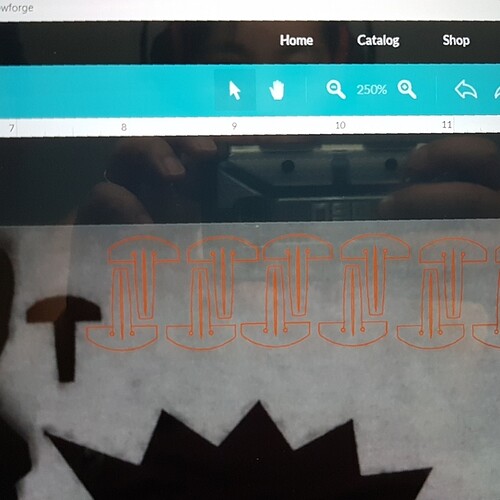

The material is on the bed centre but the alignment is off. I notice it never been spot further away from the centre to the interface but never this off. Wondering if this is a machine issue or is it a operator issue?

Probably a material distance from the camera issue. Could be a 1/32" warp, crumb, or shift of the tray in its divots.

Could also be the head got bumped after calibration.

H;ad you done a lot of jobs without shutoff and restart? Did you do other materials? Other thicknesses? There is creep at times.

I just cleaned the machine so I know the tray is sitting in the divots. I printed it right after start up calibration. The only thing is warp but that’s why I cut the hold down pins in the first place because I just cut proofgrade so I can get that half inch that gets cut off on the edges and I know I probably bent the wood

I’ve done jobs that cut properly on different wood types both proofgrade and non-proofgrade of varying thickness. I always measure the material and input accordingly. It’s always lined up well I cut from under the camera. I noticed the alignment shifts the further away from the centre which I attribute to the fish eye of the camera.

At first I thought it was me due to learning but I’m starting to think it’s the machine as it shouldn’t be that off on alignment from the camera to the cut. 1 or 2 mm yes, but that far off, should it be?

Is the camera firmly attached to lid. I wonder if you disturbed it when cleaning.

If the job is central under the camera the distance should have very little effect. It would scale the outline rather than offset it.

I just lightly wiped it. It seems secure. Has anyone reported to be lose?

Not that I remember but some people’s camera view makes rectangular boards look tapered. That implies the camera is not pointing straight down. I wonder if the sensor can be loose in its housing. For example Raspberry Pi cameras have a sensor stuck onto a PCB and I have known them to come loose.

Keep in mind that the machine is considered in spec if alignment is within 0.25”, and 2mm is only a little over .07”. Hopefully that will be improving.

Yes, but the scaled outline would cause the artifact reported since the offset that is noticable is at about x=7" and y=2" and the image is stretched in both directions away from the camera coordinate.

Yes I took “the material is in the centre of the bed” to mean the bit being used was. To get accurate alignment that needs to be the case.

Thanks! I will check the camera again when I get home

The software on your Glowforge is responsible for ensuring that the print lands on the material in the same place as the preview. When you’re done with a print, let a new image load. If the print appears on screen far from where it was supposed to go, you may have an alignment problem.

Most alignment problems come from the material being closer or farther from the camera than expected. While the software is still improving, you can take these steps for the most accurate alignment results:

- Use Proofgrade™ materials.

- If you don’t use Proofgrade materials, use a precision set of calipers to measure your material, and enter the thickness in the “uncertified materials” dialog.

- Use material that is not warped or tilted.

- Place your design near the center of the bed.

- Clean the area underneath your crumb tray, particularly the four indentations on the floor.

- Reboot the machine. Alignment can drift over time, particularly if you bump the head of your Glowforge while removing material.

Should you finish all of these steps, and find that you have an alignment error of more than 1/4", please contact us so we can investigate.

It’s been a little while since I’ve seen any replies on this thread so I’m going to close it. If you still need help with this please either start a new thread or email support@glowforge.com.