Yah I generally clean the window to the left, and the lens inside the print head. Normally I never touch the other lens inside the print head that is angled. It does cut better on the right side than the left side actually so that is strange too. Top of the board cuts are fine just do not go all the way through in areas of the cut on the back side. I don’t have proofgrade but was going to run a few more cuts. I first noticed it when trying to cut 1/4" walnut plywood and then again cutting 1/8" cherry wood too. After I cleaned the windows. Also i did clean the air assist fan a while ago, thought maybe I jacked the belt tension up putting that back on? But this issue doesn’t feel like a belt tension issue.

Just did another cut. Made sure all lenses were clean. Ran a proof grade thick walnut cut on a board from homedepot I have cut many many many times before. Result was, cut all the way through left of glowforge, top, and top right, not the bottom right. Out of ideas, how do you tell support to boost the power? This is so strange.

Bottom right only is 90% of the time that the mirror under the left edge is dirty/damaged, or misfocused. Most of the time misfocused is discovered upon first receiving the laser, so unless you were under there banging around that’s unlikely.

Yah I did give it a pretty good clean of that air assist fan and also did do the lid , and sucked out the exhaust on the back end with a vaccum so that is all I did, and it worked fine after that it was quite a few weeks ago. So now, not sure I even cleaned the inside the head angled mirror too and same issue. I did just think I have cleaned the main lens but not really wipe down the other two tiny lenses on the print head…maybe I should give those a wipe down (they don’t look dirty though).

Any time there is a difficulty in cutring through on the right (and not an issue with the material) it will be the same cause, The window under the left is not clean.

This is not a case of slow buildup but an instant situation when smoke is lying against the window as the laser is being fired, thus frying the bit of smoke to the window. The amount may be tiny, and it certainly gets worse over time. But the slightest blurring will cause less power to be delivered on the right side vs the left.

Any time I see the issue I clean that window. There have been times when I could not even see the problem, but the Ziess wipe comes up with a light brown stain, and the problem is solved so I know it was the issue.

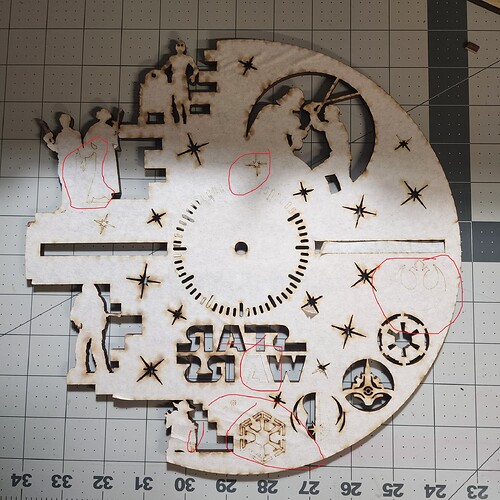

I double and triple checked the mirror. I did a test cut of a wine caddy thing we make, it engraved and then cut through just fine. Then tried to cut this fun little clock I have made many times before… the places it did not cut through in a randomish fashion was puzzling. Post pics of the results of the non cut. Also this is on the backside, so the pieces not cut are actually more on the left side of the glowforge.

not an issue with the file as it has cut this many times. Just recently stopped cutting this. It is proofgrade walnut setting I use 1/4" (so thick). If I do two passes, or slow it down I can cut through but trying to discern with cleaned lenses (all of them) why I am having to do that now all of a sudden. And why some parts cut thorough perfectly fine.

I would check for 3 things. Is your board laying completely flat on the crumb tray? Are all of your optics clean? And lastly are you cutting something other than proof grade? There can be areas in plywood that are difficult to cut through.

i second what @davidgal2 says. especially if you are using non proofgrade plywood. the fillers used in plywood can be very laser resistant.

Boards are flat and held down with pins. Optics are clean. It is not proofgrade but I have been cutting this laser ready wood from homedepot for 3 years now and this is the first time it has given me an issue. secondly I had another laser wood I ordered from a maker on etsy that I have used for 3 years, and that is 1/8" cherry wood that used to cut through fine and now has given me similar issues. I might have to just resign to the fact my machine is somehow messedup and enjoy the fact that I now have to do two passes on every cut?!

What you show is very obviously a case of the material, and not your Glowforge. I have a photo like that also…

This is rather an extreme example (The small bits in the center burned ayay completely and part did not cut through at all.) Some folks hsve shown lights through the wood to find such places but I have not had a light capable of the job for the wood I have had. If I had that problem I do not buy it a second time from that source. And if not specifically sold for laser then the question can be considered open. Even as bad as that piece was, I did get a bit of work done if awful still managed to not get the worst bits in important places.

The best way to double check material is to hold a flashlight up against it - voids or solid glue will show as light or dark areas - once you mark them you can avoid cutting over that area.

One of the reasons that PG is so much more expensive is because they guarantee it. I also generally buy from other laser sellers, but I still check for voids/inclusions.

Agree completely. I use a light all the time when I’m running anything non proof grade. I work around the void(s) and the rest goes into the bin for the fire pit ![]()

So not sure if anyone will see this but picking this topic backup. I realize the cut issues remain from all diff kinds of materials, but something I didn’t mention in the original post was that there is a hell of a noise coming from the glowforge when the gantry moves up and down (not the print head part) like a bad vibration of sorts. I am 99.9% certain this noise is new and probably started the same time the material cutting issues arose. Not sure what to investigate, the y axis belts on each side?

Yes, we still see it.

Why don’t you post a picture of the window under the left edge, and a video of the noise (upload it to YouTube or Vimeo or equivalent and post the link here). That way we can help based on actual data, not our assumptions based on your words.

Attached are the images of the windows. Attached is example of it not cutting through, this is on draftboard now. So I do not believe still it is a material issue. Three different types of material (1/4" walnut plywood meant for lasers, 1/8" cherry wood and now 1/8" draft board. ). All materials were flat and or/pinned flat and usually cut success happens by slowing the speeds down a tad which I have never had to do before.

This is after cleaning every lens and trying a cut too.

The noise was still there slightly after I tightened the belt on the right. I couldn’t get a good vid of it because it was far less prominent. It sounds like a rattling, vibration almost. By hand moving the turned off glowforge gantry I can hear a noise that is new, similar to the vibration I was hearing when running. Did post that vid to vimeo here: Glowforge sound on Vimeo

It looks like there are two spots on the underside window

See if those come off!

and I concur, that sound is not right. It almost sounds as if the rubber belt is snagging. Have you taken it off and looked for broken teeth?

I have not, I have taken the print head and assist fan off before…not the other gantry though since it has the laser tube on it I was nervous to do anything about it to investigate. Not sure how I would safely do that, could that be causing the no cut through issues?

Likely the dots on the window are causing the no-cut through.

A damaged belt might be causing the weird noise. Instructions for removing the belt so you can inspect it are here:

I have seen a mess far less than those two dots stopping a complete cut through. I had the cut through issue and those windows were my first thought. Looking, I could not see the slightest crud, but as I had the lens wipe out and opened rubbed it down just for luck and was surprised to see it slightly brown , so I wiped both windows and the cut through issue vanished.

This topic was automatically closed after 30 days. New replies are no longer allowed.