Yep, that was me, a few posts above

Finally fixed my lid!

Here I’ve detached the black cable/strip, removed the lid, and carefully removed all the old glue.

I next removed the back/top strip INCLUDING the hinges and removed glue from the matching side. (And took no useful pictures.)

Then I cleaned with alcohol and used JB Weld Clear to join the parts. Since I removed the hinges it was easy to join the sides once glue was applied, still detached from the Glowforge.

After curing I reattached the hinges (and now attached lid).

So far so good!

I love this! My machine just passed the 7 year mark, but I have some interest in posts about the lid coming unglued because before I got my current machine, I had a pre-release and the only reason I had to send it back was because the lid was coming unglued.

And then? How did it go?

I have one of the original crowd-funded GF Pro machines. It still works flawlessly, but every time I clean it I look at the hinges, dreading the day… Your process looks like a good one if/when the time comes.

I’ll keep an eye on it, but it’s rock solid so far. I’m hopeful that my thorough cleaning of the surfaces and my more generous coverage will make this glue job last beyond the life of the other components.

Bookmarked this! Thanks for the explanations.

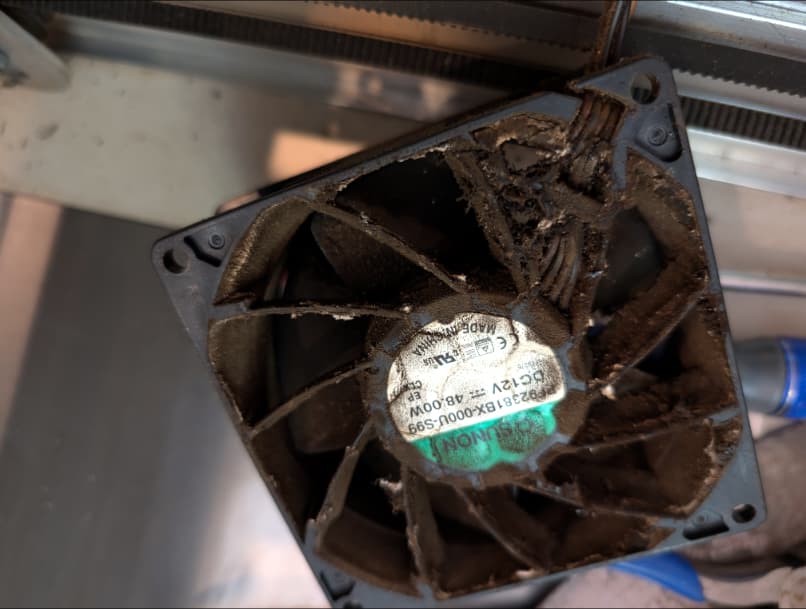

So that’s what a clean tube looks like…I haven’t seen mine that way since I got it.