This is being reported by a couple of users.

I just had a quick look at the Glowforge information on the Proofgrade and it does not guarantee that it will cut right each and every time… however this is certainly something they need to fix ASAP - from a Brand and Trust POV

Info from Glowforge:

When natural products like hardwoods and plywoods are exposed to temperature and humidity changes, they change shape. This is known as “warp.” It is especially common after shipping or during the Glowforge printing process. In both cases, the warp will diminish with time. However, improper storage can cause permanent warping. Your Glowforge can print beautifully on materials with some warp, but here are some tips to reduce it.

- Give your materials time to flatten: Humidity and heat from shipping and printing may cause your materials to temporarily warp. If this occurs, unwrap them and store them, per the instructions below. They will relax, and their warp will lessen over the course of about a week.

- Store your material carefully: Upon arrival, immediately store your materials in a cool, shaded, dry place. Stack materials on a clean surface. Stacking warped material on top of other warped material can make the problem worse. To prevent discoloration or damage, keep them out of direct sunlight. If your materials need to be stored in a humid area, wrap them with plastic wrap or shrink wrap to keep moisture out.

- Set heavy objects on top of your material: To ensure your materials stay flat, stack heavy objects on top of your materials. Distribute weight evenly on top of the material. If possible, use a flat object like a textbook.

I had this issue as well and the Customer Success folks treated me right.

A way to save your work when it doesn’t cut through is to check for all the parts being loose without moving the piece. I do that with a hook probe. If everything lifts, fine, if not, you can repeat the cut and everything is good.

I’ve had this issue before. A quick (slightly time consuming) work around would be to take and xacto knife to the parts that didn’t cut through. The material left behind is very thin.

Or do what @markevans36301 suggested above.

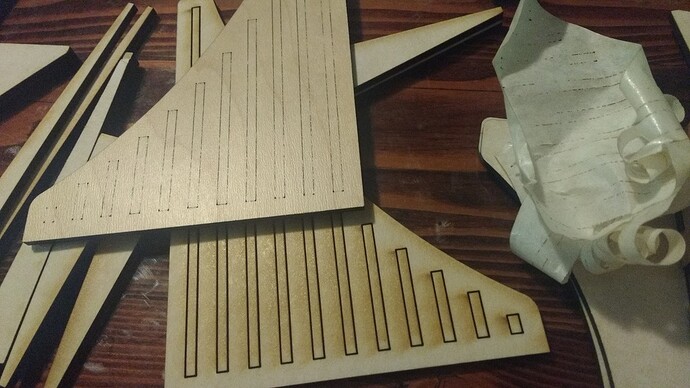

Thank you, everyone. The picture of the material was sent from my phone and then my computer updated, and I was not able to get on and make additional comments.

I was mostly putting this up to report it. There was some warping on the wood, however, on this piece, the back paper was pealing as well.

Also worth noting, this was also a design from the catalog. Specifically, the architecture bookend. I am not sure if the design just did not have and tolerance built in or if it was also the cutting issue, but it is taking A LOT of time to make the parts go together. This combined with the expense of the designs on their store makes me leary of doing anything other than using my store credit.

Yeah, it does kinda miff me that the proof grade materials do not work well all the time, as that is their advertising platform. As the cost of the proof grade is much higher than other materials, planning for even a small number of fails make proofgrade not make much sense cost wise.

My first ‘negative’ experience was with a Glowforge design using Proofgrade materials.

When did this change? I seem to remember that being a huge selling point of the material. Or maybe it was only for catalog designs that it was guaranteed, which this was.

Best of all, the paper has embedded codes that your Glowforge can read. This is absolutely magical. You may have heard that with lasers, you have to cut and engrave test pieces over and over again to learn the right power and settings, and you have to do it separately every time you use a new material. As you’d imagine, that’s a frustrating, slow, and expensive process. Proofgrade materials do away with all of that. Your Glowforge recognizes the material, automatically configures itself, and prints perfectly.

Doesn’t prints perfectly imply it is guaranteed to cut all the way through? Is there some weasel definition of perfect that gets them of the hook?

My guess is there is an environmental factor affecting the material.

I am on the high plains of Colorado, and my Proofgrade maple cuts perfectly. I have been through 25 sheets of it so far.

I am using a prerelease unit, but it was delivered just before production units started rolling, so it is close to if not the same build as a production machine.

I wonder if one of GF’s 50 sensors is a humidity sensor!

Not a bad idea considering one has been reported to have considerable condensation accrue overnight through the vent. “Electronics are powered by magical smoke, If the smoke gets out it’s no good”.

We want your catalog and Proofgrade prints to come out beautifully and very much appreciate you taking the time to let us know what happened.

As @scatterbrains said, warp could be an issue.

It’s also possible that your unit has an issue or needs cleaning. Would you please follow the cleaning instructions, and, while you’re cleaning, make sure that the Crumb Tray is sitting flat in the dimples and check closely for scratches on the lens or windows. When that’s done, would you print a Founders Ruler on Draftboard, and let me know how it goes? Thanks!

The lens and mirrors are clean. Also, it is worth noting that pieces of Proofgrade medium maple cut just fine both before and after this specific piece of proofgrade.

proof grade didn’t work? Use more (of your own) proof grade to check.

GF provides an extra piece of Draftboard over and above what was promised just in case Support needs us to run this test.

This is exactly what I do, though talk about a brand killer ;p It will cut 80% of the material 70% of the time we’re 50% sure! hahahah.

Jokes aside the support for this issue in my experience has been great.

They do? I didn’t receive any draftboard with my shipment of materials.

The sacrifice of being one of the first people to get a production machine. The Draftboard wasn’t shipping. Is now.

Wait… What?

They started this about a month ago.