Well this is frustrating; the jig-alignment method has failed me.

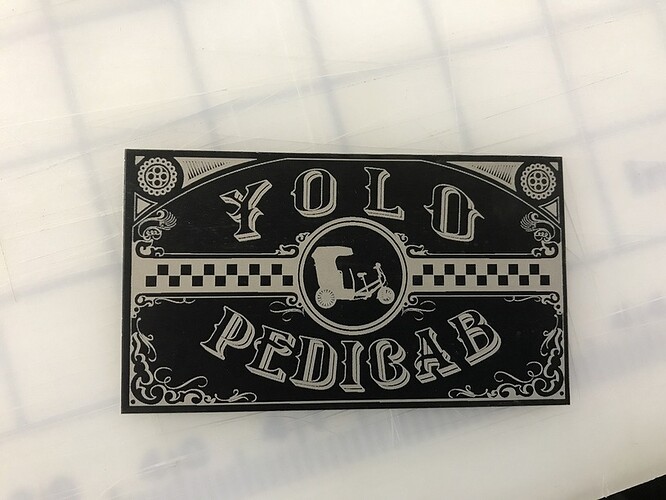

I have an order for 50 anodized aluminum business cards, engraved on both sides. I did 25 of one side last night, using a cut-in place cardboard jig. It took a while, but worked fine.

This morning I was going to do the other, more complicated side. I had a fair idea that they would not all be able to process at once, so I tried to plan around that. I had set up an svg with an array of 25 cards (a 5x5 grid), with the art for each side split into 1 color per row to be able to turn off rows of art, and cutlines in a different color.

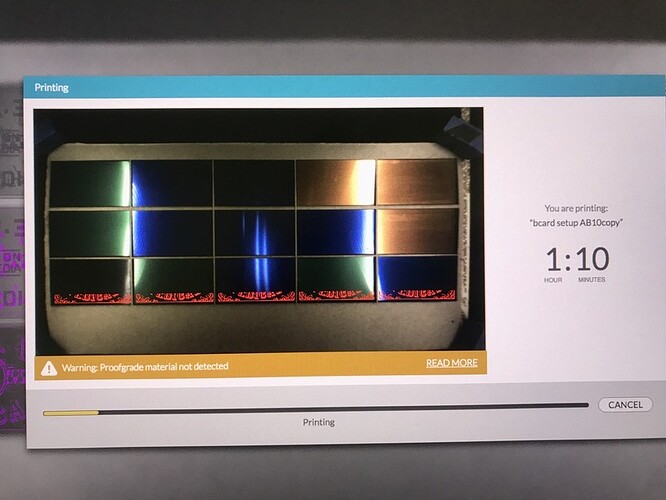

That was too much to process, so I removed two rows. 15 cards processed into the GFUI. Looking good.

I turned off all the art steps in the gfui and sent just the cutlines to print on cardboard. That worked, but I didn’t get all the way through the cardboard, so I ran the job again to get all the way through. The cut lines fell exactly where they were supposed to on the second pass. Looking good.

I put one aluminum blank into the newly cut jig, and started a test engrave, to be sure of alignment before running more at once. Problems occurred. So I deleted another row and tried again. 10 cards actually ready to print. Looking good.

Ran the test on one aluminum blank. Alignment is close enough. looking good.

Put ten blanks into the jig, started up the print, looking good on the preview screen…

But not actually aligned anymore.

A quarter-inch jump to the left, and 5 blanks ruined.

Gorramit. They were already going to take way too long, and now I’ve wasted some of the time that I put in last night. Guess I’m going to try and finish these one at a time, and probably won’t offer them to any more customers, at least until I can be sure I’m not just wasting materials.

November 2 2017- Approx 11:00 am - Mac OS Version 10.11.6 - Chrome Version 61.0.3163.100 - GF PRO

materials and

materials and