I’ve got a brand new Pro with only 5 jobs so far. I started with cardstock just to get a feel for the work flow. The bed is clean, there are no materials obstructing the tracks, nothing bumping, and there is nothing obviously loose or odd. With the power off, the laser arm and head both move smoothly.

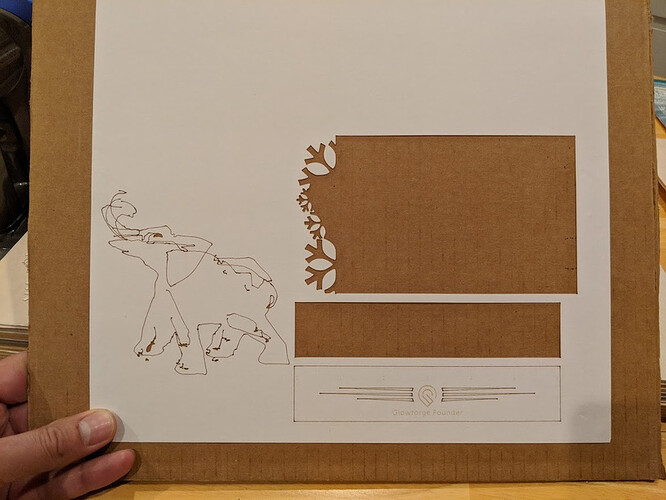

The first four cuts I tried were flawless, and then the fifth did something quite strange… An elephant svg was cut as scribbles:

New to the flow, I suspected I’d done something wrong in translating from Inkscape, so I went back and re-did the image. While moving to begin the next job, the laser arm skewed itself badly. I immediately stopped, powered down, and then manually aligned the head (centered under the camera) for calibration, just as the setup instructions had me do initially.

I’ve now attempted re-calibration multiple times. Here’s a video of one such attempt (2 minutes): https://photos.app.goo.gl/quqSo8CXHRKqQfKr1

The laser arm manages to align itself to be square with the tracks while under the center camera (around 1:23 in the video), but goes off-square when it moves towards the back (1:25). It’s as if the right side motor is moving faster than the left, as that side gets ahead whichever direction the laser arm is moving. When it stops at the back crooked, it seems to be under some tension. If I turn off the power, the left side “releases” and the laser arm moves towards square (around 2:00).

I have not attempted another cut. Re-calibrating from various positions doesn’t solve the problem.

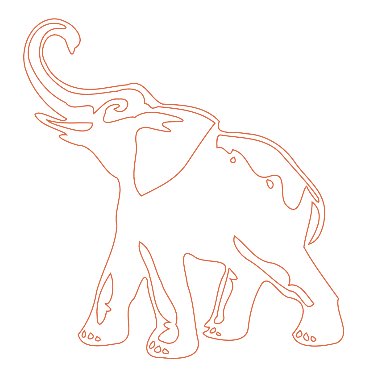

When I start calibration from the front, I end up centered like this:

If I start from the back, the angle is reversed.

Any suggestions?

Edit: Changed “carriage” to “laser arm”, the official term in the manual.