I’ve never been too heavily concerned with the noise of the Glowforge, inside or outside. It’s about like a vacuum inside and I’m on 6 acres, so exterior noise isn’t much of an issue. However, an upcoming adventure may necessitate my paying attention to how much noise I’m making.

I picked up a 4” muffler/duct silencer to see what would happen.

VIVOSUN 4 Inch Noise Reducer Silencer for Inline Duct Fan https://www.amazon.com/dp/B01CTM0H1S/ref=cm_sw_r_cp_api_GfGBBbX611CQJ

It’s not without some problems that have to be fixed. As it is designed, 1. it’s just a slipfit onto the Glowforge flange and stays pretty loose, 2. The body is fat enough that it sits a bit too high to go straight on the flange, 3. You can’t clamp it because, well, the case doesn’t bend so well. After I raised the Glowforge a little bit with some 1/2” wood on the runners, I 3d printed an adapter that @marmak3261 had designed (I believe) but it didn’t fit very well for me. Need to scale it up a hair to fit the GF flange.

I ran some initial tests with the stock ducting vs the muffler and vowed to address the fit issues a little later. I just wanted to see if it worked.

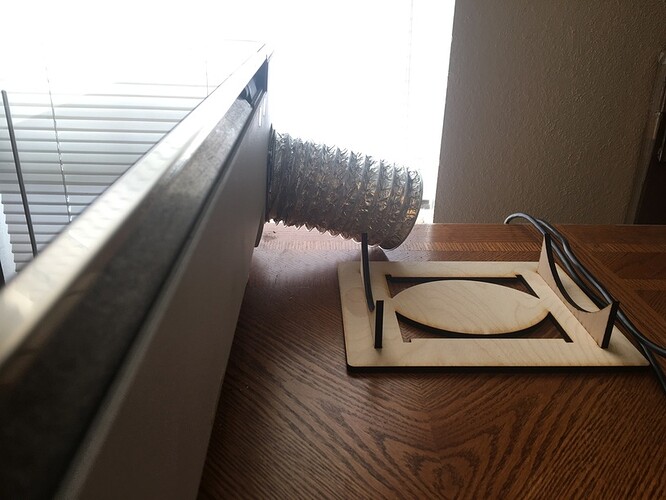

Then, I realized I was overthinking it. It doesn’t have to connect to the flange. Just cut my dryer duct and connect that to the flange and then the muffler, and then attach the rest of the dryer vent to the backside of the muffler to vent outside.

I also cut a simple little base to hold the muffler. Since it’s round… and it’s under pressure, it has a tendency to want to roll.

Cut ducting and base

First iteration

Second iteration:

I thought a couple of inches of dryer duct before the muffler wouldn’t make a big difference. It does. The muffler still works but a lot of noise escapes out of just those couple of inches. So, I readjusted things to have the muffler as close as possible to the exhaust flange. Much better.

So I ran a few tests over a couple of days. I used the NIOSH sound app set to dbA. I’m not as concerned about the actual decibels it shows. It’s an iPhone an app - so I looked more to the difference it showed vs the actual decibels it read.

Initial testing looked like this. I had the phone approximately 3 ft from the exhaust flange, at the backside of the machine by the power button.

Stock exhaust setup

Idle with glowforge on from 3 ft : 48dbA (before coolant pump kicked on? it jumped up to 54-55dbA after that happened)

Scanning:65 dbA max

Running with stock exhaust from 3 ft away: 75-76dBa

Running with stock exhaust measured from outside vent - 3ft : 63-64 dbA

With Muffler:

Scanning with muffler: 65dbA (didn’t expect a change)

Idle with muffler from 3ft: 48 dbA (didn’t expect a change)

Running with muffler from 3 ft away: 68-69 dbA

Running with muffler from outside vent 3ft: 54 db

I ran some other tests the next day, and my overall decibel readings were higher (saw a max of 81dB with stock exhaust) but the change was the same (hence not worrying about the actual decibels but just the relative difference between muffler and no-muffler).

A 7-8 decibel improvement. It feels almost half as loud…

Poking around today, I see that the exhaust is basically making no noise. The rest of the noise is from the stepper motors and the intake fans. I see the intake fans are rated at 210cfm and 64 decibels.

I know a while back @takitus built a cradle type system to go under his unit. I probably don’t want to do that but will investigate additional ideas to quiet down the intake side, if it can be done without restricting air flow (the muffler doesn’t impede exhaust flow - it’s filled with neoprene to absorb the sound waves). Like I said, I never thought the Glowforge was terribly loud. And it’s certainly not now… but why not see if I can make it even quieter, I guess.

My unit is set up in a permanent place - and positioned to use the passthrough, so I have room behind the unit to put the muffler. It’s 12” long… so depending on your set up, it might not fit.