I did two cutting boards - one came out perfect and the second one had uneven “burning” from the laser. Is this an issue anyone else has had. I also noticed that some of my cutting boards have it much darker on the first few rows of the image and then it evens out. Is this a calibration issue?

Are you sure it was the laser? Not all cutting boards are created equal.

Different woods, and different densities in the same piece of wood, will react differently to the laser at a constant power and speed.

Just a thought.

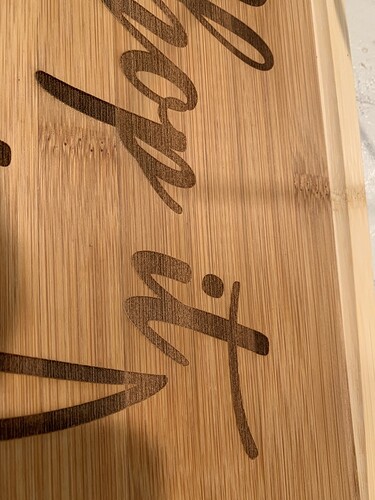

I am moving this to Beyond the Manual since we are discussing non Proofgrade materials. All wood responds differently to laser engraves. Bamboo is even more variable as it isn’t actually wood. Your results will be effected by your focus method, your speed and power settings and the variable nature of the wood. Maybe you can share photos of what you are seeing and we can be more helpful.

I just uploaded a pic of what I am talking about.

That’s unfortunately due the variations in your bamboo board, there’s nothing you can do on the laser side to mitigate that.

Ok - at least I know it’s not me. LOL

Agreed. Look how the engrave changes as it goes across the different sections of the board.

I have worked with a good bit of bamboo and Acacia, and the seem to be the worst offenders for me. It is the wood and not the laser. I find that most people understand that it’s not like a single board with a more consistent grain. It happens the you glue and place different boards together. Inside grain, outside grain, densities and growth patterns all come into play in wood. Every individual piece of mother nature is unique.

This ^^

the composite of the different pieces is the first clue. The pieces that are laminated together differ in maturity and the grain of what is essentially a grass (monocot grain) glued - laminated. The material is not uniform by age or structure.

Exploring the different materials was my biggest thrill regarding the effect I could have on them.

Test All The Things!

I’m starting to get to the point where I find myself studying the wood for a while (bamboo included…I love working with bamboo, it’s always a surprise!) looking for the changes in wood density and grain so I can work my design into what nature has already provided… I don’t always get the results I hope for, but sometimes I get more!

I love that, better than you envisioned. ![]()

I agree with them. ^^^  The good news is this is 100% the material and not the laser. Bamboo a giant grass and the boards are made by laminating different pieces of grass together and they will all burn slightly differently. If you happen to get a board with similar pieces laminated next to each other the difference isn’t so noticeable, but sometimes the differences can be quite noticeable. It’s just the nature of the material though and you either have to embrace it or try a different material.

The good news is this is 100% the material and not the laser. Bamboo a giant grass and the boards are made by laminating different pieces of grass together and they will all burn slightly differently. If you happen to get a board with similar pieces laminated next to each other the difference isn’t so noticeable, but sometimes the differences can be quite noticeable. It’s just the nature of the material though and you either have to embrace it or try a different material.

One thing that can help mitigate it can be using a brush to really clean the engraving as this can even out the tones a bit. You can also try something like coffee to stain the lighter areas, but that can be hit or miss.

Thank you all soooo much for all the information. I love this community. I am new to the laser world and have recently added this to my business so your insight is invaluable.

It doesn’t take long to get a feel for the different materials and what to expect from them.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.