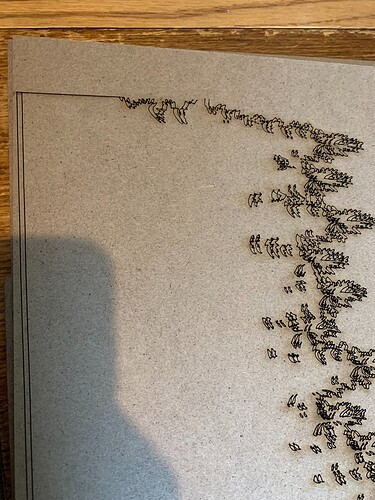

I have tried all I can think of to fix this problem. I’ve cleaned everything. I’ve turned things off then on. I’ve used proof grade material to see if that would re-orient the laser. The only thing I can think of is tension on the side belts. Tension is totally fine, based on the video tests via Glowforge. However, the right belt does seem SLIGHTLY tighter than the left. Could that possibly be the issue? I can’t tighten the left so only option is to loosen the right one but couldn’t do it (screw too tight for me). Is there ANYTHING else it could be? If it’s a matter of making sure both belts are PRECISELY the same tension, then does anyone want to buy a Glowforge? I’ve barely even used it and have had nothing but little problems like this.

Mine is doing the same thing today! But not on every cut…beginning to think its on the GF side and not my issue.

If that’s the case, then: Glowforge FOR SALE lol.

Have you ever had that issue before? I’ve been having this problem for a week. Extremely frustrated.

No, first time I have had the issue.

Did you email support@glowforge.com yet? If not, do it now, because it can take a minute to hear back. Glowforge staff doesn’t read the forum – you’re asking for help from other users like you, and we don’t have all the tools and info that GF support staff does.

While possible, pretty unlikely. I cut today without issue, as have many many others. I suspect we’d be seeing a lot more complaints if GF had some new software problem.

More likely than anything is that you have a physical problem.

Unfortunately, there are lots of possibilities, too many to list in one shot. The best bet is to narrow it down.

Turn off the glowforge and slowly move the gantry front and back. Are there any spots where it binds? Try to see if anything is causing friction. (I had a screw that wasn’t properly all the way in and it was rubbing intermittently once. Caused all kinds of problems)

Move the head from side to side, see if it binds anywhere.

Now do the extremes, move to the corners, see if it moves freely.

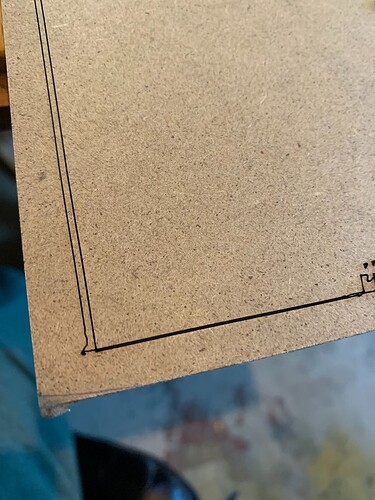

If that all checks out, now think about your materials. Were they sticking out past the edge of the tray? The gantry supports move front and back, if your material is too wide, it can hit that and cause all kinds of alignment problems.

The list goes on and on. Let us know what else you find.

Would you kindly report what settings and material this happened on. Sometimes a very fast score can cause a problem, or a tiny bit of debris on the rail or in the belt, or the material extending over the honeycomb tray. Also, if you would care to share the file, someone could try to repeat the problem.

I wish I had an answer for you, but just here to say I’ve had the same issues this week for the first time ever. It’s so frustrating. The only thing that’s helped temporarily (and it’s not a good solution) is letting the machine rest a day. I was able to get a few good cuts in before it went back to being distorted. I’m so sorry you’re dealing with this.

A physical issue like a cracked wheel or debris on the rail would not resolve itself with ‘rest’, so that points to a failing stepper motor or the drive circuitry.

How old is your machine?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.