There are several of us who also own one of the Chinese 40W (or more even) lasers. The short answer is that technically a 40W CO2 is capable of the same things. So what the GF cuts or engraves the others will too.

But the reality of the actual implementations of the technology is that the Chinese lasers represent a device that meets minimum specifications or capabilities. The GF represents a product that is built to higher quality specifications that results in better performance. So I get more consistent results over a variety of materials with the GF Pre-Release unit I have than I get with either my K40 or the 60W Redsail.

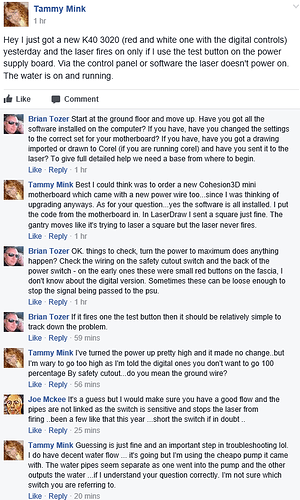

Almost all K40s (those 40W $500 lasers) have issues with their components. They all have external cooling pumps that you place in a bucket of water and hook to the machine. It’s a repurposed pump usually used for water gardens. If it comes with air assist it’s air pump is either an aquarium pump or small general purpose air pump. The mirrors & lens are the smallest & cheapest that will work. The electronics are generally sketchy - minimally capable of supporting just the base components in the machine. Often the wiring is not actually connected correctly - one of your first tasks is to check that before you fire it up and wire the grounds correctly.

On top of better hardware (Tesla vs Yugo), the software used is miles better than the Chinese lasers. Those lasers ship with two packages - a machine control software that is cryptic, undocumented and supports 1 operation at a time. The design software bundled with the machine is a pirated copy of Corel Draw from about 10 years ago. If you read Chinese you may be able to read some of the documents that ship with the K40.

The Glowforge control software is documented, supported and allows for many operations in a job (combinations of cuts and engraves in a single job). This is far more streamlined than the K40 and much more robust as well. Oh, and it’s all in English.

The K40 (that’s a general term for all of these cheap 40W machines) is generally unsupported - your most likely fix for any problem is potentially a token refund of money when your tube dies or the power supply shorts out. You’ll usually be left on your own to source and install the part. You’re also limited not by the usual “2 year warranty” period but the 60 or 90 day dispute period you payment method provides. Once you can’t dispute the charge your emails will generally not be returned and you’re on your own.

Google K40 lasers and you’ll find a lot of info on how to modify it. Replacing the lens, mirrors and electronics are common mods. Add safety features is also an area where you’ll find a fair amount of modification information on the Internet (from the factory these don’t usually have any safety features installed to prevent laser operation with the lid opened for instance). We all modify our K40s  It’s a tinkerer’s machine. If you get a good one and are able to use the software you can use it stock, but that’s not the norm. Usually you have to tweak it. Lifespan of major components tends to be a year or less so you can wait for the parts to fail and then implement your upgrades. You just need to be comfortable swapping parts and a bit of rewiring.

It’s a tinkerer’s machine. If you get a good one and are able to use the software you can use it stock, but that’s not the norm. Usually you have to tweak it. Lifespan of major components tends to be a year or less so you can wait for the parts to fail and then implement your upgrades. You just need to be comfortable swapping parts and a bit of rewiring.

One thing you get with the K40 machines you won’t get with the GF is the ability to engrave thicker materials (Glowforges have a much larger bed than the standard K40). You can get a 2" thick piece in the GF but you can get 4-6" material in most K40s.

If you’re not a tinkerer and comfortable with electronics and expect it to just work out of the box both hardware and software, the K40 machines are going to disappoint you. The GF just works.

Best of luck with your decision. But as a point of reference, I have a K40 and have not turned it on since March. I also have only used the 60W Redsail once. Everything else I’ve done has been on the Pre-release machine GF gave me to use to help shake it out. I have a Pro on order and will likely jettison the K40 when I find the time to scrap it. It was a nice way to get an education but it’s not a “forever” machine for me. I am an engineer but I’m not using the laser in a business.

. I’m all for ease of use, I just don’t know if it’s worth $1800. And not to be too salty, but I could have a K40 before GF announces the next delay… Hmmm, decisions, decisions.

. I’m all for ease of use, I just don’t know if it’s worth $1800. And not to be too salty, but I could have a K40 before GF announces the next delay… Hmmm, decisions, decisions.