Never used a laser cutter before. I’m also a bit of a miser. I also believe that playing with something like this is a good way to learn more about it. So, before getting to material that costs money, I decided to just play with cardboard. Used the forum’s search function and used:

to get started. After cutting a few founders rulers, I settled on 215 speed/60 power for the cut and went with a shot in the dark for engraving with 1000 speed/15-35 for power depending on the color I wanted, wich worked great. Haven’t really settled on a score setting yet. It can be difficult if you are not scoring with the corrugation, I think.

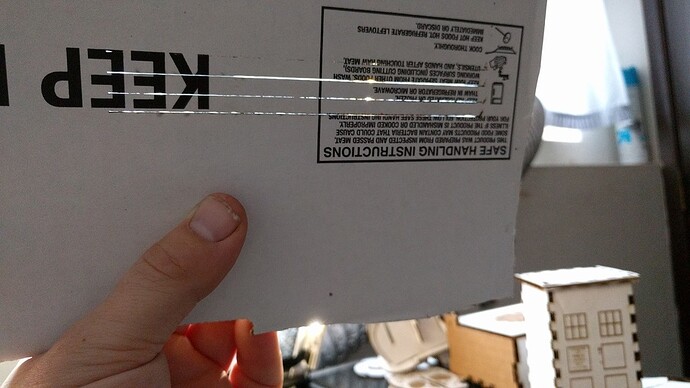

One thing that I did not figure out right away was how to put material thickness in for non-Proofgrade material. You just click in the corner where it says:

Unknown

Unknown

If it were Proofgrade settings, it would be something like:

Medium

Cherry Plywood

Anyway, what you see here are the following:

- Founder’s Ruler from the Glowforge catalog

- Puzzle from the catalog with an image I drew added as the artwork

- A tabbed box generated from http://www.festi.info/boxes.py/ that is meant to fit on one of the 6x12 solid hardwood Proofgrade sheets

- Several items from http://www.thingiverse.com

Laser Cut Jewelry Boxes by antpgomes - Thingiverse

Skull 3D pens holder by LesMarco - Thingiverse

Tardis : Laser cut cardboard version by t4obrien - Thingiverse - A tray I created to try out using a single file to print out a multi-layered object that had been scaled in the UI

So far this has been way easier than I expected. There have only been two bumps in the road at this point. The first was when the 'forge tried to do it’s very first calibration and the head, which was placed all the way to the right following the setup manual, tried to continue in that same direction eternally. Having been an unhealthily avid reader of the forums here, I figured I could try just moving the head directly under the camera. The machine was off and, because the setup manual specifically says to do it during setup, it was unplugged. Worked like a charm, but I’m not the only one that has had that happen.

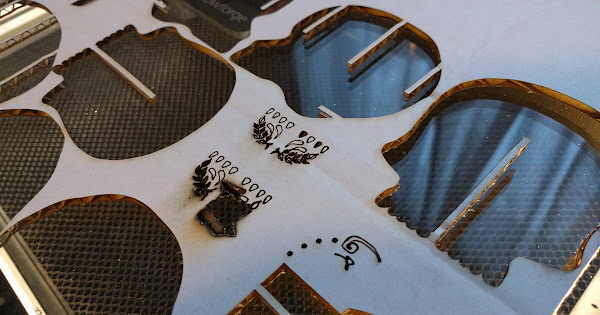

The second “bump” was all me. It did make me appreciate the warning information that the Glowforge UI provides regarding using non-Proofgrade materials, including cardboard. I was attending my machine at the time, so a lift of the lid was all that was required. Here it is:

I accidentally chose to “score” the decorations rather than engrave for one of the tries on the skulls. Had the power level set to 30, like I would for an engrave. Way too much for cardboard. Luckily, that was the first operation. So, I was able to rearrange things around the torched spot and not waste my precious cardboard. Tried to score it again with power set to 1 with results that were more encouraging and less um… fiery.

One more note on cardboard: it provides a large “fudge” factor for things like scaling a design to smaller than it was originally. Normally, that’s a problem for tabs and slots and stuff and wood or acrylic or whatever. There are two skulls because the first one I scaled too small, even for cardboard’s forgiving nature. I used the Glowforge’s UI to rearrange the pieces to allow me to have to scale it down less. The original is made for bigger material than I happen to be using.