Old enough to have a pilot’s license.

19

Am I able to cut this? What do you guys think? I tried looking for EPA EPS and whatnot but couldn’t find the description. It does say Chlorine free, but is that all I’m looking for?

That’s a lot thicker than any foam I’ve cut.

I am just one person with a semi informed opinion…

I’d personally go for it. It’s an open cell foam, not very dense. I bet the laser will cut it easily. If I were trying this, I’d make sure I was cutting very quickly, speed 300, maybe 350, no lower. Foil can be melty and can be a fire risk, cutting very quickly is a good way to fight those risks, even if it takes multiple passes.

Also, with any material that is potentially melty or might burn, I’d stick to simpler designs without very fine details.

If you’re not familiar with my testing method, check out #6:

As per above about larger/simpler designs, I’d probably scale that test up to be an inch tall or so.

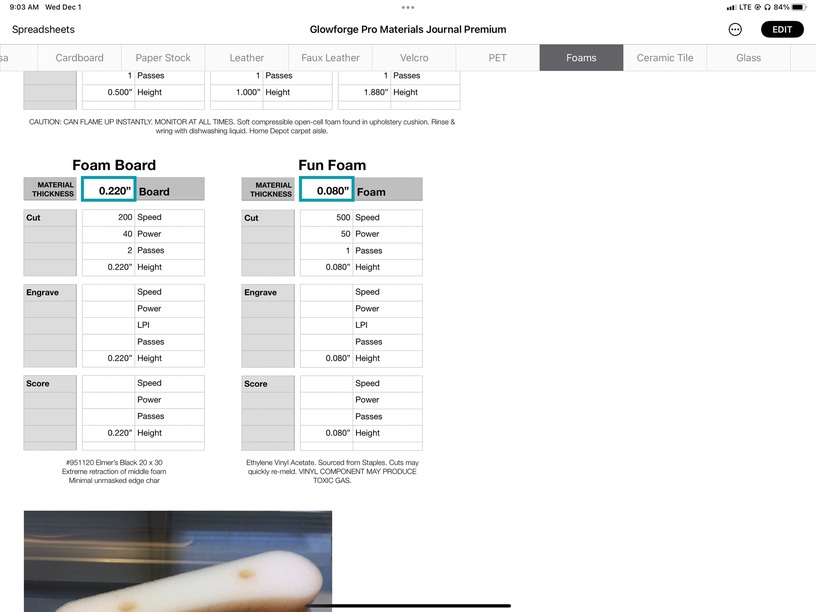

The Feldherr looks very similar to an Elmer’s brand I cut several months back. Same black color throughout. The Elmer’s I had on-hand is thinner at 0.22". The settings I ultimately settled on was worthy enough to put into my journal under “Foam Board” (notes section contains part number)

The card stock “skin” remained intact, but the laser will cause the sandwiched middle foam to retract severely… like rolling an eraser “marble” throughout the edge. If the project relies on those edges to be perfectly 90º straight, this type of board will disappoint.

In my case, I was using it to just make rigid signage. Oversized tabloid-size paper printed on a wide-format Epson, then spray-adhered to this type of foam board, followed by using the Glowforge to cut perfect holes for hanging.

This wouldn’t be the type of board I’d use to create anything structural that brings attention to the edges (square tooth joints)

I didn’t see any flaming of my foam at the thickness & settings I was working with, but for your 10mm version, the further slowdown in head speed required might yield very different (worse) characteristics… and it’s certainly much taller than what could slide through the Pro’s slot.

The Elmer’s version is a huge poster-board size, but wasn’t too difficult to trim down using a straight-edge and a fresh box cutter blade.

I’ve had one of these rabbet cutters since my college days building theatrical models.

My professors made us learn how to cut them with an xacto and metal ruler before letting us use this tool.

@ninyo , did you try that Feldherr stuff? If so, how did it go?