Long post but these seem to get lots of likes and discussion. If you hate these, starve them of likes and comments and I’ll shorten them down.

Photo shows front/side/back view of my latest pen which is inspired by the Scarlet King Snake, indigenous in Florida where I grew up.

When laminating paduk (the orange-red wood above) it has a tendency to bleed into lighter woods. To minimize that I wanted to layer the paduk into something darker but keep some lighter colors in the mix. When I started laying out the parts, King Snake came to mind and it stuck.

The other design element inspired by the king snake was to use a mix of woods for the “yellow” bands. They are mostly maple but there are a few cherry and oak scattered in there more or less randomly.

So, what’s the Glowforge part? Cutting all those small laminations, of course! I made several 1"x6" blanks and cut them out inside of larger frames that will hold them for sanding.

This is another one of those cases where glued butt joints need to be mostly in-register. The face-glued joints will be much stronger, making the segment joints the weakest link.

No worries. Glowforge and a couple small sheets of veneer to the rescue. And the honeycomb hold-down pins. Those are invaluable.

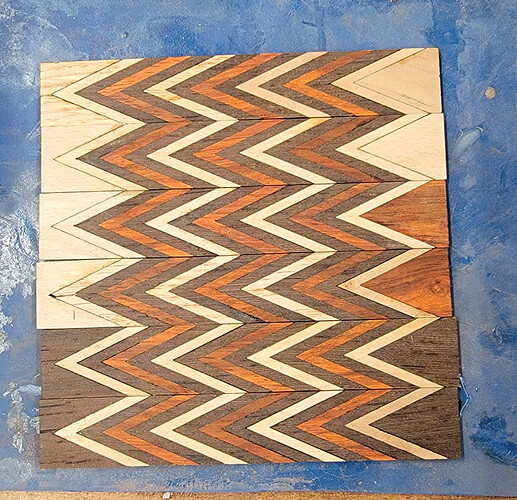

Here are the parts in dry-fit. The tops will be discarded once the blank is cut to length, but I thought the bottom sections might end up in the so I made sure there were a couple of each color. I went back and made two more with wenge bottoms after this was shot.

I used CA glue with activator, and glued these up by hand. No need to mask these for cutting because the flash marks come out when sanding the glue off the layers. The frames I made had too much play in them to use during gluing but they sure did help hold the layers together for sanding. The stack at top are glued and sanded layers.

You know what they say - if there’s room for another clamp, you haven’t used enough clamps. In this case if I’d thought about it, I would have used clamps vertically on the ends to help keep the layers in register. Luckily I snuck by this time and the layers stayed close to true register.

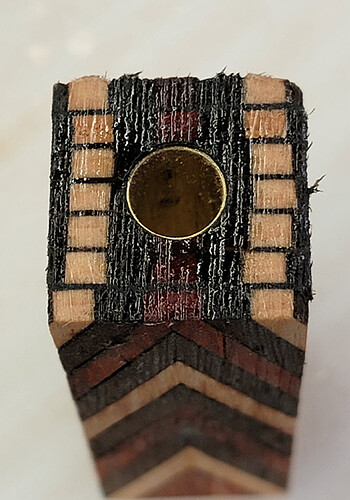

Note the layers of veneer between the pattern layers. These provide structural stability with a face-glue joint that spans the stacked butt glue joints. As a design element, it provides some boundary lines to make the layers more resemble snake scales.

Glued blank after clean-up. The registration is imperfect. Some of that is by design (snake feature emulation again) and some of that is inevitable. After stacking 14 glue joints in each layer, the layers themselves are not all the same length. This is evident in the top two layers which are closely aligned on the left but are off by about 3/32" on the right.

After drilling and epoxying the barrel tube it looks like I got the hole just a tad shifted to the left. I’m claiming intentional mimicry of natural snake asymmetry on this one. As predicted, most of the bottom of the blank was kept. I arranged it to keep as many of the red bands as possible.

After turning and finishing, the last step is to assemble the pen. Mostly this entails pressing compression fittings into the completed pen tube. Many people use their lathe or a vise as a press. This specialty tool lets me press the pen together in a cleaner space. An air-conditioned space. Sitting down. With optional alcoholic beverage now that no power tools are involved.

Finally, since this project was snake-inspired here are some identification tips.

- Coral Snake - Dangerous. Red bands between yellow bands.

- King Snake - Benign. Red bands between black bands.

- Choral Snake - Dangerous. That creepy guy in the choir who constantly hits on all the women. Wedding band removed but tell-tale tan-line is often visible.