I am trying to discern if my laser tube is in need of replacing or what. Got the glowforge in Aug of 2020. It has worked well for us and used it a lot not as much as some here keep it going 24/7. But a lot. Lately… normal cuts i always do have been requiring two passes. i.e. it cuts through the board where it should on some parts of the board (closer tot he right side of the glow forge) and does less well cutting through nearer to the left side (which to me is closer to the first bounce of laser mirror). In either case, is it my laser lenses? I do clean them but are they getting bad? Is it the tube? Again lenses are cleaned using wipes and all but issue persists. Curious what other trouble shooting things to try in hopes of it not needing a new tube (many successful cuts until lately).

I had my glowforge basic since January 2019 (i think). I used it more than a basic should be run, nonstop for over 4 years. All cutting issues had been dirty lens, mirrors, air assist fan in the print head, or a dirty exhause fan/exhaust port.

The clogged exhaust area was a real issue for me. I had removed the fan because i used an external fan, but because i have pets, all the floating fur would block the air intake at the front right (when looking at the machine, throwing an overheating warning from lack of air flowing in) and create an unseen net in the back that blocked smoke from escaping and interfering with the laser beam.

All issues required me to clean regularly, and as long as i stayed on top of it, i never had an issue cutting through unless it was the material.

Hopefully it’s not the tube for you, but timeline wise, i suppose alot of us are past due for a tube replacement.

I did just clean air assist fan and not long before did a full clean of glowforge. There is an odd ‘whirr’ from my inline fan I haven’t heard before, I think gunk from exit fan of glowforge got into air assist fan? …it is just strange. I would say the hours for this 3 year old glowforge is less than many. It was also all of a sudden it would not cut through without doing two passes. Long after I did the full clean of the glowforge, long after I did a lens cleaning. Etc Was just curious if there was quick ways I could test without wasting a ton of wood on projects

Also yah, I guess tube replacement is long over due. I am sad they dont sell the basic anymore and sadder still I dont know the costs involved in sending mine off to get it up to snuff.

I think the last few tube replacements i saw people talking about ended up being refurbs purchases instead of a tube replacement on the existing machine, but don’t quote me on it, i don’t pay as much attention as i should.

On my pro, the exhaust fan, which is still in place, is gunked up. I was using an external fan, but the buildup on the exhaust fan was preventing air flow. When i actually use the exhaust fan, it makes an awful sound because it can’t spin properly. But its too hard to clean with that cooling thing in the way.

Your external fan doesn’t need cleaning does it? I used to cut massive amounts of mdf…lots of fan and optics cleaning every day.

I’ve read several times on here that if it’s the tube, it just begins diminishing very slowly…not suddenly, so that may likely omit that as the problem. My basic is over 6 years old now and seems to be going along just great.

There are no blemishes on the two windows, the head mirror or the lens? I believe support can tweak the power on your machine, perhaps that may help.

Did you also clean the lens on the inside left wall of the Glowforge? It’s often overlooked, and I hear that can be the cause of it cutting poorly on the left vs. the right side.

ya what @Purplie said. I had some smoke residue build up on mine. at one point.

.

Normally. it ir the right side that is weaker when that is the problem. I have no idea what would cause the left side to be weaker. The exit fan is the last the air sees so maybe it is just all backwards.

The suggested quick test is to run the Gift of Good Measure on proofgrade using PG settings. That will remove any question of design issues or user errors.

Pictures of all 6 mirrors/windows/lenses would allow us (or support) to be a 2nd set of eyes.

Yah I generally clean the window to the left, and the lens inside the print head. Normally I never touch the other lens inside the print head that is angled. It does cut better on the right side than the left side actually so that is strange too. Top of the board cuts are fine just do not go all the way through in areas of the cut on the back side. I don’t have proofgrade but was going to run a few more cuts. I first noticed it when trying to cut 1/4" walnut plywood and then again cutting 1/8" cherry wood too. After I cleaned the windows. Also i did clean the air assist fan a while ago, thought maybe I jacked the belt tension up putting that back on? But this issue doesn’t feel like a belt tension issue.

Just did another cut. Made sure all lenses were clean. Ran a proof grade thick walnut cut on a board from homedepot I have cut many many many times before. Result was, cut all the way through left of glowforge, top, and top right, not the bottom right. Out of ideas, how do you tell support to boost the power? This is so strange.

Bottom right only is 90% of the time that the mirror under the left edge is dirty/damaged, or misfocused. Most of the time misfocused is discovered upon first receiving the laser, so unless you were under there banging around that’s unlikely.

Yah I did give it a pretty good clean of that air assist fan and also did do the lid , and sucked out the exhaust on the back end with a vaccum so that is all I did, and it worked fine after that it was quite a few weeks ago. So now, not sure I even cleaned the inside the head angled mirror too and same issue. I did just think I have cleaned the main lens but not really wipe down the other two tiny lenses on the print head…maybe I should give those a wipe down (they don’t look dirty though).

Any time there is a difficulty in cutring through on the right (and not an issue with the material) it will be the same cause, The window under the left is not clean.

This is not a case of slow buildup but an instant situation when smoke is lying against the window as the laser is being fired, thus frying the bit of smoke to the window. The amount may be tiny, and it certainly gets worse over time. But the slightest blurring will cause less power to be delivered on the right side vs the left.

Any time I see the issue I clean that window. There have been times when I could not even see the problem, but the Ziess wipe comes up with a light brown stain, and the problem is solved so I know it was the issue.

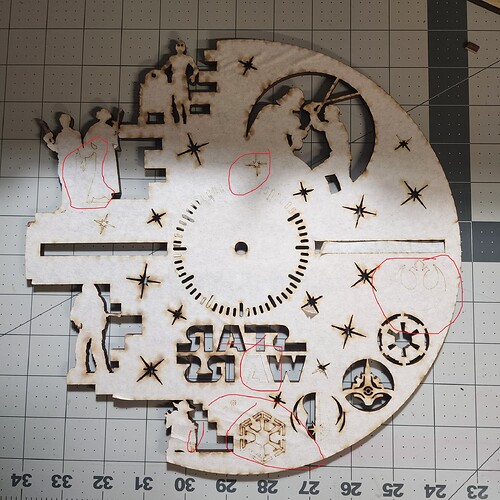

I double and triple checked the mirror. I did a test cut of a wine caddy thing we make, it engraved and then cut through just fine. Then tried to cut this fun little clock I have made many times before… the places it did not cut through in a randomish fashion was puzzling. Post pics of the results of the non cut. Also this is on the backside, so the pieces not cut are actually more on the left side of the glowforge.

not an issue with the file as it has cut this many times. Just recently stopped cutting this. It is proofgrade walnut setting I use 1/4" (so thick). If I do two passes, or slow it down I can cut through but trying to discern with cleaned lenses (all of them) why I am having to do that now all of a sudden. And why some parts cut thorough perfectly fine.

I would check for 3 things. Is your board laying completely flat on the crumb tray? Are all of your optics clean? And lastly are you cutting something other than proof grade? There can be areas in plywood that are difficult to cut through.

i second what @davidgal2 says. especially if you are using non proofgrade plywood. the fillers used in plywood can be very laser resistant.

Boards are flat and held down with pins. Optics are clean. It is not proofgrade but I have been cutting this laser ready wood from homedepot for 3 years now and this is the first time it has given me an issue. secondly I had another laser wood I ordered from a maker on etsy that I have used for 3 years, and that is 1/8" cherry wood that used to cut through fine and now has given me similar issues. I might have to just resign to the fact my machine is somehow messedup and enjoy the fact that I now have to do two passes on every cut?!