You know that feeling when you return home after a long trip? That mixture of comfort, excitement, and “finally!” wrapped into one? That’s exactly how I’m feeling today – both literally, as I just got home from an amazing trip with my family, and metaphorically, as I share the latest news about what’s happening at Glowforge.

As I shared last month, it’s now been ten years since we started with a dream and a crowdfunding campaign that broke records. It reminded me of why we started Glowforge in the first place: to transform how things are made. I’m excited to share two huge transformations that reflect that mission - both in how we make your Glowforge, and how you make amazing things with it.

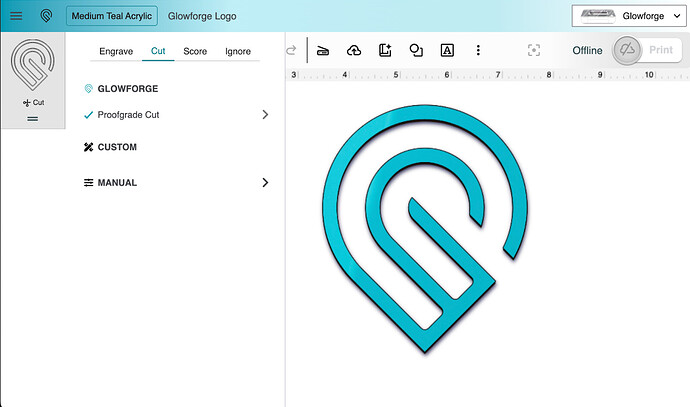

A Fresh New Look for Your Creative Canvas

After a decade of adding more features to the old workspace, we asked ourselves - how do we ensure we are ready to keep growing from here? Can we make every feature more discoverable, every action more intuitive, and every creative session more fluid? What if we could build something that works beautifully for both first-time makers and seasoned pros?

After months of work and testing, we have excitedly begun to roll out a fresh new look and layout for the Glowforge app! You should see it when you open your workspace in the coming weeks. Whether you’re crafting your first design or your ten thousandth, you’ll find a workspace that’s ready to bring your ideas to life faster and more intuitively than ever.

Made in the USA

I wanted to share some exciting news from Glowforge, where we’ve just achieved a significant milestone in American manufacturing innovation. With the help of some transformative AI innovations, we’re moving from our production factory in Mexico to a high-tech, high-efficiency manufacturing operation at our headquarters in Seattle.

This isn’t just about changing an address on a shipping label. We’ve developed breakthrough AI-powered vision and process-control systems that let us do something remarkable: create a manufacturing process that’s more efficient, more precise, and more innovative than traditional approaches - a move that lets us pay local workers strong salaries while still keeping total costs less than what we paid in Mexico. It opens a door to a more resilient American manufacturing model, one that actually benefits from advanced tech and a skilled local workforce, elevating the human-side of manufacturing too by creating new jobs, skill sets, and operational safeguards that weren’t possible even a few years ago.

I’m proud to say that this year, all Performance Series lasers we make will proudly be made and serviced in the USA.

Why These Changes Matter

Both of these transformations share a common thread: we’re combining human creativity with technological innovation to make our tools be more efficient, stronger for the future, and therefore more magical.

I can’t wait to see what you’ll make with these improvements. Your feedback helps shape everything we do, and I’m excited to hear what you think about this next chapter in the Glowforge story.

Creating the future together,

– dan

PS: You can discuss this update here.