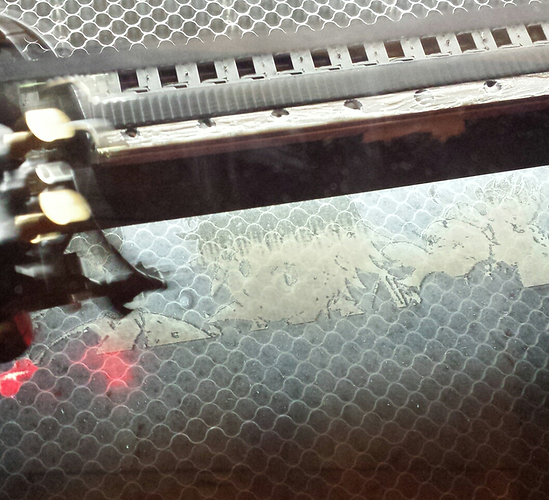

I just did this glass paperweight for my son in laws grandparents for their anniversary.

A bit tall for the glowforge but glass coasters etch very nice as well.

I am wanting to make a bunch of coasters. I have purchased the square glass coasters, I believe I saw some you did with a rose pattern, some multi colored sand stone square coasters and some light beige colored coasters (these are my least favorite I think). This is the site where I purchased them. http://www.glasscoasterstore.com/blankcoasters.html. Do I need to use cermark (I think that is what it is) on the sand stone coasters to get the laser to mark them?

Gorgeous! Have you ever tried to use your laser to make a score line on stained glass, to cut it? That’s one thing I’d really like to try.

It doesnt cut the glass deep enough I wouldnt think…but may try it sometime in the future😁

I bought the same glass coasters…dont know about the sandstone…would have to look that up😜cermark is used for metal

I believe I read somewhere that someone bought those sandstone ones and it ended up bleaching the color out when it passed over.

How do you prep the glass and at what power and speed?

I tried hitting a glass sheet i found at menards, i soaped it, but went to wash it and it came out pristine. Only the soap fried off.

Cermark has formulations for glass & ceramics. They have 4 colors available now. Thermark also has formulations for glass & ceramics but I don’t know if it’s just black. (Thermark bought Cermark so I’d expect anything Cermark did that Thermark didn’t will cross product lines.)

It’s been awhile but I think I used 100mm/s @65% power (on a 60w laser). Cover the glass with a wet paper towel or newspaper. That helps cool the glass as you etch so it doesn’t spall or fracture.

It melts the silica which is what glass is made of…so yes, it gets lighter. If the sandstone was dark, it would work, but for light colored, you cant really see anything without a color fill.

Oh yeah, I forgot about that…Ive used Thermark for years…keep forgetting they merged…

Probably not going to ever use the glass or ceramic formula but would love to see how it does…

I use a thin layer of dishsoap. 35w laser…100% power and 45% speed but these numbers are relative to each laser so you’ll still have to tweek it.

Some suggest doing 100% power and speed equal to the laser wattage…so 40w laser 40% speed.

I did a little looking and found this. They used the tape as a mask to mark some marble. Looks promising, because I have a few of the very light beige sand stone coasters that I want to use somehow.

I am not sure what the little dots are on each of the pieces. Maybe some artifact from the cad program?

My guess is stars…umm astronaut and comet or satelite in space…lmao

Marble seems to be a pretty hard smooth surface I wonder how it will stick on sandstone?

I don’t know how deep or even if the laser will indent the surface, but paint in the grooves might be ok and not wear off too fast. I have never used a laser so I don’t know ANYTHING.

Ive done flagstone which is soft like sandstone and was able to get depth. I would do colorfill myself…

I went to your website and saw the knives that you had engraved. Is that something that the Glowforge can do without filling etc.? Those are really handsome knives and I would love to be able to make some as gifts. Are there places to buy them in small quantities, like 5 or so?

Thermark on the knives. My son in law worked at a gun shop and got discounts but now he doesn’t…lol

haven’t priced them yet.

Website is a bit sparse at the moment but my daughter is working on it hopefully next week to get it up and running… it’s just a place holder for now…

Aren’t the dots registration marks for the sensors on the laser ?