So I received my Glowforge basic today! I couldn’t be more excited! I do have a question regarding the lid though.(the question is at the very end) I also thought I would share my experience for anyone interested.

This is how it arrived.

The UPS guy can’t read the arrows pointing up apparently. I would have corrected it, but my arm is in a sling from shoulder surgery, so I had to wait for people with 2 good arms to help.

The box was a little rough, the bottom looked like it was going to fall out, and it was missing all but one of those clever white handles. (Will I need those to ship back for tube replacement?)

I was actually able to see the glowforge through the handle holes. I was surprised there wasn’t a protective film on it, but it arrived in decent shape.

I got it unboxed (with help again) and gave it a once over. I did notice a few aesthetic imperfections. This is a small scratch on the front. With the surface finish of this thing though, it is bound to get many more after years of use, so I am not really worried about it.

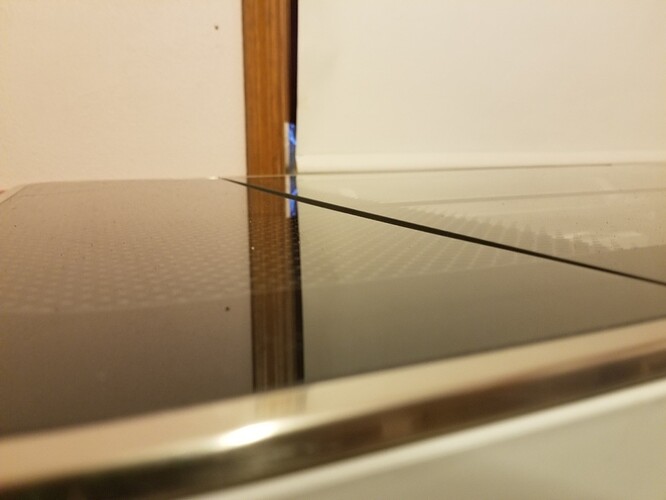

I also noticed this “residue” on the top of the left side glass. Seems like a silicone or glue type residue. Again not a big deal. I may be able to rub it off with my finger. Not sure if there is a “safe” solvent for this. After waiting 2 years, I am happy that it’s sitting in front of me. The QC at Flex could maybe use a little improving though.

Turning it on for the first time was impressive! I was amazed how fast those bubbles disappeared. As someone who has had to tip a k40 laser cutter on its side to get rid of bubbles, this thing was beautiful to watch! Shortly after though I did get the amber light that indicated that it was too warm for it to “finish” printing. I wasn’t printing, so I think that is just a general temp warning. I was a little worried about that. I believe it was about 81 or 82 degrees Farenheit in there. After a quick trip to the hardware store, and a new air conditioner in hand, I was back in business!

Anyways I cut the glowforge “ruler” and it worked flawlessly! The one thing I did notice, and is also the point of this post, is that the lid is not exactly flush with the top. The top lid and sides are made out of some pretty thick glass, so I am not exactly sure how this is possible, but it seems like either the lid, or both sides of the machine are slightly bowed. I am thinking it’s the top of the sides. I will place a yard stick on them tomorrow to be sure. The lid sits flush in front and back, but at its midpoint the lid is about 2 to 2.5mm higher than the sides. I tried to take a picture, but I am not sure if it will convey it properly. All I really want to know is if this is normal (within tolerance) or if this is a slight defect that I need to fix. It cut the ruler just fine, and it looks like it gets a good seal, but I still wanted to check. Anyone else have this problem?