Hey all. I’m working on some board game tokens with a pretty small diameter (around the size of a dime) and I’m struggling with cutting the circle. I know, I know… Not hard, right? There main issue is that I can’t get rid of the burr or tick where the laser begins and ends the circle cut. I’ve tried using little curved lead in lines after reading some advice here on the forums, but they actually come out worse, maybe. I think it’s because the circle is so small… I wouldn’t think it’s that big a deal, but I’m using the fluorescent yellow PG acrylic so every little line is very noticeable. Has anyone found a fool-proof method for either creating lead-ins on a small circle or maybe using an overlapping path or something? Or is this just one of those things I’ll always have to deal with because lasers?

This might get bumped from problems and support or maybe not.

But - can you upload your SVG with the lead-in that you did?

I find the little blip pretty minor, but if it’s showing too badly in whatever acrylic you’re using you can try this - it is imperative that you perfectly align the top of the circle to the line before cutting up the circle and the line and reconnecting them in the configuration shown.

(Lot of work to avoid a blip, but it does work.)

I did try this. That’s what I meant by lead-ins. I was surprised that it came out worse, and like I was saying I think it’s because it’s so small…

I mean, it’s just a vector circle. I tried several versions with and without lead-ins of various types and sizes. Results were the same for all of them.

Can you post a photo? I’ve seen a burr on mine and am wondering how it looks on yours.

Ok then…

How you are designing the lead in makes a difference. Where you have your start points and end points for the path; whether you just drew a lead in and didn’t connect your paths. Etc.

Part of the problem might be that acrylic is so melty - it is actually getting double zapped where the overlap occurs, or where the end point happens, although you hope with the overlap it’s moving fast enough to not do too badly.

I wonder if removing half a kerf width of path from the circle would help.

I need to cut some acrylic this afternoon - I might play with it on some scraps if I get a chance.

I think this is the problem with the lead in for sure. With such a small amount of material to work with I think the heat is causing problems. I’d rather not extend the leads too far anyway since this will affect production.

This image shows a test with lead-ins. Even though the Illustrator file showed the anchors matching perfectly, there’s a bit of extra material bitten off, as Jules suggested probably due to heat distortion.

This image shows no lead in at all, and a little dot where the line started and finished.

Okay, I got something that works…(and yeah, the heat melts a flat spot in the acrylic when you overlap the path, so that’s out).

But this works:

Put a 0.05 mm gap at the top of the circle…results are almost perfect.

(Yes there is still a faint visible line, but it’s the nature of the material I’m afraid. You can’t find it unless you run your fingernail along the edge.)

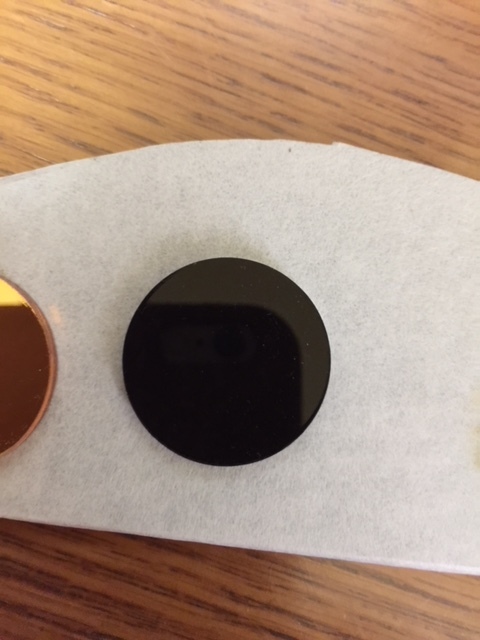

Opaque acrylics come out practically perfect, and the single line is not really noticeable on mirrored either until you get within an inch or so:

I will certainly give this a try! I would never have guessed this on my own but it makes a lot of sense now that you mention it.

Thanks for the suggestion, @Jules.

@BeamGeeks

I’m sorry your tokens didn’t print the way you expected. Please let us know how the next prints go!

I did some last night. They looked better for sure with the little gap (thanks @Jules!) but there’s still a tiny tick. I noticed the laser path is actually slightly thinner at the beginning of the cut than the end, possible due to a bit of warping from the heat? At any rate I decided they’re good enough. I really think it’s only noticeable because every little line glows in that fluorescent acrylic.

Thanks for the update. I’m glad that worked better!

I’m going to close this topic. Please post a new one if you have any other questions.