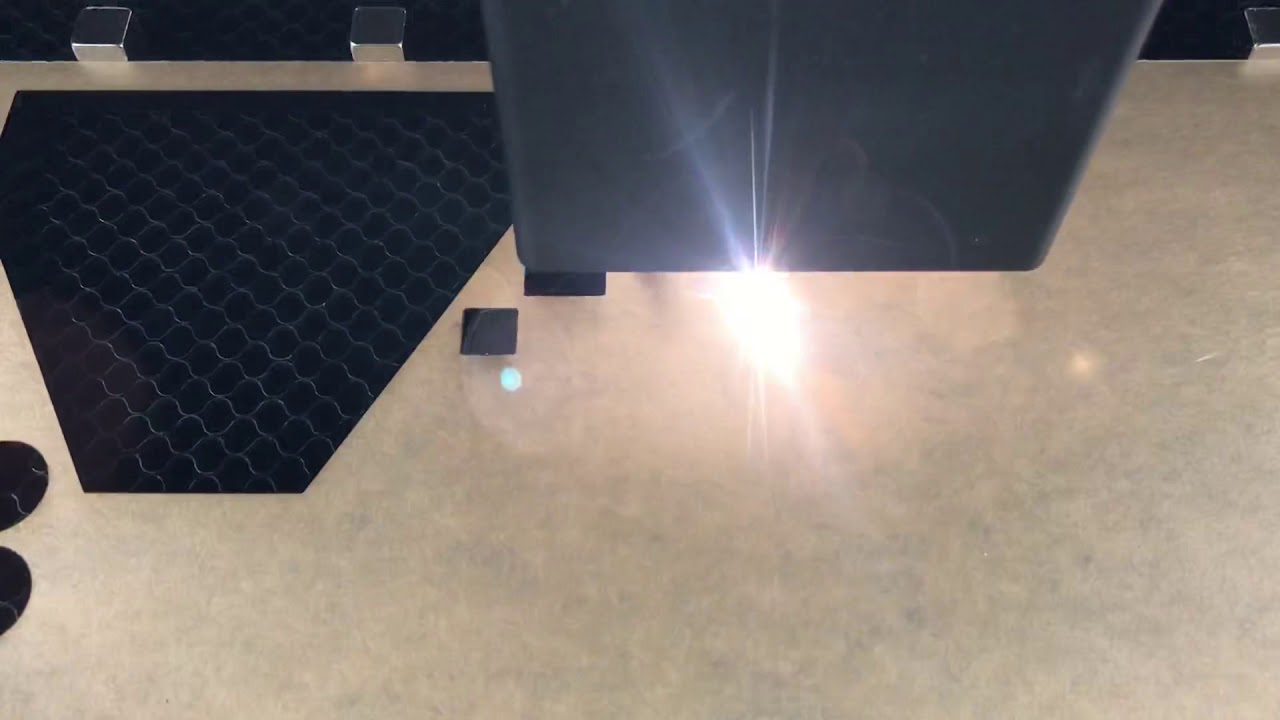

That amount of flame indicates to me that there is air feeding in underneath the acrylic. When you press down on it in that spot, does it give? (Looks like it might be just slightly warped around the older cuts…and it doesn’t take much warp to effect a cut. As little as a mm will do it.)

Try cutting your shape in another spot on the acrylic, away from those open cuts, and away from the edges…at least a quarter inch…see if you still see that much flame.

And these honeycomb pins work much better than magnets for flattening material: Honeycomb bed holdown pins If you want to cut near an old cut, use a few of these in the cuts to pin it down really tight.

(That amount of flame is not excessive, and it looks like your air assist is handling it just fine. It just usually indicates that there is air feeding into the material at the base. That’s when I generally see it. You might be able to cut it down by laying down masking tape on the grid.)

You might also want to consider removing the masking.

The piece is really flat, doesn’t give anything at all. Checked it with a ruler.

It seams to be an issue with the auto focus, I tried to enter the material thickness manually and its working fine like that.

Does it happen on PG acrylic?

Yeah, having the correct material height in there would do it.

Yes indeed  . But still, if I enter the material thickness to 1/4" (or use PG ) and enter 0 for focus height (auto) it should work. I like the auto focus, it normally gives a really good result.

. But still, if I enter the material thickness to 1/4" (or use PG ) and enter 0 for focus height (auto) it should work. I like the auto focus, it normally gives a really good result.

Good thing is, I can at least continue with the project now

Yeah, when you use PG settings, the height that is auto-populated into the slot for Focus Height is the height of PG material that you have chosen, not necessarily the actual thickness of the material you are cutting.

Glad you figured it out though.

You’re assuming the ![]() and your material are the exact same thickness. You always need to measure non-

and your material are the exact same thickness. You always need to measure non-![]() materials.

materials.

If I understand things correct. The material thickness is only for the alignment of the lid camera, in the case I set focus height to 0. (It gets to auto). Then the thickness should be measured before the cut automatically I guess ?

And it doesn’t change the fact that it today doesn’t focus correctly with that method but it did yesterday. With the same piece of acrylic, same method.

Still seams like something is off with the auto focus. I’ll do some tests later with PG material to see for sure.

Color matters.

I had some great working numbers for goofgrade acrylic and had to modify them when I went into greens and teals.

Same problem with two color black/white. First engraves with my magic numbers did not burn off all the black, and had a pebble look to it until I modified the settings.

I’m confused here because Proofgrade is going to set the material height and focal height automatically for you. If you are going in and changing the focal height to zero, you are overriding the autofocus.

The material height field will auto populate the focal height field.

If the material height field and focal height fields are the same, the scanning process will determine a material height and set the auto focus to the measured material height.

If you set your own focal height that differs from the material height, the autofocus function is not used. You are effectively overriding it.

I’ve noticed this on print and cut, but can say that for Proofgrade materials, at least when I recorded the values in early July (or maybe earlier), they were using universal thick acrylic settings (applicable to all colors).

However, since we aren’t talking about Proofgrade materials, that point is basically moot.

Not quite. There are two focusing operations going on in there.

First you enter the actual material thickness into the Unknown Materials slot. That does two things. One - it compensates for the fisheye effect on the lid camera in the algorithm that makes visual placement more (or less) accurate.

But it also auto-populates that material thickness into the slot for the beam focal point in the individual operations. (That is a time saver for us, so we don’t have to set it in every operation.)

Then if you come along and use the dropdown to load Proofgrade settings without actually keying the values in Manually, the actual material thickness gets replaced by the thickness of the Proofgrade material that you selected in each of the Focal Point slots for all of those operations. And that might not be the same as the actual thickness you are using. (You can play with the settings and watch it happen.)

For the visual placement, you want the material thickness to be accurate, so the number that goes into the Unknown Materials slot needs to be the actual thickness.

So if you’re shooting for accuracy on non-PG materials, the correct method is to either load the actual material thickness in the Unknown Materials slot first, then hand code the correct Power and Speed settings for each operation…or…do the visual placement first, load the dropdown PG values, then go in and hand code the actual material thickness for focal point of the beam in each of the operations. It’s slightly easier, so that’s what I generally do.

Does that make it any clearer? Two focusing operations going on. (And you never set the focal point at zero…that will point the beam at the base of the material, and that really makes a mess with the kerf.)

Are you 100% sure it gets the focus at 0.00" if I enter 0 ? because when I enter 0, it automatically goes to auto. I thought writing 0 “entered” autofocus mode.

Maybe I miss understood it. But how come it worked doing like that 3 days ago, but not today ?

No, I’m not 100% sure of anything because things change with each release, and I have never relied on auto-anything being loaded for me. If you test it and determine something different, you should definitely share it with everyone else.

Yes sure, trust me I will try it out

The problem right now is that I’m not really sure that part of my GF i working like is should.

Hopefully someone from  can let us know how it is working.

can let us know how it is working.

Anyhow… thanks everybody for the help

Not sure why you are entering a focus height at all if you want auto. The material height is not transferred to the focus. It should be empty unless you enter something. Though I haven’t looked at the updated interface to confirm. So just leave it empty and auto focus will be used

Yes it is, If you enter material height, it’s also transferres to focus height.

Thanks for reaching out.

I can confirm the settings for Proofgrade Thick Black Acrylic have not changed recently.

Regarding the focus on your prints, the Printer Head moves to approximately the center of your print and uses the red light to take a measurement of the material. I extracted the logs for your unit to investigate the print. Because the design you are printing is small, it’s possible for the red light used by the autofocuser to fall outside of your design. If your design is placed close to the material edge, the autofocuser could miss your material, resulting in the focus being set incorrectly. I’ve let the team know about this. In the meantime, if you see this kind of behavior, try placing your design further to the right of the material edge.