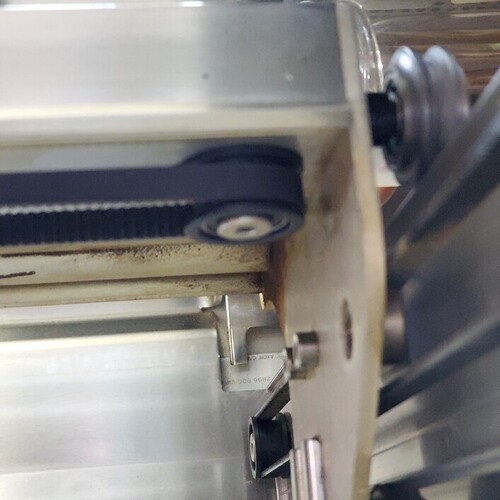

I noticed this morning that the laser head was moving bumpy. So I removed the laser head and belt and did another deep clean. Issue still remained. So I removed the belt and loosened the right idler pulley so I can readjust the tension on the belt. As I was loosening the pulley the screw just fell onto the metal surface of the Glowforge. I thought that was odd. It never just fell out like that before. So I attempted to put the screw, washer and wheel back. I was able to get it in but noticed that the black pulley wheel was not spinning naturally like before. I loosened it and the whole thing would become loose. I worked on this for 2 WHOLE HOURS this morning to no avail. No matter what I did the pulley would be tight and not spin. This causes the belt not move smoothly at all. Anyone have any ideas??

Can you take the wheel out and verify the bearing isn’t locked up?

I’m sorry which bearing? I removed the screw, washer, and the wheel. The third pic I uploaded shows where the pulley need to be put back into and its loose moves just like normal.

I may be mistaken but I believe that metal ring is where the bearing(s) are. Can you hold the inner ring and spin the outer?

The red arrow in this pic points to the bearing being referenced. The idler pulley is a pair of bearings stacked inside the plastic wheel, which are supposed to spin freely, and held in position by the 3mm Allen screw used to hold and secure them in position after tension has been set. You should be able to hold the idler pulley assembly by the center ring (the smaller metal ring that the screws touch) and spin the assembly that surrounds it. If you can’t, then one or both of the bearings have frozen and will need to be replaced.

Seems like that may be the problem. Its very sluggish but it does move.

Hi @samanthakonet - I’m sorry to hear you’ve run into this trouble.

Thanks to the awesome help from our community members @kanati and @yoyodyne2112 it sounds like we’ve already narrowed down that the pulley has frozen up and should be replaced.

I’m going to shoot an email your way to collect some information so we can go ahead and start the process of sending you a replacement part. Please keep an eye out!

Since we’ll be finishing via email I’m going to go ahead and close down this topic.