I had a similar thought to @evansd2 here.

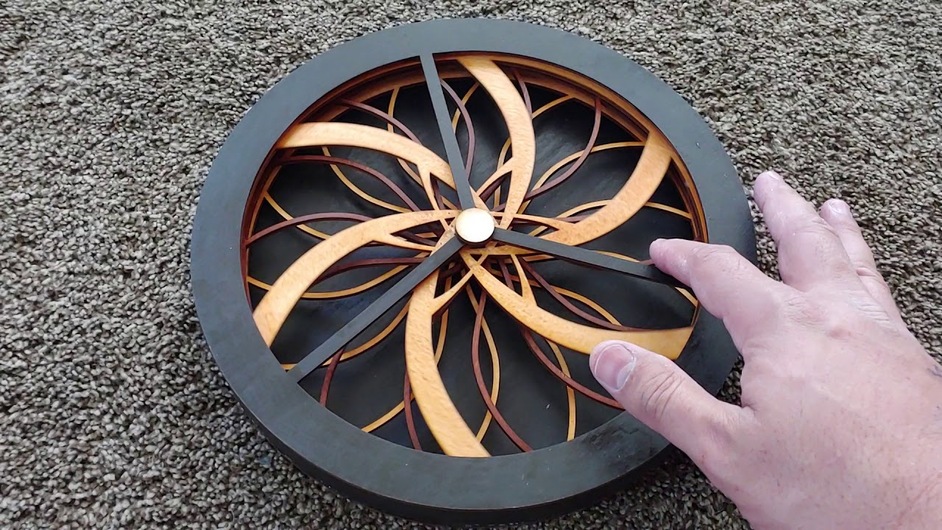

The design is no where near as complicated as the ones evansd2 is working with, but here is what I came up with:

Each layer is 3mm stained baltic birch. The interior has 3 layers that spin independently (there was a 4th, but I broke it during glue up). The outer border is layers of rings (more on that below).

For the movement, I used 10mm ball bearings around a central brass rod. The rod is held in place between the top and bottom layers. Because the ball bearings and the birch were about the same thickness, I had to place a small ring between each bearing as a spacer to allow them to spin freely.

One of the biggest challenge was dealing with wobble at the edges. To compensate, I put a stabilizing layer every other layer in the border to sit between each of the spinning layers. To reduce friction, this stabilizing layer had three tabs that stuck out and sat between the spinning layers (that is what you are hearing).

Overall, I am pleased with the result. I learned a ton (and was REALLY glad birch plywood is cheap).