it is a JPEG and i don’t think so

Redo your settings with 1000/100/340 but don’t input a focus height and see what happens.

Still no luck

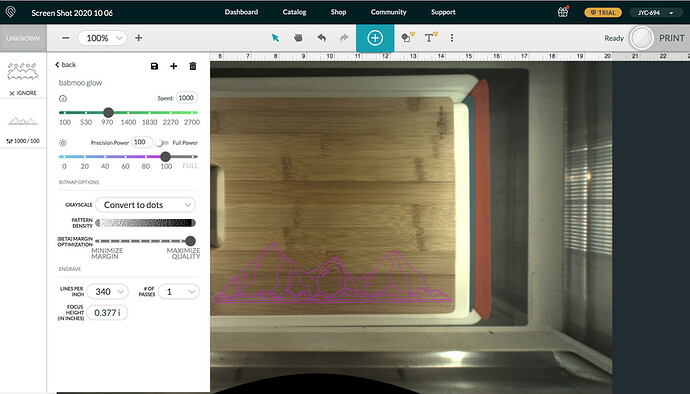

Can you share a screenshot of the entire interface - the art on the bed, the settings, etc.?

Have you completed any projects or is this one of your first?

I am stumped as to why it doesn’t fire. When two images are on top of one another, they cancel one another out and the laser will move but not fire. If you are sure it isn’t a file issue, I am out of ideas. If I was in this position, I would try printing a simple file I have used before to make sure the laser works and it is just this project that is failing.

If the laser head is moving like it is engraving, but the results aren’t showing up on the cutting board, check to make sure that the height information showing in the Focus Height slot there at 0.377 inches is correct. If that is hard coded and the actual height of the cutting board is lower, it might be defocused. 0.377 is pretty thick. What matters is the thickness of the material that appears above the 1.4" top of the grid.

(That height number might be off.)

Ok ill try that thank you very much for your help.

Or the red dot focus fell off the material. The artwork is near the bottom and the red dot could have been over to the left of the bamboo board.

ok so I measure the actually cutting board and put that in for the focus height.

The thickness of the board is not relevant with the honeycomb tray removed. What matters is the focus distance. Use the set focus tool and make sure you see the red beam hit the material where your artwork is.

Ok i will keep my eye out.

ok

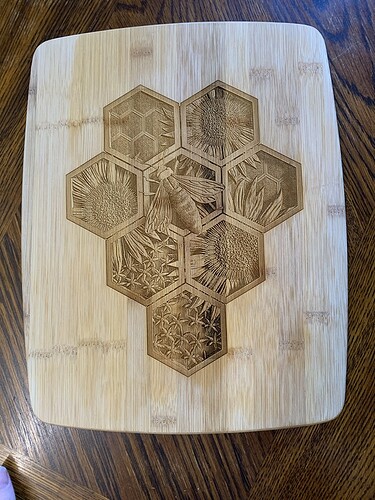

It was a file issue thank you so much for your help.

Hi. I can’t remember what riser I used. But another Glowforge user made a height calculator where you can determine the focus based on your material thickness. You should be able to find the riser files in the forums too.

Glowforge Focus Calculator.xlsx (34.1 KB)

Keep your crumb tray in. I use the same bamboo trays. they are only .37" thick, so no need to remove that tray. put the crumb tray in. enter that same thickness and it’ll work.

1000-100-340-1 pass no mask. I wash with dawn dish soap and a toothbrush after or use my orbital sander. Then when dry and dust free I oil with board or mineral oil.http://kerrie-stone-creations-art-handcraft.business.site

First of all, thank you for your input! I came here today looking for this exact answer since GF gave us that yummy holiday file for cutting boards. My question is why are people using risers? I’m new in the sense that I’ve only had success in PG materials and very basic files. I really wanna get better! TIA!!!