MakForge Field Trip Report

Okay, so everybody here is already aware of the generous Glowforge sharing that @marmak3261 has been engaging in. Turns out he does that in person, too. My husband and I were invited to lunch and demo at MakForge headquarters and we took him up on the offer yesterday. What a wonderful experience it was!

First order of the day, after the tour of all the ‘forged samples you have already seen (although there is no substitute for in-person observation–the quality of the engraving on his matchbox holder was just stunning), was Glowlunch:

It featured homemade shredded ham sandwich fixings along with homemade pea/ham soup, homemade rye bread, homemade pickles, and cheese slices (forgot to ask if they were homemade as well?). Super yum!

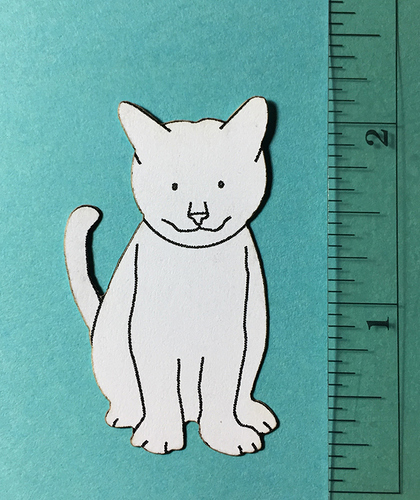

We got down to business pretty soon after that. I had brought a bunch of the cat stampings that I do for my cards, as I’m very interested in Glowforge’s performance with paper laminated to craft foam as well as its performance on multiple images at once. I also supplied Marion with Illustrator outlines of the images so we could compare auto tracing with cut files.

And let me apologize in advance for the vertically oriented video—I wasn’t thinking clearly at the time even though I knew better. Please don’t throw tomatoes! I also didn’t document the visit very thoroughly, I was just too excited and in the moment!

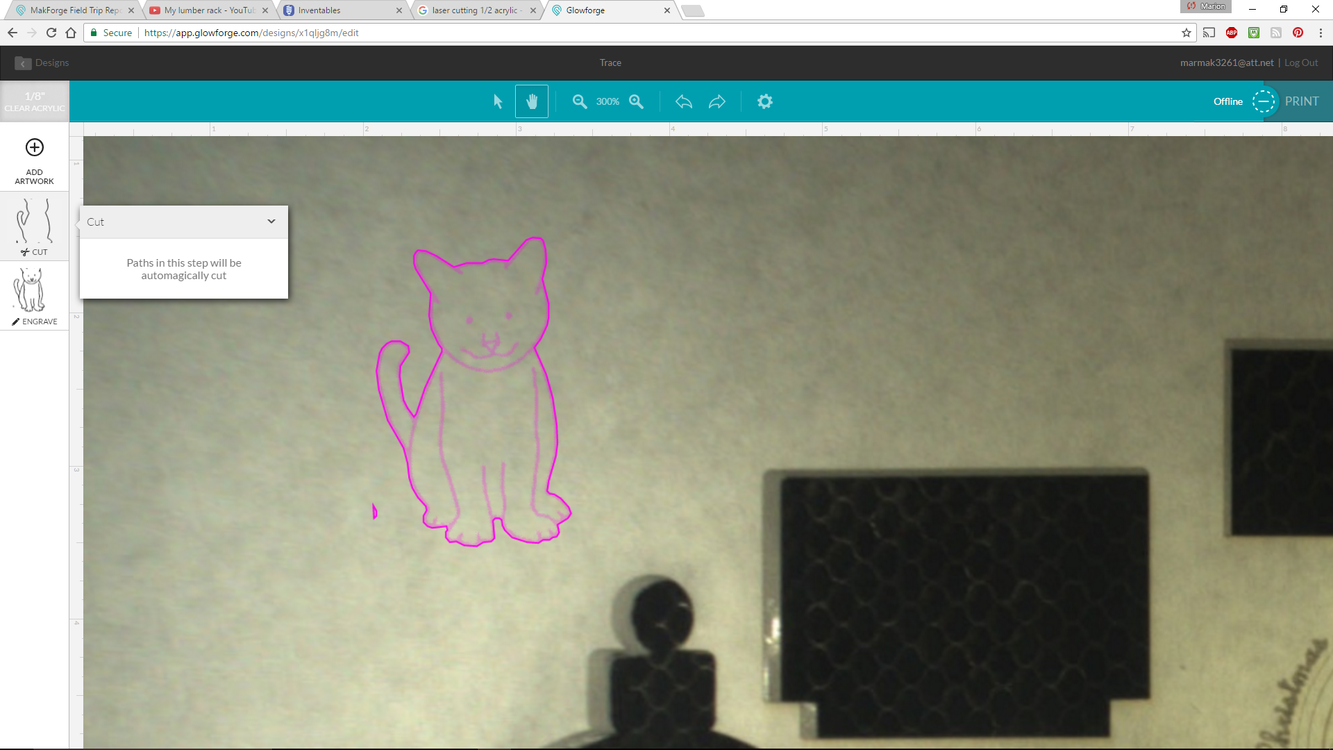

First we tried auto tracing one cat of a group printed on plain card stock:

Holy smokes! The accuracy is amazing!

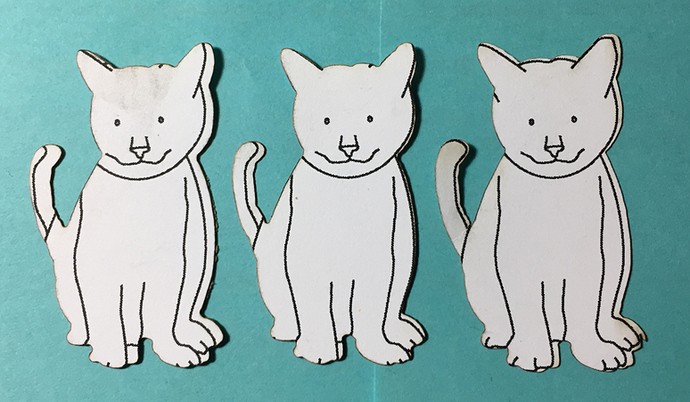

Then for grins we decided to try autotracing three separate figures at once. I don’t believe this is an advertised capability of the Glowforge but it might be in the hopper.

Results: oops, unusable. Okay, no problem, we have an outline cutfile.

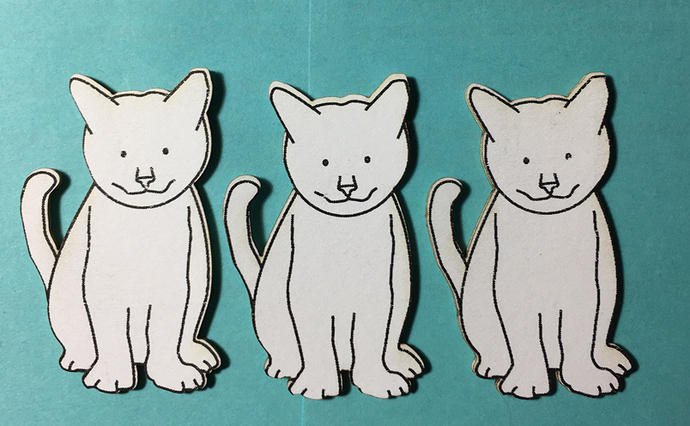

Oh yeah. WAY better. Still a tiny bit off but improvements are no doubt on the way. I can see a consistency in the discrepancy, and that should make it easy to fix either in the software, or in my placement of the files over the bed scan. These three cats were cut out of card stock that had 1mm thick craft foam laminated to it to make 3D stickers.

After that we cut out 3D stickers from a sheet that I had previously colored with Copic markers.

The cool thing is that it didn’t cut quite all the way through the base carrier sheet, effectively resulting in a kiss cut (yes, you CAN do it!). So the individual stickers can be peeled off the sheet leaving the others attached until needed. Woot!

Eventually we moved on to other materials: solid walnut that had been cut and planed by Marion, a piece of leather donated by @drea (thanks!), and an acrylic name plate for edge lighting, cut from Proofgrade 1/8.” Here’s a group photo:

We also cut a cube out of 1/4" thick craft foam, which I failed to get a photo of.

Oh by the way, our operations were supervised by one of the most dignified yet laid-back cats I’ve ever met, Cole (no, he is not plugged in despite the appearance in this photo):

Before we left, Marion presented us with a parting gift, a bottle of his Private Vintage red wine vinegar. Awesome, and hard to top!

All in all a delightful day, with the nicest person (and cat) imaginable! The Glowforge access only whetted my thirst a unit of my own, pre-Release or otherwise. Soon!