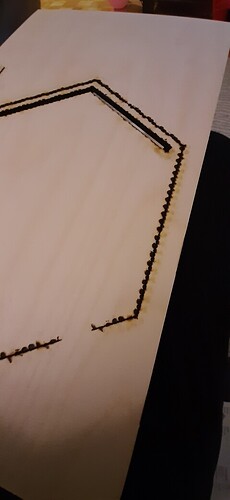

I haven’t had much glowforge for long and decided to try out some 0.25" birch plywood. It almost cut through but he back looks HORRIBLE. Is this normal? My settings was 115 speed at full power.

Welcome to the forum.

I think your speed is way too slow, and this could also be a problem with the material. Is this a speed and power you have had good luck with in earlier trials with this wood? If not, you must test your settings until the material cuts through. Also, masking would help reduce the flashback marks on the back.

But even at this low speed it hasn’t cut through. Is there anything else other than slowing the speed to improve my chances?

You must test. It could easily be the material.

Did you use calipers to measure the material or did you use the set focus tool?

Yes I used a caliper. Ok i will try masking on both sides and do more tests.

If you use the search function and search Birch Plywood you will find quite a few discussion threads. Many people have discussed the variable quality of this material, the glue pockets, knots and different material layers. When testing, there are several templates in the free file section.

Not cutting through in one spot while burning in another is indicative of fillers used in plywood. Standard birch plywood is kinda notorious for this - it’s why you see folks on the forum talking about Baltic Birch of specific grades - the better the grades the less filler.

If you hold that piece up to a flashlight on the back I’m betting you’ll see a big spot right over where it didn’t cut.

Check out #6.

You’re pumping way too much power into that cut - that “horrible” look is called flashback. Speed up the cut. As the others have mentioned the part that didn’t cut through is due to something junky in the wood layers there. You’re not going to be able to power through it.

To back up what @dklgood had mentioned, there was a conversation about 1/8 Birch a couple of weeks ago. Maybe it would be helpful to you: Corroboration on Laser Power

Yea, too much power causes the laser to bounce off the Crumb tray and burn nearby flammables. get some masking from Amazon, (https://www.amazon.com/Vinyl-Ease-Transfer-Silhouette-Adhesive/dp/B07DF7TDSF/ref=sr_1_2?dchild=1&keywords=laser+masking&qid=1617668693&sr=8-2) and coat the back of your work.

There’s also going to be a problem with the 1/4" Ply for any grade and facade. Most converters use the worst tramp material for the inner core. All those knots that are on the outside of the tree, they put those in the middle to save money. You’re never gonna burn through it. The speed your using is plenty sufficient to get through 1/4". I use 140spd @ 100power. Once you get a good cut, grab a sharp exacto knife and start cutting through the back. Large areas of detailed cuts truly reveal how horrible the quality can be.