It came to my attention tonight that a certain facet of bending things has not been discussed here so I thought we’d discuss it very briefly and I’d drop a few URLs for further reading.

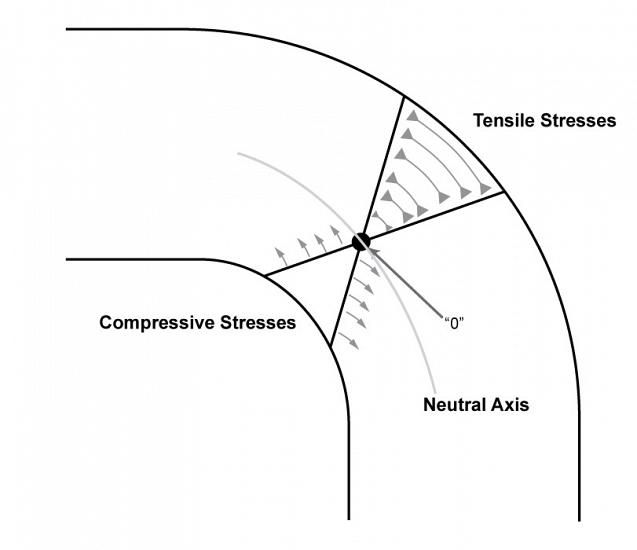

Whenever anything is bent two things happen. One, the outer radius is stretched, and two, the inner radius is compressed. If the inner and outer stretched the same amount as the inner compressed, the maths would be super simple and for things that tend to be forgiving the simple will usually work. For other things, you might cut and then bend it is a bit more complicated.

Living hinges should be forgiving enough most of the time to ignore this, leather would be the same.

Get into plastics such as acrylic, now you are going to have t consider K factor.

What is K factor? Well, all it is is a multiplier that compensates for the fact that materials don’t always bend right down their center, in fact, they rarely do.

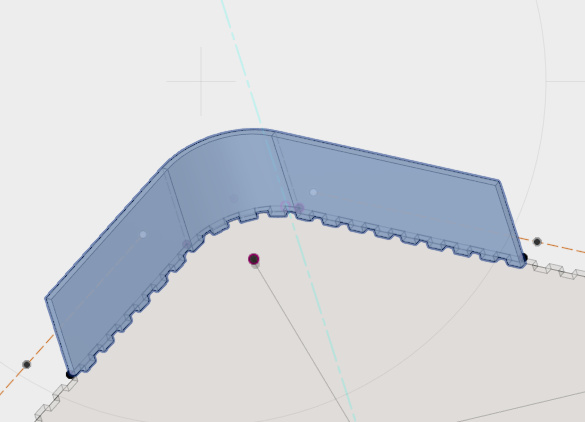

I had to learn to calculate bend allowances by hand but great news, Autodesk just added a sheet-metal module to Fusion 360 so learn that and all the maths will be taken care of for you. I would be beneficial to read through some though so you will understand what all is being compensated for.

For most metals, there is a published K factor but for the things we work with it will be hit and miss. Try google for finding a starting point but like kerf, you may well have to find it through experimenting with a material.

Go here for general understanding:

https://www.engineersedge.com/sheet_metal_calc.htm

https://www.hawkridgesys.com/blog/sheet-metal-understanding-k-factor/

Go here for plastic:

These are just starters. Read as much as you want/need. Knowing that it exists is the larger part of getting where you want to be.