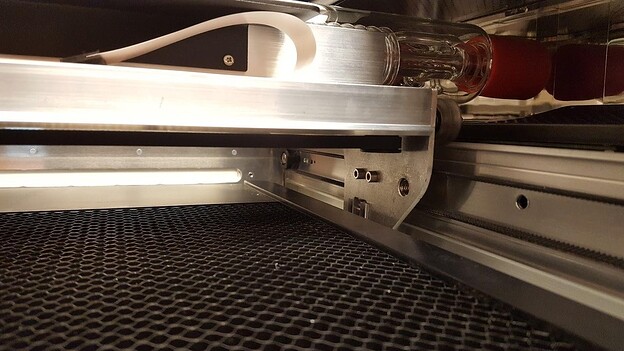

1.The belt under your laser arm with the head pushed to the left:

2. The pulley under the laser arm on the right side from the front:

3. The right side pulley under the laser arm from underneath:

This will help me get a better view of what your belts look like.

Hi, thanks for helping out. Here are those shots…

I also recently cleaned my fan assist and made sure the spindles on the front and back don’t have any cracks or anything.

Thank you so much for those photos. I would like to check the carriage plate wheels to make sure there is no damage to them.

Could you please do the following?

Turn off your Glowforge

Closely inspect the carriage plate wheels from the top for any cracks or other damage

Closely inspect the sides of the wheels for any cracks or other damage

If you notice anything damaged or out of place, please take a photo and attach it to your reply.

I’ve checked all 4 spindles and can’t find anything wrong with them. Do you need me to post pics anyway?

Thank you for those photos I would like to follow up with you over email with the next steps.

Much appreciated, thanks!

Just checking in… I got an email last week which I replied to but haven’t heard back since.