Hi!

I am having alignment issues again. So, I was trying to make some stuff on PG Black Acrylic, and the alignment was terrible. So, lately, I am having to factor in for maybe a half-inch alignment off to the right of the area that the app shows. I am trying recalibration again right now. However, I am wondering if I should be constantly running into this issue. The last time, it made it reasonably better, but it was not perfect. How often do you guys realign your machines? I always do the “Set Focus” prior to each print, even if I am working with the same materials or designs. I have also only had this for like a month and have made probably 1,200 ear savers and that’s it. So, it shouldn’t be crapping out already.

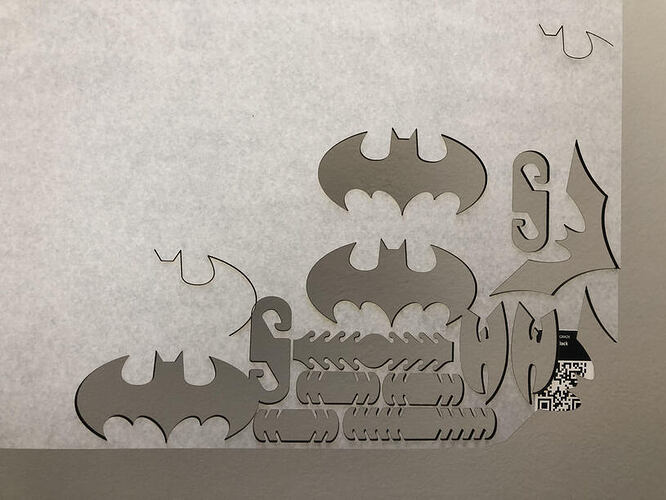

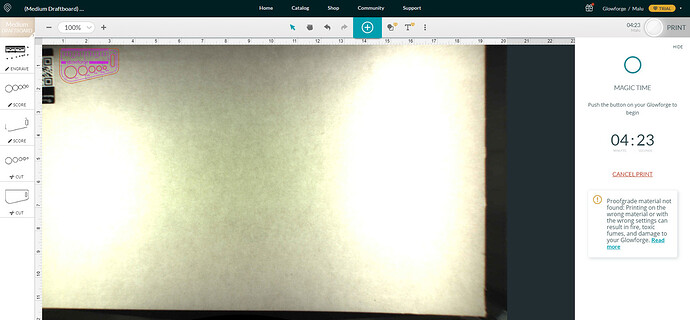

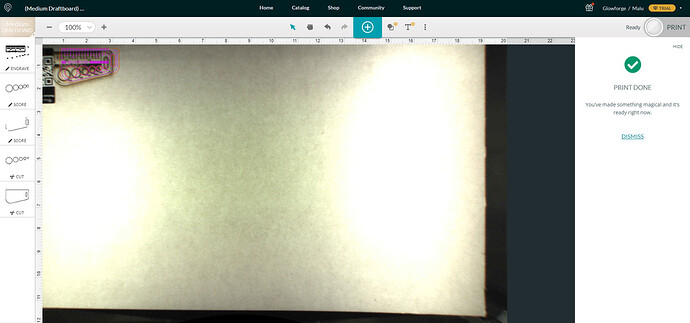

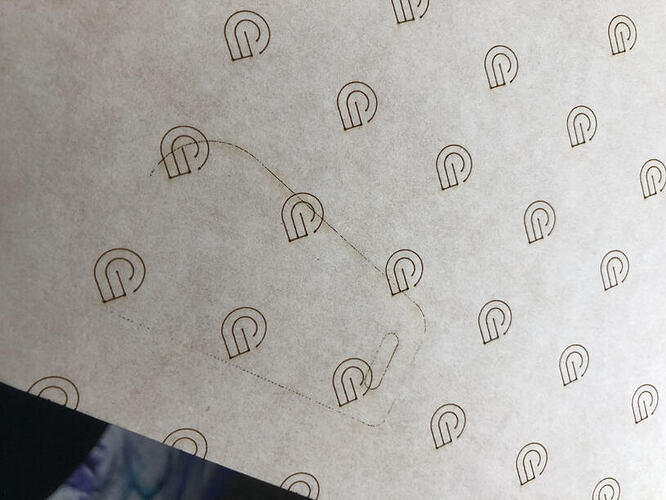

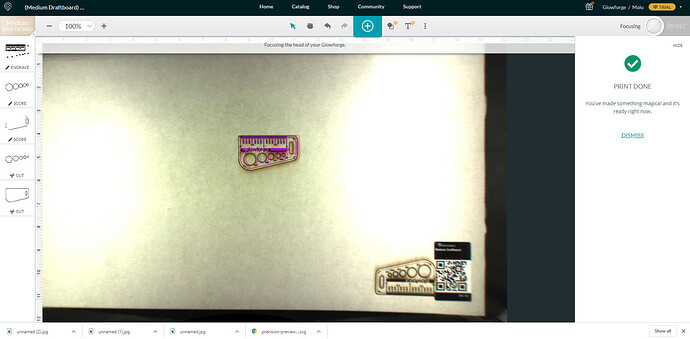

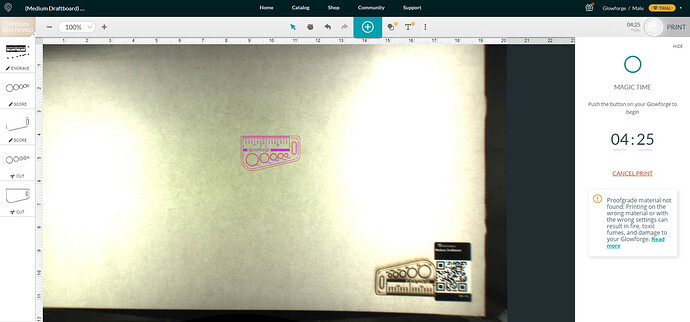

With the ear savers, it hasn’t really been an issue because the prints aren’t really specific. However, I plan to start making stuff that requires exact precision. So, I am hoping that someone or support can assist. I don’t want to be ruining my materials every other time. Sometimes, oddly, part of the print will be fine with alignment than it will wig out and mis-align and cut into my previous prints, which were in the same design during the same cutting (see photo). I stopped the print, as you can see, because it was just going to mess up what I had already done. I didn’t touch anything during the process. It has even marred part of the side of the honeycomb because the alignment was so off, even if it wasn’t supposed to in the app. It hasn’t affected the height of the honeycomb at all. Truthfully, it may have only ever printed with exact precision a few times. However, I thought laser was supposed to be consistently precise.

My GF is situated by a window, so I have natural daylight shining through. Or, at night, I have the fan light on. Does that matter? Should I be in a completely dark dungeon? I am trying calibration with the glass covered. So, no light should be affecting the calibration.

Does it matter that I am using a PC tablet as my means of accessing the app and printing? Could it be something with my computer’s software?

Can I not do other stuff in the GF app while it is simultaneously also working on a print? Not doing anything to the design being printed, but sometimes I’ll open a new tab and work in another design file while waiting for the print to be completed. Alignment seems to be off, even if I am not touching the computer and staring at the specs on the wall. But, just thinking of possibilities.

Would bumping the plastic table that it’s on affect the alignment? Is it that sensitive? And, by bump, I mean, my beer belly is touching the edge of the table when I take out the material… not actual bump. I’ve been very careful to not bump the machine. Does it matter if the plastic table is on carpet?

Thanks in advanced!!