I am looking for a tape that I can mask wood, acrylic and also make stencils for sandblasting glass. Some pieces acrylic that I have don’t have tape on them. I have seen lots of different types of vinyl tapes listed on the forum, but is there “one” that would be good for all the applications? Also, I have read that folks are leaning toward 12" wide tape. I was thinking of 6" wide tape because I would think that the 12" would be hard to work with and it would be more economical since I have some smaller material to cover. What are your thoughts on width?

Why not have a roll of each? Then use whichever one suits the project at hand. Then, with time, you’ll recognize your own preference - not at to horrible a cost, I should think.

@jbv had recommended https://www.signwarehouse.com/c/transferrite-ultra-582u in one of his posts, but I don’t know if I can use it to make a stencils for sandblasting glass. I saw some glasses that @smcgathyfay “Laser Lady” made. They were beautiful, but she has one of the rotary jigs for her laser. Since we will not have one, I want to sand blast mine.

Slick. It looks to me like the price is the same for the area - 12" is twice the cost of 6"… so not more or less expensive for what you get.

Thanks for the link.

As to the sandblasting… somebody else must say. I have no knowledge.

the transfer tape will not hold up to sandblasting. There are sandblasting films, but the ones I have used are either vinyl or rubber, and I do not know how the rubber ones would laser cut. They cut beautifully with a plotter and a 60* blade.

LazerMask seems right but pricey, LaserTape is cheaper, and I have heard good things about Anchor #116 and #117 (polyester) for laser/blast combo.

@jbv, would the transfer tape hold up to the chemical etching cream?

My gut instinct is that it would not, but I’ve never played with etching cream. I would be afraid that the cream would weaken the paper of the tape and it would become increasingly difficult to remove, even if the cream did not compromise the stencil shape itself.

Someone can (please) correct me if they know better.

From what I know electrical tape works well. (for sandblasting)

My vauge understanding is that the cream works with vinyl stencils (how I’ve done glass etching before) because it doesn’t interact with the vinyl/plastics specifically. I’m willing to guess that the paper and adhesive stuff won’t stand up to it. When we switched to a sandblaster, even the vinyl had a hard time holding up, but I was using thinner stuff (all weather sign vinyl).

Just be aware that most electrical tape is made from PVC so you won’t be cutting it in your Glowforge

Are you making your stencils with a laser? I’ve done a lot of sand engraving on glasses and plates and have always used vinyl w/o many problems. However, that’s using the silhouette to make the stencils - the laser on vinyl isn’t a good match. They do make laser mask material for sandblasting, but you apply the mask and then laser before you engrave deeper with sand blasting. Thus, unless you have a rotary attachment, you can only do flat glass objects. Have you looked into photo resist masks from Rayzist? Nice if you want to sandblast detail and photos onto glass or stone.

If you do it this way, without weeding, you would just be sandblasting the cut lines themselves, and not doing any sandblasted “fill”. that could be a neat effect for outline letters or if you were going to paint portions of the design afterwards. You could also then weed select parts of the design to do a “fill” with a lighter touch/less abrasive media, outlined by the lasered cut lines. This method would only work for us with material thin enough to fit in the bed of the glowforge.

You can also laser the mask by itself, weed the design (weeding is the process of removing all the bits that you just cut out), apply transfer tape, stick the whole thing to your workpiece, remove transfer tape, blast away. Some folks like to weed sandblast and stencil material after applying it; I only do this if I am working with spray-paint and want to use the one stencil with multiple colors, removing select portions at a time.

Just found this stuff on a Canadian Engraver Supply site when I was looking for some other stuff:

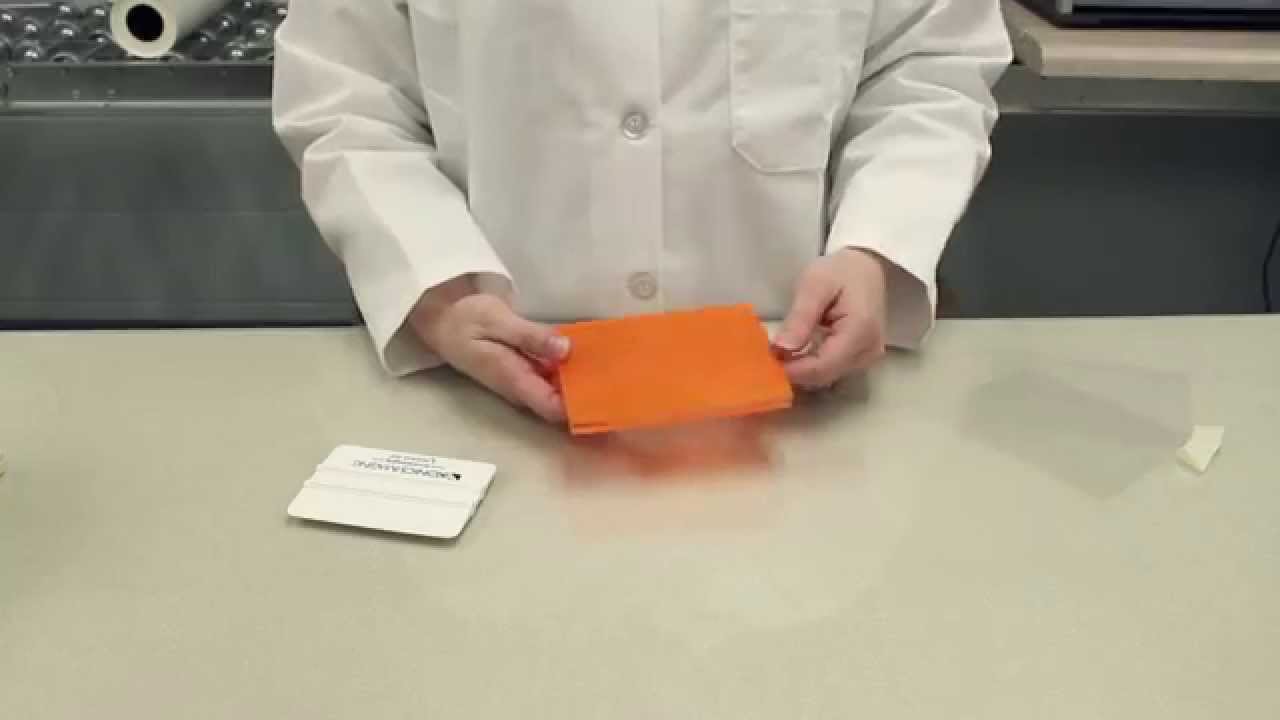

Laser Mask Blazer Orange

Laser Mask Blazer Orange is a sandblastable laser mask designed to create stencils for the high end corporate, promotional products and giftware industries creating beautifully etched glass and crystal. Film turns slightly darker when in contact with substrate, allowing you to see if areas are not making good contact.

Adhesive does not leave residue on the substrate. Easy dry peel.

More durable allowing for a deeper blast, making it great for colour filling.

Stretchy enough to wrap but maintains its shape when wrapped.

Does not stain substrates.

Available in 6” and 12” widths.

Yes - that’s the tape IKONICs sells as well (that I saw at the NBM show) as well as a less expensive http://ikonicsimaging.com/lasertape.html laser tape (I picked up samples of this one, but have not tried it-don’t want to waste with the Chinese laser…)

It is possible to achieve a remarkable level of detail and shading using larger and smaller grain size blast media.

From Flint shot and powder fine silica up to coarse grain “play” sand, the resulting textures transmit the light differently.

Think of shading in a sketch in pencil or charcoal, between thinning the density of the blast and graduated grain size, the effect can approach 3D.

That’s a good demo. I have been working with a Silhouette and iron on transfers. OMG, it is tedious going back and forth with the transfer sheets and fiddling with the small bits. This explains it that the laser tape is ablated where the sand blasted image will appear so there is no need to fuss with transfers of small bits.