Deleted

Deleted

besides the lid cable, there are no other electric things behind the panel, its sheet aluminum

and should be pretty easy to dremel cut - and the back of course is just molded plastic.

Just some notes, the GFUI will NOT recognize there is a pass through slot

you will need to design your project in pieces, and then manually align the materials

I may build in some kinda of ‘guide’ track so the material follows a straight path.

Deleted

Deleted

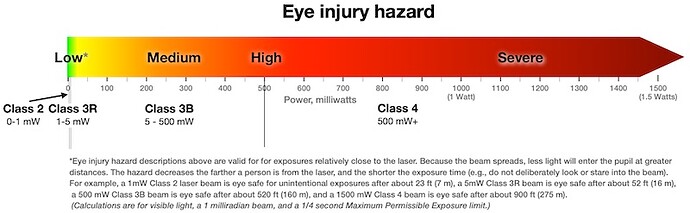

Lets take a moment to discuss laser safety glasses, This mod, makes this unit a safety hazard

and laser glasses MUST BE WORN when using the pass through, an errant reflexion, that hits your eyes will blind you… serious stuff here!

for $40 bucks you can buy a pair of laser safety glasses.

DO IT!

That sounds like a good thing, but you might have trouble getting the cat to lay flat as you close the lid. ![]()

its easy… like a cat scan …

Jonathan, I have the utmost admiration for your passion to push the envelope on Glowforge modifications (thanks for sharing your experiences), but I have to ask.

Have you considered the strain on the Glowforge casing after all the alterations? After all, the metal plate at the back holds the hinges for that heavy tempered glass door.

I ask because once I placed my Glowforge on a slightly uneaven surface and the top glass door became skewed and started rubbing against one side. Not until I leveled it, did the door close aligned as it should. At the time I didn´t think such a slight difference would have that consecuence.

You are a pioneer. Thanks for documenting all this.

when I mounted the glowforge on the cart, I made sure it was dead level, and it is completely supported on all sides, the glass lid fits perfectly square, and keeps out all smoke

so as far as I know, Its all good - If it ever explodes, I will take pics!

LOL!

Jonathan

I think I would be more afraid, If I didn’t strip a Broken Glowforge down to its frame,

and I completely understand how it all comes together.

By cutting the 1/2" slot into the frame, I am not compromising the structure in any way

(or remember that post before about glass exploding) ![]()

whatever I do, fabulous, or fail, I will document it.

Jonathan

I told the doctor I was catnapping too much and he thought I was part of some cat scam…

Deleted

Deleted

Deleted

Jigsaw and hacksaw blade next time, maybe? Dremel is maybe not the best tool for that job, all things considered. Jigsaw and plastic blade for the case might have been easier too?

i wanted something a BIT more precise then a jigsaw, I use a jigsaw to cut up a bathtub ![]()

Hmm I used to have a jig saw that was terrible, jumped all around, ragged cuts etc

Then I upgraded and got a modern one, bought better blades with higher tooth counts, and now I get really smooth cuts and can dial in how smooth I want the cuts to be (smoother and slower cut or rougher cut but it tears through the material). It’s all about the right tools, maybe time to upgrade?

Sorry, I just have to ask … why?