If nothing else, this thread has proven that with the Glowforge, just about anyone can learn how to use a laser cutter.

Ahhh…thank you. I did not understand that. I will now sleep better with no visions of piles of small dead animals around a glowforge exhaust outlet while the laser itself melts into a pool of toxic sludge ![]()

![]()

![]()

@dan, I am moving this thead to #problems-and-support and requesting that it be closed.

When you are seeing red to such a degree that you can’t see the direct defense of something it may be time to take a break sir.

LOL, ouch, I’m sick as well. And yes, as usual from you, good advice.

No red. Just trying to see through all of the attacks. Nothing more. Pure mistake.

Man, I wish I could find a supplier like that. Especially the 1/8 inch (3mm) stuff. It’s been very hard for me to track down in the SAN Antonio area.

In that case, the whole sentence to you man

This topic is temporarily closed for 4 hours due to a large number of community flags.

This topic was automatically opened after 4 hours.

This topic is temporarily closed for 4 hours due to a large number of community flags.

This topic was automatically opened after 4 hours.

This topic is temporarily closed for 4 hours due to a large number of community flags.

This topic was automatically opened after 4 hours.

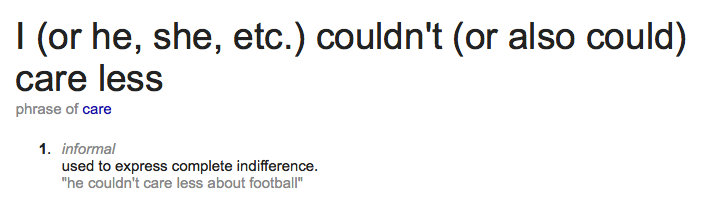

After reading this entire thread, your last sentence seems to be an accurate description of the problem. While we’re on that topic, the term you mean to use to indicate how little you care about something, is “I COULDN’T care less.” Saying you could care less means you do care. It could mean you care more than you’ve ever cared about anything, because you could care less. If you don’t care at all, then it’s not possible to care less. So, “I couldn’t care less” conveys your intended meaning. This is all pretty self-explanatory, if you just look at the words and understand their meanings. I guess the amount of explanation needed for so-called self-explanatory terms varies with the individual, much like the results of attempting to make your own bootleg version of Proofgrade will vary widely depending on the materials used and the skills of the user. To attempt to clarify something that you seem to keep missing, regardless of how it’s presented or how many times, no one was accusing you of starting your own Proofgrade store and trying to steal money from Glowforge. People were simply suggesting, and in a friendly manner, that you don’t suggest your end product is the same as actual Proofgrade material, because it’s not, it can’t be, and that term only applies to the materials sold as Proofgrade materials by Glowforge. To further illustrate a problem with your use of the term, people mentioned, half-jokingly it seemed, that the Glowforge lawyers wouldn’t like it. I also think the fact that you started with a material not even offered as Proofgrade material, in your attempt to make your own version of Proofgrade material, means you don’t quite have the materials and skills required to duplicate the materials as well as you seem to think you can.

To dumb it down for you even further, since I assume that will be necessary, if you had said, “Hey everyone, you can sand down some plywood and throw some shellac on it to get similar results to using Proofgrade materials,” no one would have said a word about legal issues or anything of the sort. You probably would’ve gotten some responses suggesting that you wouldn’t get the consistent performance expected from Proofgrade materials by making your own version, but that’s pretty obvious to most people… not all… clearly.

In the future, when you decide to get overly defensive when someone dares to question you, try not to attack everyone else before trying to play the part of the victim. I hope this helped, though I assume you’ll respond angrily without actually comprehending any of it. Happy New Year!

You literally just spent quite a bit of time trying to explain to me how I used a specific phrase incorrectly. The issue is that you didn’t really do your research on the phrase itself. Like others, you assumed something and rolled with it. Quite a bit with it actually. It then led to insults, like others, hidden in with you trying to speak intellectually.

I understand that you felt like you needed to add to the conversation and beat a dead horse. After doing a little bit of research it seems that the common denominator in the whole issue is that you and the few others that insist on trying to insult “intellectually” so that it seems as if you are educating me all have each other in common. You all seem to be each others favorites, or best friends, on this forum, hence the term, pack of rabid wolves.

The truth of it is that you and your “pack” came to an assumption, began accusing, and keep it going with further insults with each comment. Although, you have attempted to hide them in exhaustive rambling trying to sound intellectual.

You took this comment and assumed I was saying that you could make PG material exactly. I don’t know if you just chose to skip over the words “pretty much” in your assumptions. Pretty much does not say exact. It means very similar. I used birch as an example because it isn’t offered as PG and it is cheaper. I figured that some might find it helpful in practice because it is a much cheaper alternative when you don’t need PG materials. I also spoke of the shellac and vinyl transfer tape because that is what really makes the PG a good reliable material. It limits the smoke staining and provides a smooth finish after you remove the tape. This technique can be used with any material to achieve better results straight out of the machine. No matter what wood is used. I use it on dang near everything unless the project would benefit from a different finishing method.

To say that one can not make PG (without the name. Don’t want to open that can of worms again) exactly is also just asinine. Some have found inconsistencies with PG material. It isn’t the “perfect” end all be all. It’s literally, from my guess, MDF and veneer. I could be wrong though. With the right tools and/or machines (drum sander), you could easily get perfect results each time with thickness and consistency.

You guys think I am a vicious victim and I think you all are just a group of old guys that have nothing better to do but gang up on someone and try to talk above them. All over an assumption that one of your crew came to without trying to clarify. It’s okay. Your wolf pack is safe. I just don’t think you guys can see the forest for all of the trees. No insult but just my opinion that the assumption is based off of tunnel vision.

Enjoy your machines. I enjoy mine. I was just trying to suggest to people using shellac and vinyl transfer tape on other materials that they can’t get from the Glowforge store. It doesn’t exactly have a huge selection nor does any other site like Inventables for example. I buy my lumber in rough form, usually, and cut it down myself to thin stock. I used BB as an example because that’s what I use to “play” with to save ruining exotics. It is just extremely easy to sand it, shellac it, tape it, laser it, and peel to get end results similar to PG. It eliminates smoke staining which is the biggest benefit. Also saves delicate sanding and the risk of losing detail to remove the staining.

i completely agree with this.

This topic is temporarily closed for 4 hours due to a large number of community flags.

After reviewing this topic, a few notes:

- Please review the forum guidelines. There are many forms of conversation that are appropriate elsewhere (between friends, on other internet forums) that aren’t appropriate here. This forum is, to summarize briefly, very G-rated.

- There are lots of great conversations about materials that are sold by other vendors in the Beyond the Manual section. We welcome those conversations; I’ll move this here.

- Proofgrade is a trademark of Glowforge. We welcome people discussing it and comparing other products to it; of course, other products shouldn’t be labeled as Proofgrade.

- Due to a quirk of how the forum & support software interact, our support team doesn’t see posts that are moved to “Problems & Solutions”, just new posts there. So please don’t move posts to that category; instead, create a new post there.

- Proofgrade material is finished with a UV-catalyzed laser-compatible finish. Shellac is a finish with different properties - it’s what I used to use with my first laser when I was experimenting in my garage. (Also it’s what I used to finish our walnut coffee table; not laser-made). It’s great stuff.

Be careful with heat and water, as both will degrade shellac quickly. Ask my coffee table.

Be careful with heat and water, as both will degrade shellac quickly. Ask my coffee table. - Since this thread has attracted a lot of flags, I’m going to close it (it was previously temporarily auto-closed by the forum software). Feel free to create new topics to explore different materials & finishes.

I really welcome everyone’s contributions. I appreciate the passion each person brings to this conversation. Please treat each other with the respect and decorum requested by the forum guidelines so that we can all benefit from each others’ experiences.