So last Tuesday, I was with some of my church family at the building and it was brought to my attention (or maybe more of “Can you fix it?” request) that something needed help.

In the kids room, there is an old overhead projector that I had only a few weeks before replaced the bulb and now it won’t even light the power LED.

Climbed up the ladder and sadly pronounced it dead (as Doctor McCoy would tell James T. Kirk).

Some begins the panic and concerns. I knew we had at least one projector else where (we moved into this building in February and had upgraded projectors). Problem was people moved things around to how it made sense to them and we also had an off-site storage room.

Of course, the people who had moved things around and those who had the key to the storage facility were not available. Thankfully, while digging around in some storage boxes, YES I found a projector!! Weird thing is, I don’t know where it had come from or even if it worked ![]()

Showed it to several people and one person said, “Oh yeah, that one was in the kids room at the old building!” HUH??? News to me. Got thinking so where did the one that died come from ![]()

Verified that the newly discovered one work and asked, “Where’s the mounting hardware for this one?” Crickets and blank faces ![]() .

.

Which brings me to my first functionally creative (just not artistic) project…

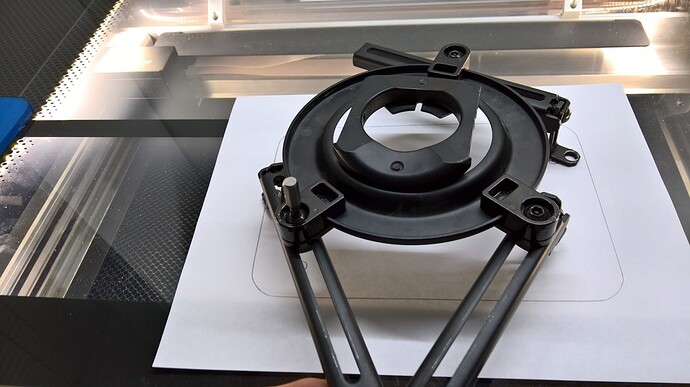

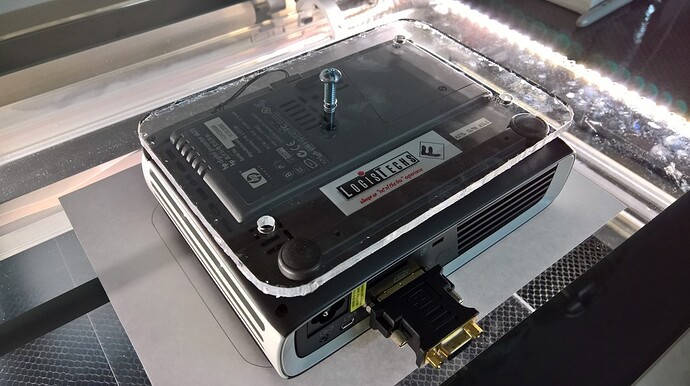

The suspect (belly up)

With a single tripod screw connection.

Since my software design skills need serious improvement, I though I could just use the trace feature. Now I just happened to have a test cut of acrylic that was the right size for a mounting pad. Positioning it on the belly of the projector, I determined where I needed to place 1/4 inch holes. Grabbed a piece of blank paper and (use to GF ![]() as an illumination table) I traced out the shape and hole locations. Panic… I didn’t have anything that hade a 1/4 circle. Asked my wife if she had anything with a 1/4 hole and she brought me one of here sewing template tools that the hanger hole fit the bill.

as an illumination table) I traced out the shape and hole locations. Panic… I didn’t have anything that hade a 1/4 circle. Asked my wife if she had anything with a 1/4 hole and she brought me one of here sewing template tools that the hanger hole fit the bill.

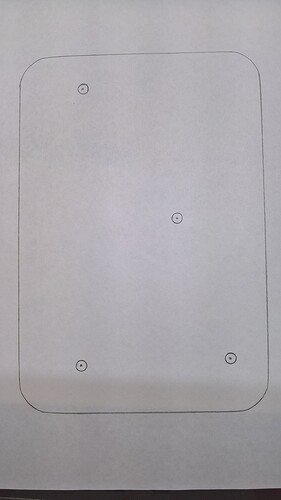

So thing is what I started with

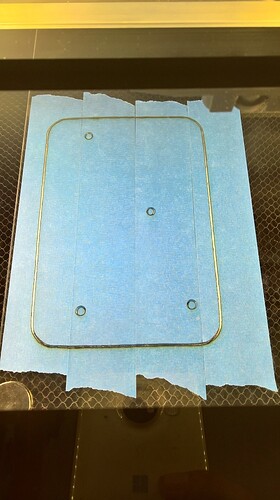

Having some 1/4 acrylic, I blue painter taped it (for depth measurements), did the trace acquire and cut this on Kòptis ![]()

Now the cast acrylic (non-PG) required running it twice because I cheated and lied to Kòptis and the Glowforge servers that it was thick clear acrylic…

Now the mounting contraption is incredibly ugly, so I will let the pictures speak for themselves.

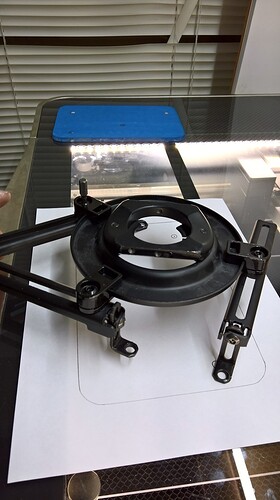

Once I figured out screw adjustments and arm positions, here is the end result.

So up early Sunday morning to install it before the kids get in.

Did forget to say I told them it won’t be ready for this Sunday, but thanks to getting the Filter delay prompting vent changes success, it is ready to go tomorrow. ![]()

![]()