Some of us are very good at that. Years of practice. Hah

Very cool. At my old job we had a Fiber laser like that. They are so fast.

I have no idea what a fiber laser is or what a lower receiver is, but I liked it all nonetheless.

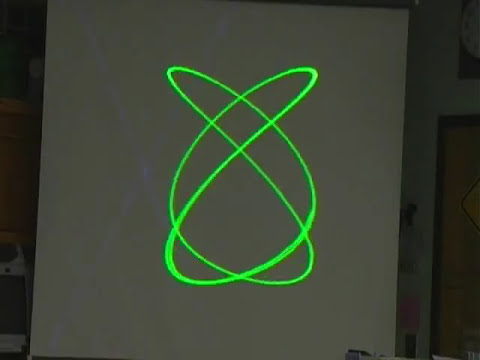

The speed shown in these videos comes from more than just being a fiber laser. I believe they’re galvo-based systems. In that type of laser-marker the laser beam is bounced through two mirrors. Each mirror can be rotated very precisely and the combination of the rotation of the two mirrors allows the beam to be aimed at any point within a certain area. This means going from one edge of that area to the other only requires a small rotation of a mirror instead of moving a relatively large physical object many inches.

From what I’ve seen, galvo lasers are limited to “marking” (not cutting) because the angle that the laser strikes the material varies quite a bit, which means any cuts made with it would not have a square edge.

Some mirrors attached to galvos are shown at 0:55 in this video (and also in the thumbnail).

Another good shot is in this video starting at 5:42.

This further confirms my suspicion that the Glowforge is a bona-fide slippery-slope-rabbit-hole-to-even-bigger-toys-gateway-drug.

Does anyone know if there is a laser equivalent to the Hydraulic Press Channel (YouTube)?

I will be watching it if I find it. emphasized text

So, a channel where they just put random things in the laser and slice?

Isn’t that how Joshforge got messed up?![]()

This is awesome. Can anyone explain what’s going on in the second pass vs the first?

I’m sure that mad Finn will end up cutting and slicing before long, may not be a laser, although he’s halfway there with his parabolic mirror.

I can haz cookie and coffee now ? oh and a sock ?

That is a very interesting technique and very efficient for conserving movement - resulting in the incredible speed. In the middle would be a moving laser head (as our GF has), and at the other end of the spectrum (there is some kind of pun there…) would be a fixed laser and moving media. I don’t know if that exists, or if there would be any context in which it would be beneficial.

Thanks for sharing. I love learning about different approaches to technical problems.

This is the closest I’ve seen, Alan Reeves on Vimeo: can you etch it?

I just can’t help but wonder fi that might have been quicker if it been done with vectors. or even rotated 90 since there are so many lines with so little drawn per pass.

Hard to say if it would be much different. more short passes would typically be faster though, since non-engraving travel speeds can be faster.

The main question would be total travel distance while at cutting speed. So you want the direction with the most short lines from one side to the next (in a vaguely square net envelope).

The start and end of the cut had shorter pass lengths than the middle in this orientation. If rotated then you still have shorter passes under “Cook,” but not much shorter at the other end.

Doing it by vector probably would be faster, since there are large voids. But I haven’t seen any software that breaks down a job in concentric vector lines. Which would be much harder anyway, and would require that all engraved spaces are the same width, and a multiple of the kerf width. Or if width ever changes, it changes one full kerf at a time, no continual slopes. (Otherwise you have some spots which get double engraved, so lose uniformity in engraving depth)

My thought on rotating it is head travel seems much faster left to right, and the engraved image seems to have more needing burn points per raster line and it’s not seemingly a square image, so the rotation might pick up some efficiencies there. But as you say speed moving vs burning is another wrinkle.

also wow. what a crazy interesting algorithm/software problem, the concentric vector lines. I’m going to have to try and play with that just to make my mind give me peace on it.

Grab the slicer software for any 3D printer, and tell it to use concentric infill, at 100%. Then look at a single slice of the resulting model and notice all of the voids at the tips of various pathways.

Far better to watch an actual print while concentric infill is being used, but the software shows you actual straight lines, while in real printing since the filament is semi-liquid there is some settling which fills in quite a few of the gaps.

You do contour fill in CorelDraw that would do just that. Never tested that vs. Raster, but maybe on Tuesday I can try two identical boxes, one rastered and one done with vectors and time each one…

Would be nifty to see the results. The vector OUGHT to win. But the raster will probably have the better look to the final product.