A big reason I didn’t cut first is just because I didn’t anticipate the debris buildup. In other words, I only noticed the buildup of debris after I noticed that the cut didn’t come out right. If I try this again (which I’m leaning against) I’ll see if I can come up with a good way to cut the bulk of the material out beforehand.

Oddly enough, cutting before introduces a couple problems and may prove to actually take longer (depending on the orientation of the engrave).

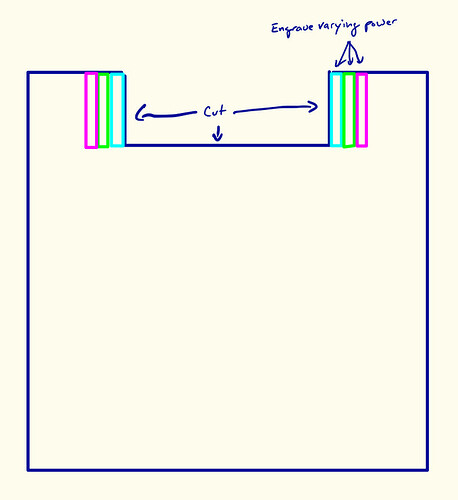

The problem I can anticipate is that cutting the piece out first will mean that the little piece has to be removed before continuing with the engrave. Of course, since the stock is sitting on top of the honeycomb tray, that little piece is going to fall out on its own 9 times out of 10. But the fact that the little piece isn’t guaranteed to fall out means that I’d have to check the part between that initial cut and the first engrave. For something like this where there’s only two, checking would not be a problem, but for a complicated set of parts with potentially dozens of slots, checking them all could become a bit of a chore. Then, if one of the pieces needs to be removed manually, that introduces a new problem: you’d have to make sure not to accidentally move the remaining stock while you go in with a little pair of tweezers or whatever (toothpick with a dab of superglue on the end?) to pick the little piece out. You’d have to be careful because moving the stock would mess up your alignment for subsequent cuts and engraves.

The way it could (technically) slow down the process is because the speed that the machine moves doesn’t necessarily change if the size/density of the engrave changes. The laser head basically swipes back and forth over the entire area that is to be engraved and then the laser blinks on and off very precisely in order to engrave whatever design you have. The speed of engraving a solid rectangle (where the laser stays on almost all the time) and engraving an outline a rectangle of the same size (where the laser would only blink for tiny fractions of a second during each swipe) will happen at nearly (if not exactly) the same speed.

Sorry, I don’t think I’m explaining this well… I’ll try again…

Imagine I wanted to engrave a giant capital letter “H”. At the beginning of the engrave it’ll only be doing the two points at the top of the two vertical lines. The laser head will start to the left of the first vertical line and sweep to the right side of the other vertical line. It’ll do the full sweep, even though the laser will only need to blink two times (one time for each of the two vertical lines). This will continue, with the head sweeping back and forth and the laser blinking two times until it reached the horizontal bar in the center of the “H”. At that point, the length will remain constant (from the left side to the right side) and the only thing that will change is how long the laser stays energized. Since the length of the sweep remains constant, the amount of time the machine takes to perform that sweep also remains constant.

So, only engraving those little patches probably wouldn’t shorten the time it takes to do the engrave. And the additional time taken to perform the cut would make the total job time slightly longer.

Not to negate everything I just said, but all this explanation only applies when the dovetail is oriented the way it was in my video (parallel to the Y axis, AKA “vertical”). If the part was rotated 90º the dovetail would then be parallel to the X axis, which would mean cutting the middle section out of the slot first would also translate to the machine needing to make fewer sweeps, which very well may reduce the overall job time.

Sorry for being verbose, I’m just trying to clearly answer your question.

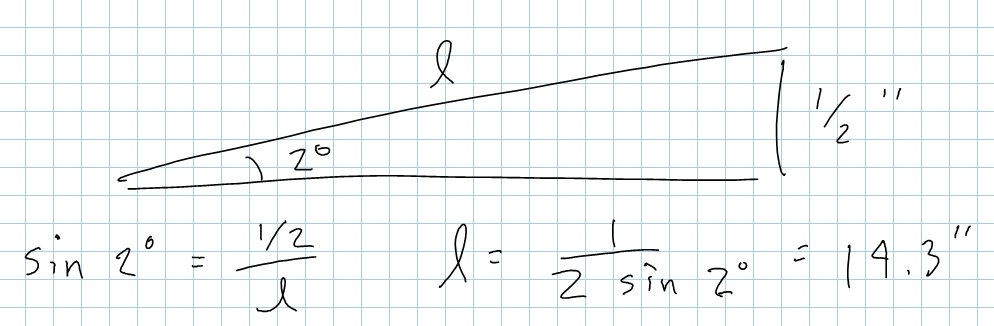

) and the offset from top to bottom is only .0087" (tan 2 * .25 = .0087"). Obviously on 1/8" stock it would be half that.

) and the offset from top to bottom is only .0087" (tan 2 * .25 = .0087"). Obviously on 1/8" stock it would be half that.