At the 53:15 mark

Thanks for the spoiler. I’m 30 mins into the podcast then decided to check the forum…

Oh haha! Sorry!! I won’t say anyhing else.

“salt in the wound of thousands of people” Ouch.

Awesome to hear how someone experienced with laser cutting technology, and access to other models is still excited and loving a machine that is still going to get better. Makes me excited for the early Christmas in 2017 when mine will finally arrive.

They still have a week left to get in my top product of the year slot!

Wow, declaring it before the year has even started. That’s bold!

Ok all caught up. My favorite of 2016.

Movie - Captain America: Civil War

TV - The Expanse

Product - Nikon D5500

adding tool category cause that’s who we are…

Tool - Digital Protractor

Funny. You hear ‘salt in the wound’, I hear Norm saying with enthusiasm that he really loves using the Glowforge even though it’s not yet a completed product. Can’t wait.

Yeah, this guy sees ideas/gadgets/tech come and go. His endorsement carries weight.

I assume it is “salt in the wound” because Norm likes it already but apart from he and two others we all have to wait at least 7 months.

Yeah, that was clear, just kidding a little. The other guys’ statements were to be expected given that the unit is not yet in production. But I was truly surprised that Norm was that enthusiastic. Expected him to say something like the Glowforge has the potential to be a great product, but he jumped right in to saying he loves using the unit even though it is not yet fully capable.

Yes, as I said in another thread, it seems to have got to the stage of being a very good basic laser cutter at a good price on pre-order. I.e. the form factor, ease of use, integral cooling, etc. But most of the revolutionary features seem a long way off.

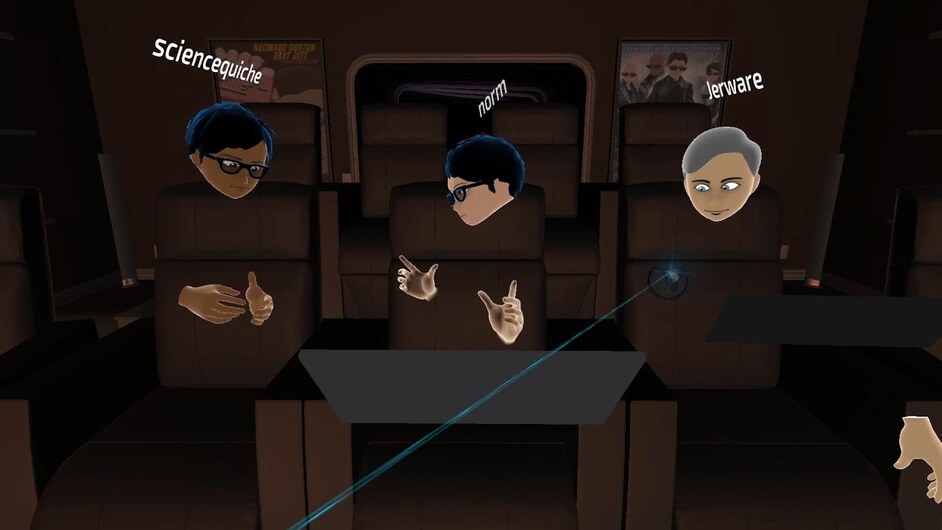

My thoughts exactly. He’s usually a bit more on the cautious/calulated side. ![]()

He meant of the decade!

Yep salt in the wound norm .salt in the wound oh how it burns!

So. This is a desktop laser. With the filter it will sit there not taking up much space compared with all the other things needed for a 40 watt laser. So it can be an office fixture rather than a workshop fixture and look pretty cool. The air assist and the exhaust just work and I don’t have to think about it. Cooling? You mean these things have to be cooled?

Granted, I have not tried to engrave a full sheet of material in one print so I don’t know the cooling off requirements. But this is a fine piece of machinery.

Most laser cutters need a chiller to cool them. Some people get by with a bucket of water if they don’t run it for long, or a radiator and fans. Glowforge is the only one I have seen that doesn’t need external cooling, other than big industrial ones that have room for a chiller inside.

CO2 lasers are only about 20% efficient, so for 40W out you need to put 200W in. 160W will heat the tube and 40W the work piece. You don’t want to allow the tube to get much above ambient, so getting rid of 160W with only a few degrees rise in a small space is not easy.

Ha! Yeah I have a sealed bucket of water. Works well enough

I get the impression that aluminum and ceramic tubes are typically air-cooled. I also get the impression that these kinds of tubes are a big reason Epilog, Trotec, and Universal engravers (and prolly others) cost so much.

My lil’ 30 watt Trotec is air-cooled.

Yes the metal ones are RF excited and cost about 10 times more than glass DC ones. I don’t think they are any more efficient, probably less, but I imagine it is easier to get the heat out with aluminium.