There is something you need to check.

1. Turn off the machine.

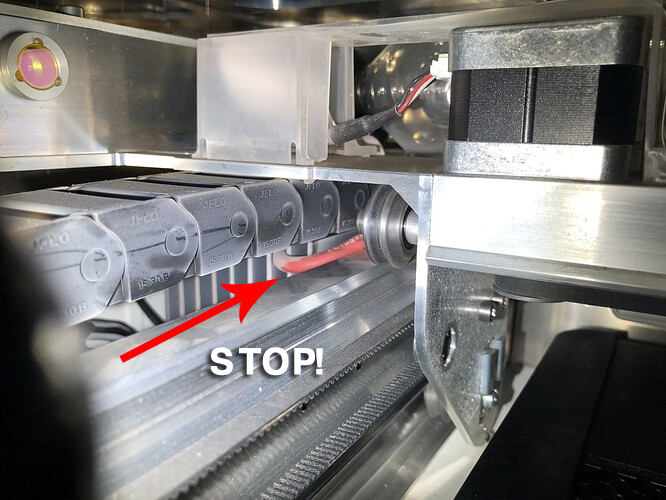

2. Lower the front door, use a flashlight and get down so that you can see underneath the gantry on the left side.

There is a red cable that runs the length of the gantry, you can see it through the tube if it is clean…locate that cable, keep your eyes on it and slowly push the gantry back to the rear. If you see the cable catch on the fins of the heat sink or feel any resistance, stop.

If you see that happening, you can CAREFULLY adjust that cable following the instructions at the link below.