I’ve seen the real deal veneer and do want to try it out, but thought it might be nice to have both in play, with the real stuff used more for accents.

beautiful job. I like the turtle best but both are fantastic looking.

Very nice work!!

Nice use of A.I., and the results are really great.

Stunning

Excellent execution. So fine and fit.

Thank you so much for taking the time to write up your process. These are amazing, and I’m in love with the turtle.

looks very nice! good work!

These turned out great! Thank you for sharing your process!

Those are beautiful. Thanks for sharing your process!

Many thanks for writing up the details of your workflow’ very useful. I especially like how the turtle came out.

Thanks so much for a great write-up on this! I’ve not tried to do inlays before.

Would you mind sharing your etch settings for power/speed? I realize that materials may differ, but it would be great to have a starting point to test with.

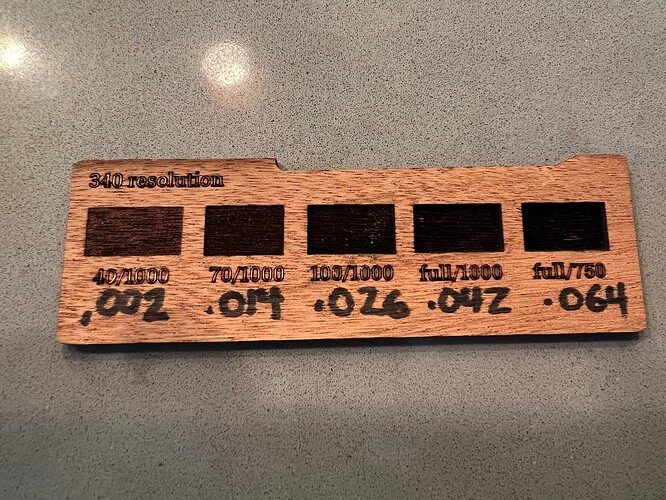

Depth is HIGHLY dependent on material so you will need to conduct your own tests, but here is a test on mahogany. 340 resolution, Power/speed. Hand written number is depth in thousandths of an inch:

Matt

Thanks so much, Matt! Now it’s off to the laser to try my luck. Really appreciate what you’ve done here!

There’s a great little engrave test layout here:

Thank you! I’ll check it out.

Those are VERY nice! Did you need to make any adjustments to inlay size vs cutting board engraving to account for laser width? I tried an acrylic inlay in wood (very fine detail) and the acrylic is loose in the cutout. ![]()

Hey, welcome to the forum!

Fyi this is known as “kerf adjustment”, you can find lots of threads here about how to do it.

The only kerf adjustment I made was flipping the inlay over and cutting a mirror image of it because otherwise it was too tight. Sounds like you are having the opposite problem. Kerf will vary with the material, cutting speed, etc.

I havs found that the hole made by engraving is smaller than the one made by cutting, so when a cut piece is put into an engraved hole the result has been very tight. Especially if the hole is deep and the cut piece is 1/8 thick.